Preparation method and application of modified egg white protein

An egg white protein and modification technology, applied in the field of protein modification, can solve problems such as increasing production costs, and achieve the effects of improving modification efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

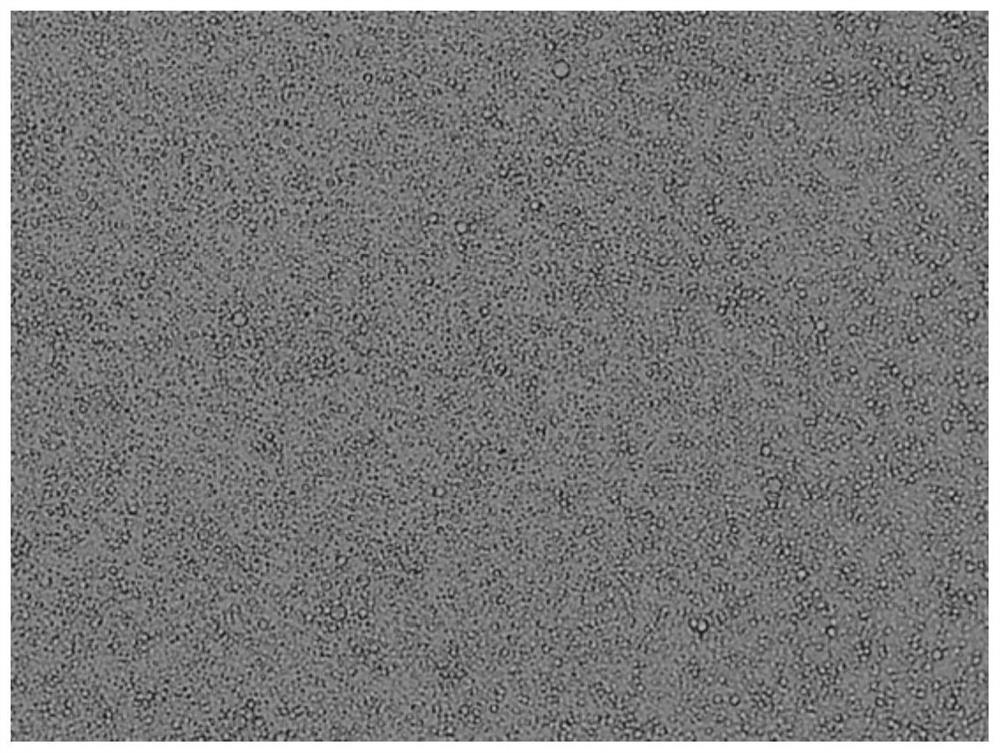

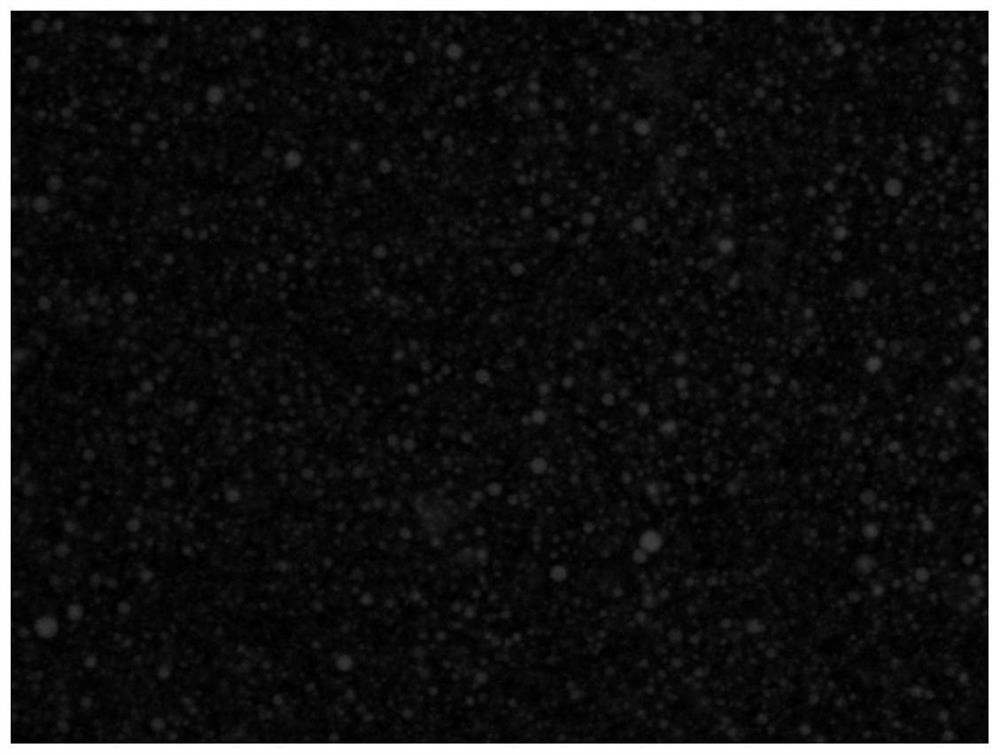

Image

Examples

Embodiment 1

[0057] Embodiment 1: Preparation method of stachyose modified egg white protein

[0058] Mix 70g of egg white protein powder (80.34% protein content as determined by Kjeldahl nitrogen determination) with 30g of stachyose and dissolve in 800g of water, then adjust the solution to pH 7.0 with 0.1M HCl or 0.1M NaOH. The mixed solution is separated by a ceramic membrane with a pore size of 50-500nm to remove insoluble matter. The parameters for the clarification and separation of the ceramic membrane are: the pressure is 0.5MPa, the temperature is 25°C, and the filtrate is collected and then spray-dried. The spray-drying condition is that the air inlet temperature is 170°C and the outlet air temperature is 90°C. The obtained egg white protein and stachyose powder were put into a constant temperature and humidity box for dry heat reaction at 60° C. and a relative humidity of 79% for 6 hours. The obtained modified egg white protein was stored at –18°C.

[0059] The EAI and ESI in...

Embodiment 2

[0060] Embodiment 2: preparation method of stachyose modified egg white protein

[0061] Mix 70g of egg white protein powder (80.34% protein content as determined by Kjeldahl nitrogen determination) with 30g of stachyose and dissolve in 800g of water, then adjust the solution to pH 7.0 with 0.1M HCl or 0.1M NaOH. The mixed solution is separated by a ceramic membrane with a pore size of 50-500nm to remove insoluble matter. The parameters for the clarification and separation of the ceramic membrane are: the pressure is 0.5MPa, the temperature is 25°C, and the filtrate is collected and then spray-dried. The spray-drying condition is that the air inlet temperature is 170°C and the outlet air temperature is 90°C. The obtained egg white protein and stachyose powder were put into a constant temperature and humidity box for dry heat reaction at 65° C. and a relative humidity of 79% for 24 hours. The obtained modified egg white protein was stored at –18°C.

[0062] The EAI and ESI i...

Embodiment 3

[0063] Embodiment 3: preparation method of stachyose modified egg white protein

[0064] The stachyose-modified egg white protein was prepared with reference to the method of Example 1, with the difference that the dry heat reaction temperature was adjusted to 45-70° C., and other conditions were the same as in Example 1.

[0065] Table 1 Effect of different dry heat reaction temperatures on emulsifying activity (EAI) and emulsifying stability (ESI)

[0066]

[0067]

[0068] It can be seen from Table 1 that the Maillard reaction speed is too low when the temperature is too low, resulting in unsatisfactory emulsification activity and / or emulsification stability of egg white protein. If the temperature is too high, the Maillard reaction will be aggravated, and the emulsification activity and emulsification stability of egg white protein will gradually decrease. Therefore, the preferred dry heat reaction temperature is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com