Disc pelletizer and method for crushing large pellets in disc pelletizer

A technology of disc pelletizer and large pellets, which is applied in the direction of granulation in rotating disk/pot, etc., can solve the problems of limited movement speed and impact force, reduced output of disc pelletizer, low crushing efficiency, etc., and achieves Avoid disturbance, realize automatic control and remote control, and achieve high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

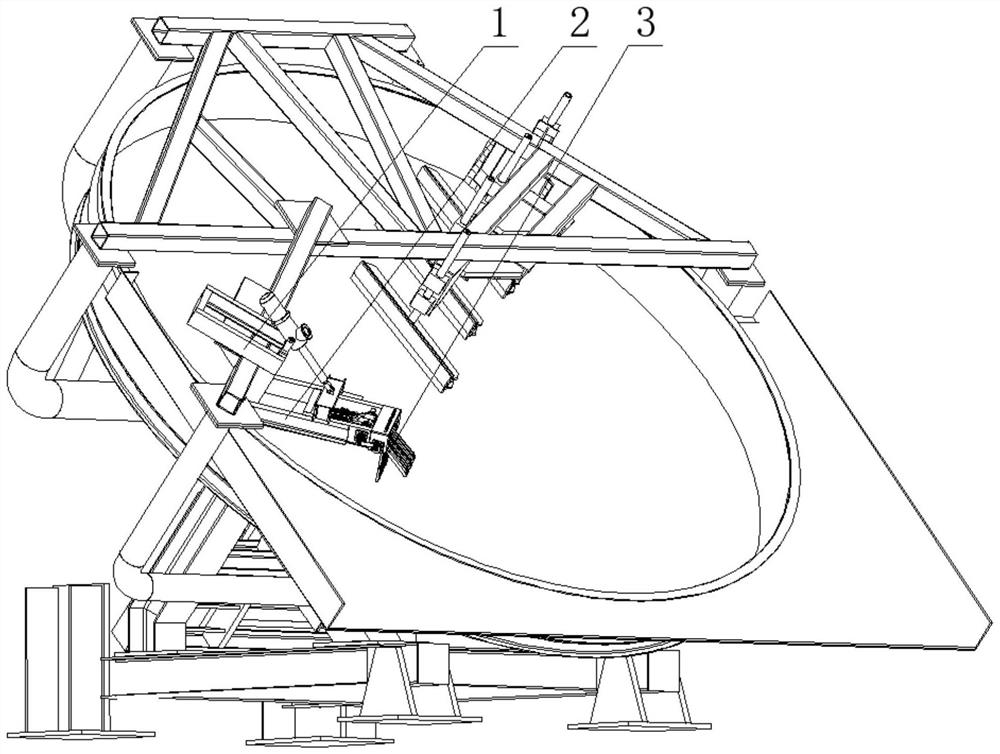

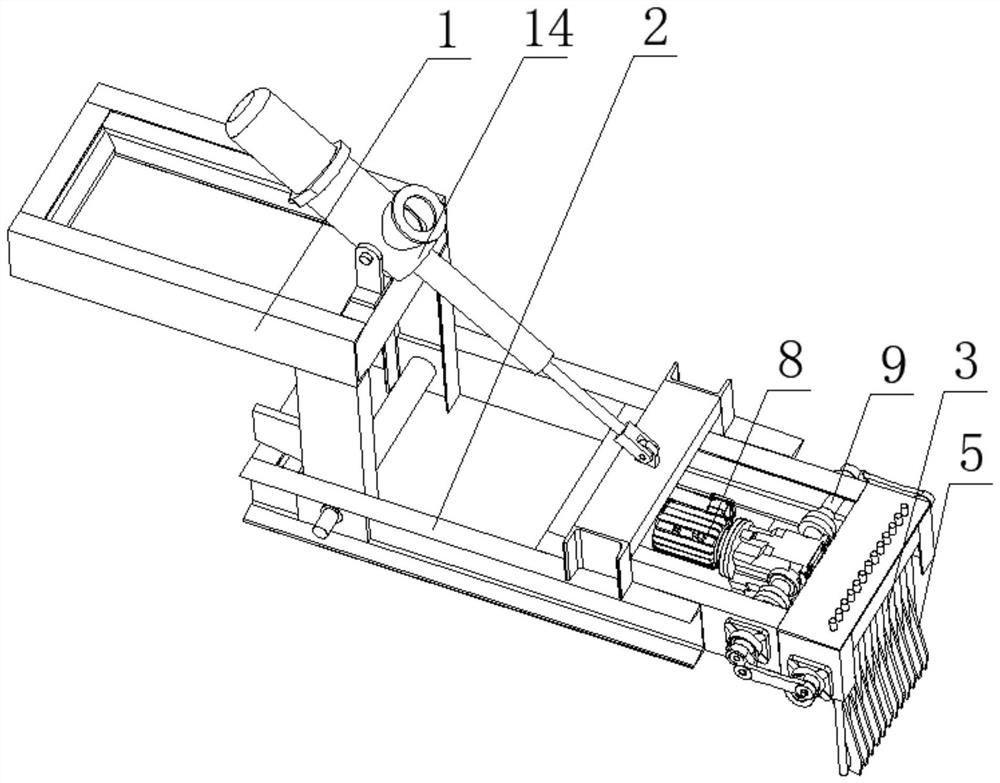

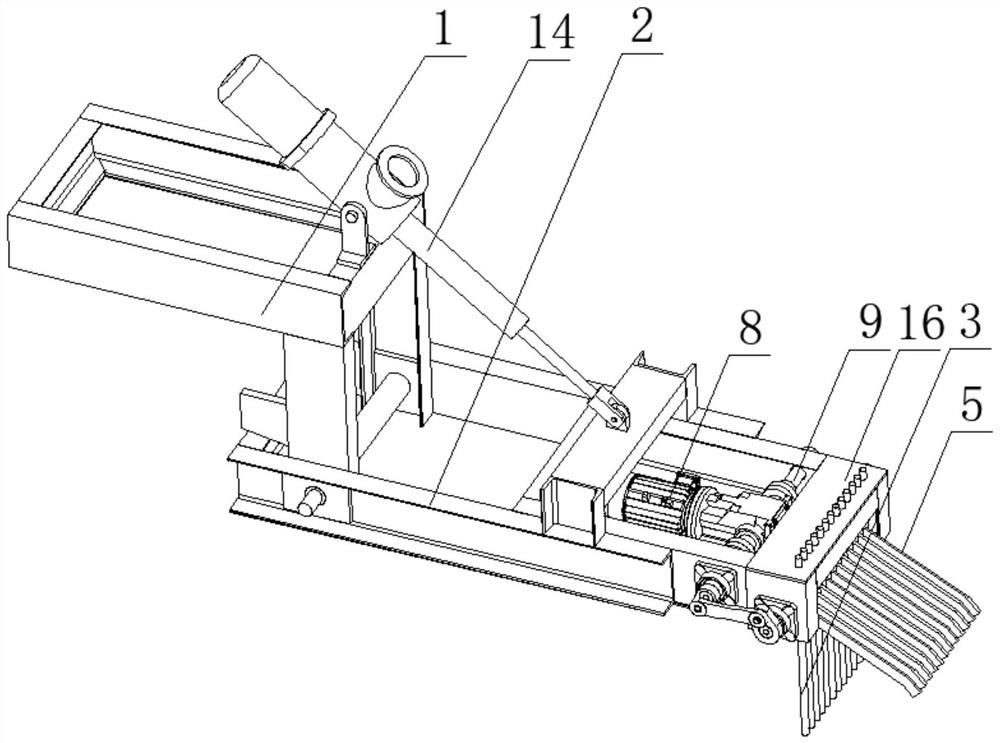

[0040] Example 1, such as figure 1 In the disc pelletizer shown, a beam is installed above the disk of the disc pelletizer, and a large pellet crushing device for crushing large pellets is installed on the beam. Such as Figure 2 to Figure 7 As shown, the large pellet crushing device includes a frame 1 connected to the beam above the disk of the disc pelletizer, a cantilever 2 whose first end is hinged to the frame 1, and a fixed rake tooth 3 connected to the other end of the cantilever 2, The rocker shaft 4 hinged with the other end of the cantilever 2, the movable rake teeth 5 connected with the rocker shaft 4, the first rocker 6 and the second rocker 7 connected with the two ends of the rocker shaft 4 respectively, and The drive mechanism 8 connected to the cantilever 2, the transmission shaft 9 that is rotationally connected to the cantilever 2 and is connected to the drive mechanism 8, the first crank 10 and the second crank 11 connected to the two ends of the transmissi...

Embodiment 2

[0044] Embodiment 2, as one of them, on the basis of Embodiment 1, the control system includes a three-dimensional laser scanner, an industrial computer, and a PLC controller; The pellets are scanned to obtain three-dimensional point cloud data and sent to the industrial computer, the PLC controller communicates with the industrial computer, and the PLC controller is connected to the telescopic mechanism 14 and the driving mechanism 8 for control. The pellet production process includes the following steps:

[0045] 1) Input the lower limit and upper limit of the number of large pellets that allow the diameter of the detection area in the disc pelletizer to be greater than the quality standard requirements into the industrial computer.

[0046] 2) The three-dimensional laser scanner scans the pellets in the detection area of the disc pelletizer in a timely manner, obtains three-dimensional point cloud data and transmits it to the industrial computer, and the industrial comput...

Embodiment 3

[0048] Embodiment 3, as one of them, on the basis of Embodiment 1, the control system includes a three-dimensional laser scanner, an industrial computer, and a PLC controller; The pellets are scanned to obtain 3D point cloud data and sent to the industrial computer, the PLC controller communicates with the industrial computer, and the PLC controller is connected to the telescopic mechanism 14 and the drive mechanism 8. The remote monitoring and control terminal connected to the industrial computer; the pelletizing production process includes the following steps:

[0049] 1) The three-dimensional laser scanner scans the pellets in the detection area of the disc pelletizer in good time, obtains three-dimensional point cloud data and transmits it to the industrial computer, and the industrial computer converts the obtained three-dimensional point cloud data into image data, and the obtained The image data is transmitted to the remote monitoring and control terminal in real time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com