Automatic packaging assembly line for sofa finished products

An automatic packaging and assembly line technology, applied in the field of furniture manufacturing, can solve problems such as time-consuming and laborious manual handling efficiency, difficult management, and customer complaints, and achieve the effect of reducing the risk of bending operations, reducing the burden on workers, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings.

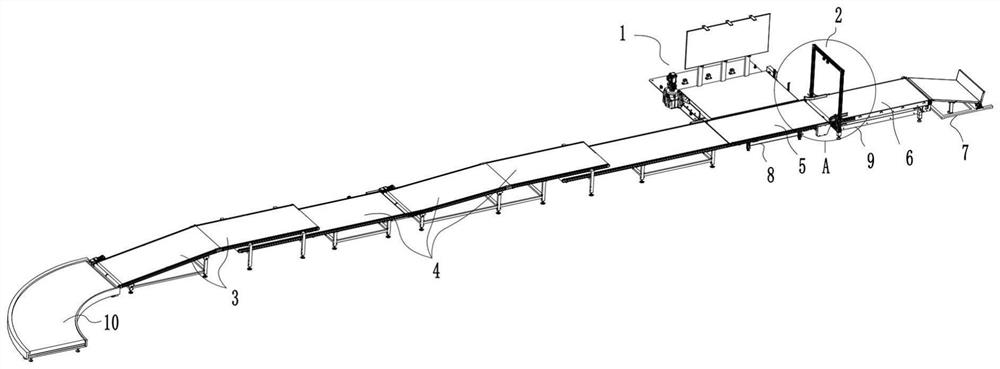

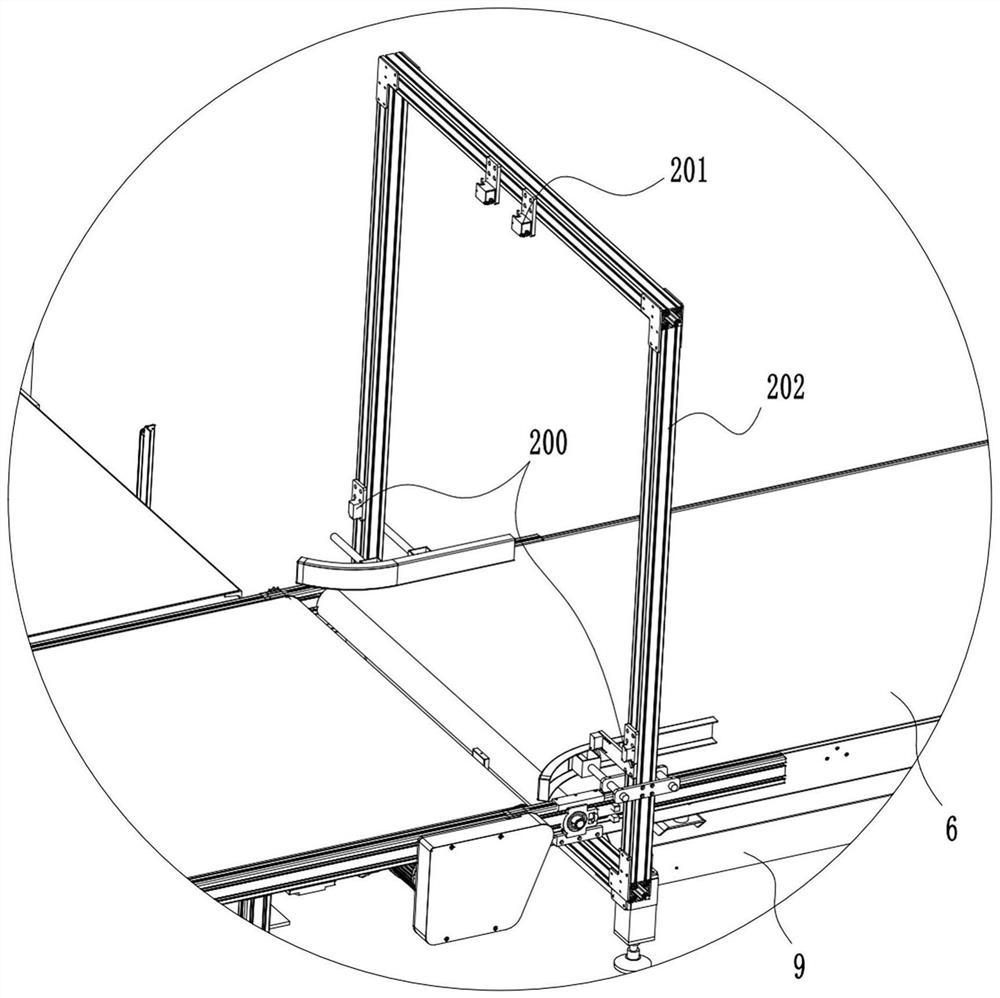

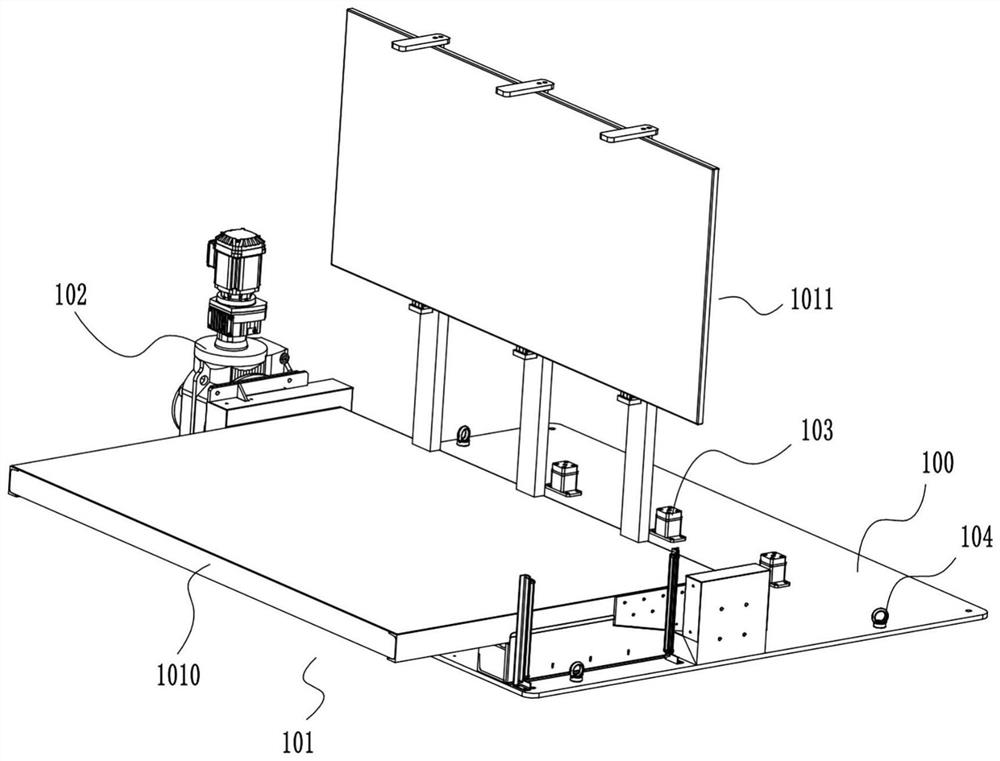

[0043] See Figure 1-7 A sofa finished product automation packaging pipeline, including conveying assemblies, carton sealing turret 1, and sofa volume measuring assembly 2, the delivery assembly for conveying the sofa, the carton sealing turning machine 1 is located on the conveying assembly It is used to flip the carton with a sofa, so that the opening of the carton is up, the sofa volume measurement assembly 2 to measure the volume of the carton.

[0044] Continue figure 1 The conveying assembly includes a turning conveying unit 10, a first climbing conveying unit 3, a second climbing conveying unit 4, a pack delivery unit 5, and a measurement conveying unit 6, a first climbing conveying unit 3, and a first climb delivery unit 3, and a first crawling conveying unit 3, and a first climbing conveying unit 3. The second climbing conveying unit 4 is equal to a high and low stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com