High-strength cast aluminum-silicon alloy part with complex shape for automobile and preparation method of high-strength cast aluminum-silicon alloy part

A technology for casting aluminum-silicon alloys and complex shapes, applied in the field of aluminum alloys, can solve the problems of high content, high cost of alloying elements, and inability to meet performance requirements, and achieve the effect of excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

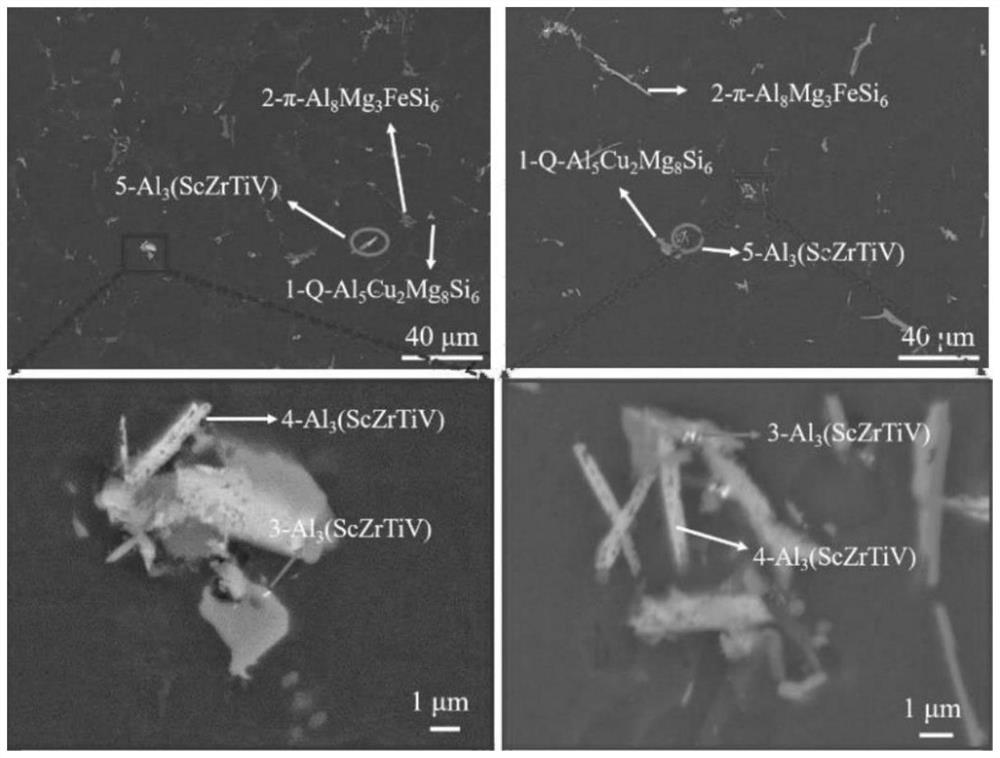

[0042] A high-strength cast aluminum-silicon alloy, the chemical composition of which is calculated by mass percentage: Si: 6.92wt.%, Cu: 2.26wt.%, Mg: 0.54wt.%, Ti: 0.12wt.%, Zr: 0.14wt. %, V: 0.11wt.%, Sc: 0.25wt.%, the balance being Al and unavoidable impurities.

[0043] The preparation method of the high-strength cast aluminum-silicon alloy, the preparation method comprises the following steps:

[0044] S1. Ingredients and preheating: Proportion weighing of raw materials according to the composition of the high-strength aluminum-silicon alloy. The raw materials are pure aluminum and aluminum-silicon, aluminum-copper, aluminum-magnesium, aluminum-titanium-boron, aluminum-zirconium, aluminum-vanadium, and aluminum-scandium master alloys ;Perform preheating treatment on the weighed raw materials, the preheating temperature is 200°C, and the preheating time is 30min;

[0045] S2. Melting: add the preheated raw materials in step S1 into a resistance furnace and heat until mel...

Embodiment 2

[0053] A high-strength cast aluminum-silicon alloy, the chemical composition of which is calculated by mass percentage: Si: 6.93wt.%, Cu: 2.98wt.%, Mg: 0.49wt.%, Ti: 0.12wt.%, Zr: 0.15wt. %, V: 0.11wt.%, Sc: 0.23wt.%, the balance being Al and unavoidable impurities.

[0054] The preparation method of the high-strength cast aluminum-silicon alloy, the preparation method comprises the following steps:

[0055] S1. Ingredients and preheating: Proportion weighing of raw materials according to the composition of the high-strength aluminum-silicon alloy. The raw materials are pure aluminum and aluminum-silicon, aluminum-copper, aluminum-magnesium, aluminum-titanium-boron, aluminum-zirconium, aluminum-vanadium, and aluminum-scandium master alloys ;Perform preheating treatment on the weighed raw materials, the preheating temperature is 220°C, and the preheating time is 25min;

[0056] S2. Melting: add the raw material preheated in step S1 into a resistance furnace and heat until melt...

Embodiment 3

[0064] A high-strength cast aluminum-silicon alloy, the chemical composition of which is calculated by mass percentage: Si: 5.5wt.%, Cu: 2.06wt.%, Mg: 0.45wt.%, Ti: 0.06wt.%, Zr: 0.08wt.%. %, V: 0.12wt.%, Sc: 0.15wt.%, the balance being Al and unavoidable impurities.

[0065] The preparation method of the high-strength cast aluminum-silicon alloy, the preparation method comprises the following steps:

[0066] S1. Ingredients and preheating: Proportion weighing of raw materials according to the composition of the high-strength aluminum-silicon alloy. The raw materials are pure aluminum and aluminum-silicon, aluminum-copper, aluminum-magnesium, aluminum-titanium-boron, aluminum-zirconium, aluminum-vanadium, and aluminum-scandium master alloys ;Perform preheating treatment on the weighed raw materials, the preheating temperature is 210°C, and the preheating time is 28min;

[0067] S2. Melting: add the preheated raw materials in step S1 into a resistance furnace and heat until me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com