Filtering material for water purification and air deodorization as well as preparation method and application of filtering material

A filter material and water purification technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve problems such as poor regeneration ability and limited purification ability, achieve excellent adsorption ability, and improve water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment discloses a filter material for water purification and air deodorization, comprising the following components by weight ratio:

[0047] 20 liters of volcanic ash, 140 liters of natural debris pumice, 30 liters of Portland cement, and 16 liters of water.

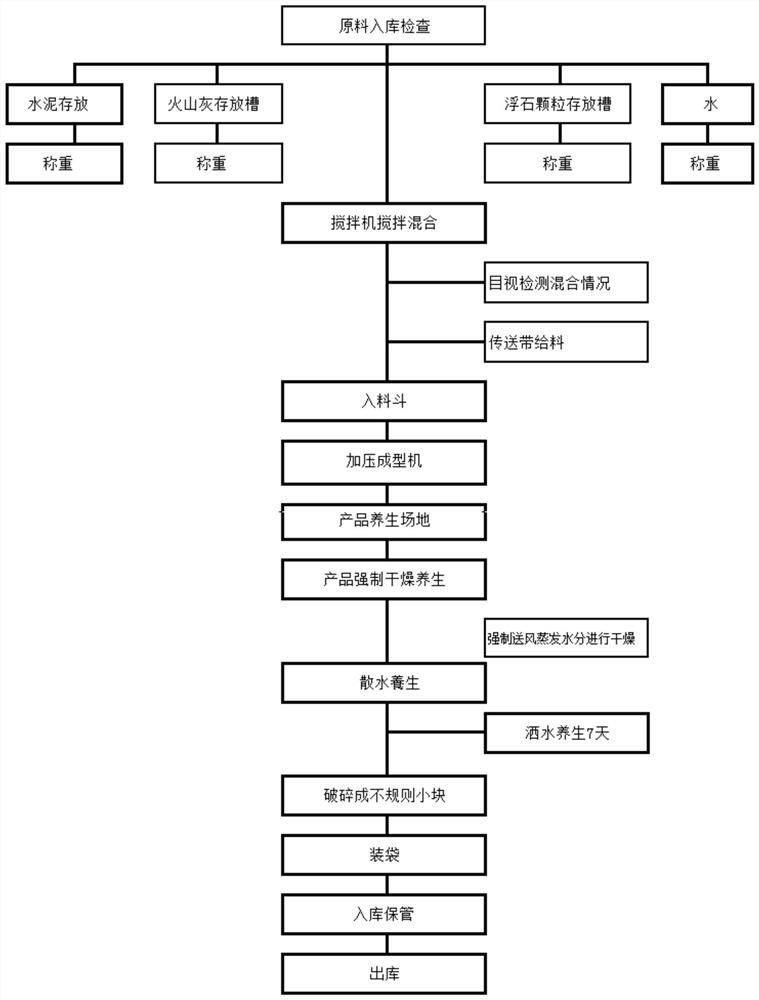

[0048] This embodiment is used for the preparation method of the filter material of water purification and air deodorization, as figure 1 shown, including the following steps:

[0049] Step 1. Mix volcanic ash, natural pumice and cement according to the ratio, slowly add water and stir for 3 minutes to obtain the mixture; hold and visually confirm the mixing state, if adjustment is required, add water to make fine adjustments and finally prepare the mixed material. According to the above ratio and quantity of mixing materials, more than 10 pieces of semi-finished products can be produced. In mass production, raw materials are input according to this ratio.

[0050] Step 2. Put the mixture into the si...

Embodiment 2

[0058] This embodiment discloses a filter material for water purification and air deodorization, comprising the following components by weight ratio:

[0059] 10 liters of volcanic ash, 30 liters of pumice in the form of natural debris, 15 liters of Portland cement, and 10 liters of water.

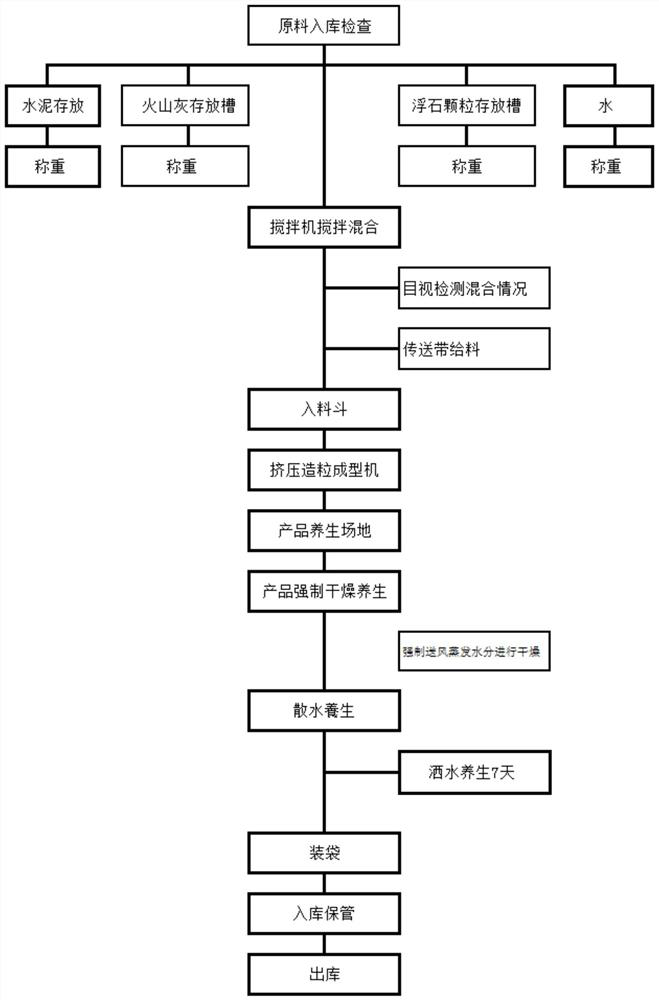

[0060] This embodiment is used for the preparation method of the filter material of water purification and air deodorization, as figure 2 shown, including the following steps:

[0061] Step 1. Mix volcanic ash, natural pumice and cement according to the ratio, add water and stir to obtain a mixture;

[0062] Step 2. Put the mixed material into the forming mold of the silo of the forming machine, pressurize and vibrate to form a plate shape or a square shape. After solidification and forming, the mold is demoulded and broken. Forced ventilation for a week under normal temperature conditions to force the moisture inside the material Evaporate and promote water and reaction to achieve vent...

Embodiment 3

[0070] This embodiment discloses a filter material for water purification and air deodorization, comprising the following components by weight ratio:

[0071] 10 liters of volcanic ash, 15 liters of pumice in the form of natural debris, 10 liters of Portland cement, and 16 liters of water.

[0072] This embodiment is used for the preparation method of the filter material of water purification and air deodorization, comprises the following steps:

[0073] Step 1. Mix volcanic ash, natural pumice and cement according to the ratio, add water and stir to obtain a mixture;

[0074] Step 2, put the well-mixed mixture into a granulator, extrude and granulate to form thin rod-shaped cylindrical particles, and the size of the thin rod-shaped cylindrical particles is 1 to 5 cm. In order to give full play to the function of the adhesive of cement, the formed plate is forced to ventilate at room temperature for a week, so that the internal moisture is volatilized.

[0075] Step 3, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com