Method for preparing lithium-doped and cobalt-loaded g-C3N4 photocatalyst

A photocatalyst, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as abandoning residual value, enhance photocatalytic performance, realize added value utilization, The effect of avoiding the use of high-purity metal salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

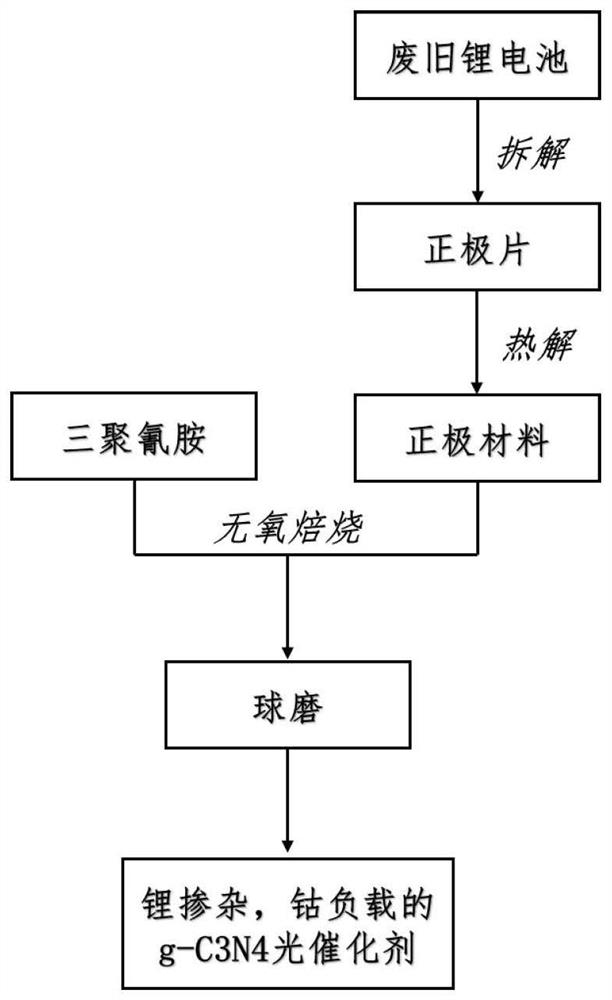

[0024] This embodiment provides a method for preparing lithium-doped, cobalt-supported g-C3N4 photocatalysts, such as figure 1 , including the following steps:

[0025] 1. Disassemble the waste lithium cobalt oxide battery to obtain the positive electrode sheet, and then vacuum pyrolyze the positive electrode sheet at 450°C for 30 minutes to remove the binder to obtain the lithium cobalt oxide positive electrode material;

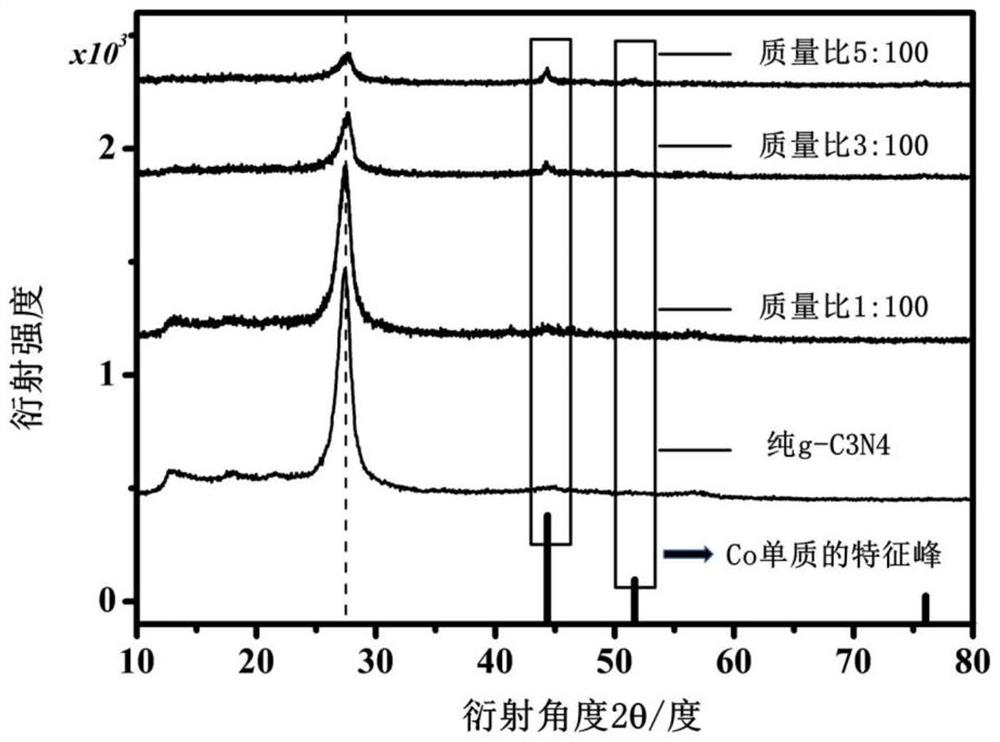

[0026] 2. Uniformly mix the obtained lithium cobalt oxide cathode material with melamine at a mass ratio of 3:100, and then perform anaerobic calcination. The nitrogen flow rate was controlled to 50ml / min, the heating rate was 5°C / min, the reaction temperature was 600°C, and the reaction time was 2h.

[0027] 3. The residue after the reaction was treated by ball milling to obtain the photocatalyst. The ball milling conditions were as follows: the rotation speed was 2000 rpm, and the reaction time was 1 h.

Embodiment 2

[0029] This embodiment provides a method for preparing lithium-doped, cobalt-supported g-C3N4 photocatalysts, such as figure 1 , including the following steps:

[0030] 1. Disassemble the waste lithium cobalt oxide battery to obtain the positive electrode sheet, and then vacuum pyrolyze the positive electrode sheet at 450°C for 30 minutes to remove the binder to obtain the lithium cobalt oxide positive electrode material.

[0031] 2. Mix the obtained lithium cobalt oxide cathode material with melamine uniformly at a ratio of 3:100, and then perform anaerobic calcination. The flow rate of argon gas is controlled to 100ml / min, the heating rate is 2°C / min, the reaction temperature is 550°C, and the reaction time is 2h.

[0032] 3. The residue after the reaction was treated by ball milling to obtain the photocatalyst. The ball milling conditions were as follows: the rotation speed was 2000 rpm, and the reaction time was 1 h.

Embodiment 3

[0034] This embodiment provides a method for preparing lithium-doped, cobalt-supported g-C3N4 photocatalysts, such as figure 1 , including the following steps:

[0035] 1. Disassemble the waste lithium cobalt oxide battery to obtain the positive electrode sheet, and then vacuum pyrolyze the positive electrode sheet at 450°C for 30 minutes to remove the binder to obtain the lithium cobalt oxide positive electrode material;

[0036] 2. Mix the obtained lithium cobalt oxide cathode material with melamine uniformly at a ratio of 3:100, and then perform anaerobic calcination. Control the argon flow rate to 100ml / min, the heating rate to 4°C / min, the reaction temperature to 650°C, and the reaction time to 0.5h;

[0037] 3. The residue after the reaction was treated by ball milling to obtain the photocatalyst. The ball milling conditions were as follows: the rotation speed was 2000 rpm, and the reaction time was 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com