High-temperature wear-resistant metal-based self-lubricating bearing with lubricating layer and preparation method thereof

A technology for lubricating bearings and lubricating layers, applied in the field of high-temperature wear-resistant metal-based self-lubricating bearings and its preparation, can solve problems such as the reduction of solid lubricant content, the impact on the service life of high-temperature-resistant bimetallic bearings, and bearing wear, and achieve self-lubricating Improvement of lubricating performance, reduction of friction coefficient and reduction of friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

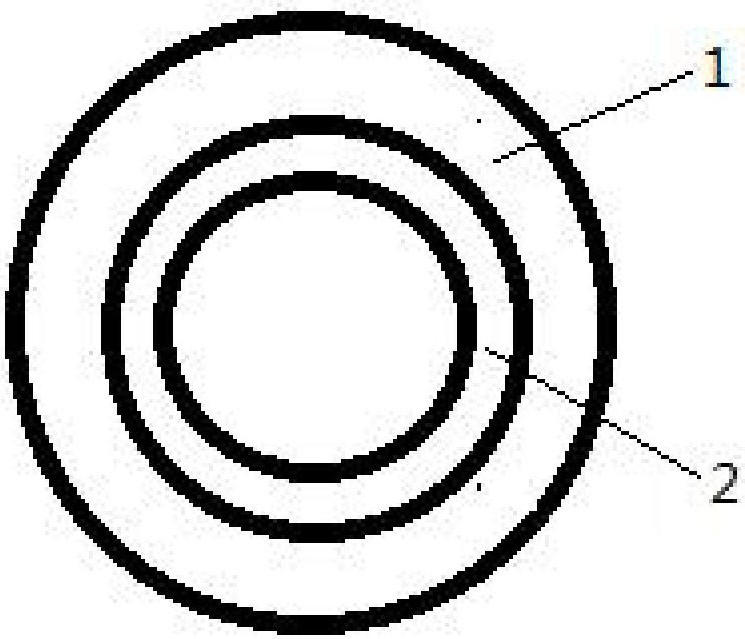

Image

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned high-temperature wear-resistant metal-based self-lubricating bearing with a lubricating layer comprises the following steps:

[0031] S1. Weigh the raw materials in the following mass percentages: Cu 75%~80%, C 0.3%~0.5%, Cr 14%~16%, S 0.2%~0.5%, Mo 0.4%~0.6%, Mn 5.1%~ 10%; Mix the weighed raw materials evenly and set aside;

[0032] Weigh Nb 4 C 3 , and added to liquid paraffin, dispersed evenly, to prepare lubricating liquid;

[0033] Process the C45 steel pipe with an outer diameter of 8cm and a thickness of 1cm into a seamless steel pipe sleeve with a height of 4cm;

[0034] S2. Put the raw material mixed in S1 into a high-hardness ring-shaped abrasive tool and press it at a pressure of 200-300 MPa. After demolding, a ring-shaped friction layer is obtained;

[0035] S3, putting the S2 annular friction layer into the S1 seamless steel sleeve to prepare a blank assembly, the gap between the annular friction layer and t...

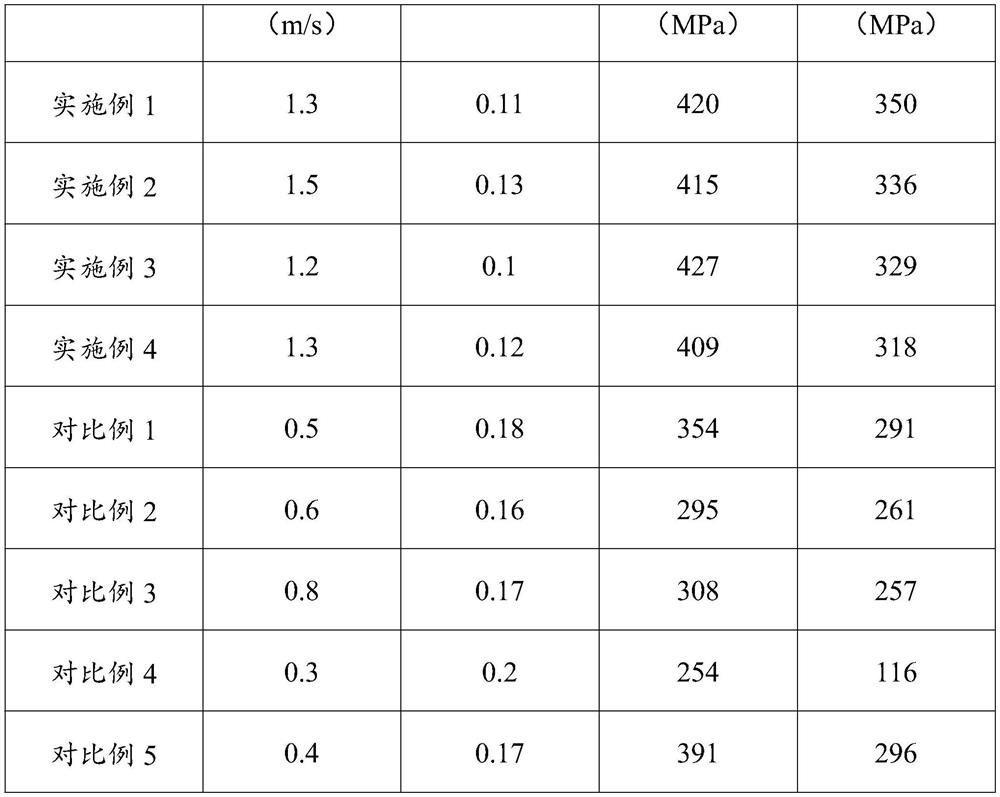

Embodiment 1

[0040] A high-temperature wear-resistant metal-based self-lubricating bearing with a lubricating layer, comprising a steel matrix and a friction layer located inside the matrix, the friction layer is made of the following components in mass percentages: Cu75%, C 0.5%, Cr 16%, S0.5%, Mo 0.6%, Mn 7.4%. The steel matrix and the friction layer are covered with a lubricating layer, and the lubricating layer is made of the following components: liquid paraffin, Nb 4 C 3 , and the Nb 4 C 3 The amount added is 10% of the liquid paraffin mass.

[0041] The preparation method of the above-mentioned high-temperature wear-resistant metal-based self-lubricating bearing with a lubricating layer comprises the following steps:

[0042] S1. Weigh the raw materials in the following mass percentages: Cu75%, C 0.5%, Cr 16%, S 0.5%, Mo0.6%, Mn 7.4%; mix the weighed raw materials evenly and set aside; weigh Nb 4 C 3 , and added to liquid paraffin, dispersed evenly, to prepare lubricating liqu...

Embodiment 2

[0049] A high-temperature wear-resistant metal-based self-lubricating bearing with a lubricating layer, comprising a steel matrix and a friction layer located inside the matrix, the friction layer is made of the following components in mass percentages: Cu 80%, C 0.3%, Cr 14%, S0.2%, Mo 0.4%, Mn 5.1%. The steel matrix and the friction layer are covered with a lubricating layer, and the lubricating layer is made of the following components: liquid paraffin, Nb 4 C 3 , and the Nb 4 C 3 The amount added is 20% of the liquid paraffin quality.

[0050] The preparation method of the above-mentioned high-temperature wear-resistant metal-based self-lubricating bearing with a lubricating layer comprises the following steps:

[0051] S1. Weigh the raw materials in the following mass percentages: Cu 80%, C 0.3%, Cr 14%, S 0.2%, Mo0.4%, Mn 5.1%; mix the weighed raw materials evenly, and set aside; weigh Nb 4 C 3 , and added to liquid paraffin, dispersed evenly, to prepare lubricatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com