Method for detecting content of caprolactone in acrylic resin

A technology of acrylic resin and detection method, which is applied in the field of detection and analysis, can solve the problem that the detection of caprolactone content does not have any national standards and analysis methods, and affects the quality of acrylic resin products, so as to reduce costs, improve detection accuracy, and improve detection. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

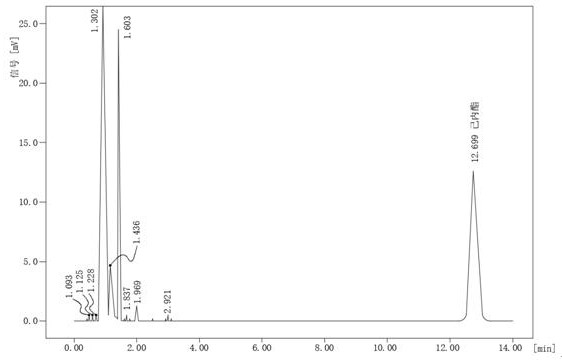

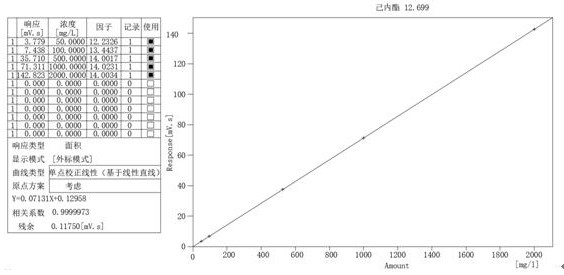

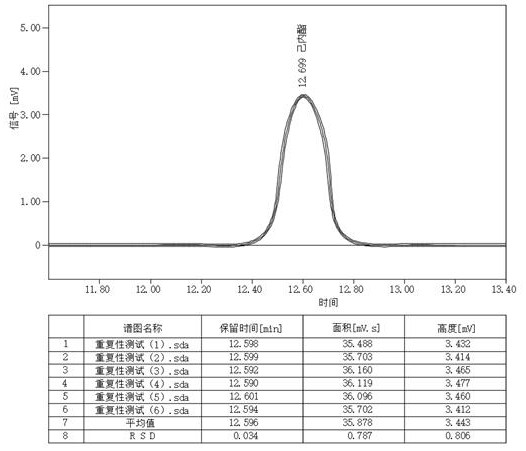

[0029] see Figure 1~3 , in the embodiment of the present invention, the detection method of caprolactone content in acrylic resin, comprises the following steps:

[0030] S1. Sample preparation: the solvent selected by the gas chromatograph is chromatographic grade pure ethyl acetate, and the column material of the gas chromatograph is a quartz capillary column;

[0031] S2. Setting of chromatographic conditions: the column temperature of the gas chromatograph is set to 90°C (5min), 10°C / min, 280°C (10min), the temperature of the injector is 280°C, the temperature of the detector is 280°C, and the carrier gas is nitrogen The flow rate is 30mL / min, the air flow rate is 300 mL / min, the hydrogen flow rate is 30mL / min, and the injection volume is 0.5mL;

[0032] S3, detection operation: start the gas chromatograph, then mix the acrylic resin liquid sample and ethyl acetate evenly, and perform data analysis and processing, and then calculate the content of caprolactone in the acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com