High-strength aluminum alloy powder, application of high-strength aluminum alloy powder in 3D printing and 3D printing method of high-strength aluminum alloy powder

A 3D printing and aluminum alloy technology, applied in the field of 3D printing, can solve the problems of restricting wide application and achieve the effect of inhibiting the formation and expansion of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

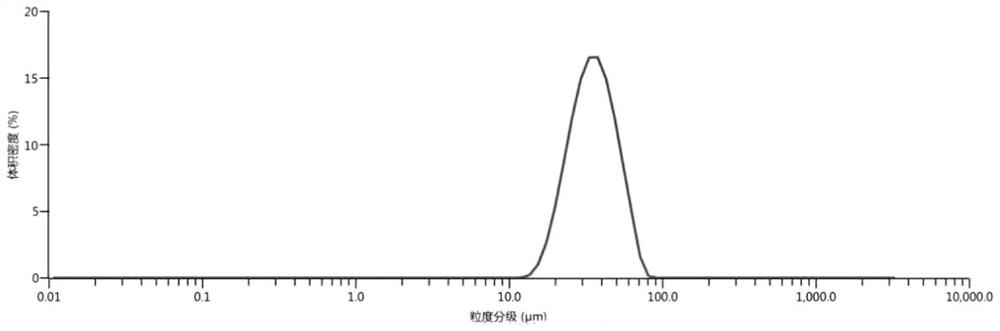

[0029] Example 1 prepared a special Al-Mn-Mg-Sc-Zr aluminum alloy powder for 3D printing. In terms of mass percentage, the composition content of elements in the aluminum alloy microparticles is: Mn: 4.95wt%; Mg Sc: 0.73wt%; Zr: 0.22wt%; Si: 0.03wt%; Fe: 0.05wt%, and the rest is Al. figure 1 It is a schematic diagram of the particle size distribution of the high-strength aluminum alloy powder prepared according to the formula of Example 1 of the present invention. Such as figure 1 As shown, the particle size distribution of the aluminum alloy powder presents a typical normal distribution, and the particle size is 15-63 microns, which meets the technical requirements of SLM printing.

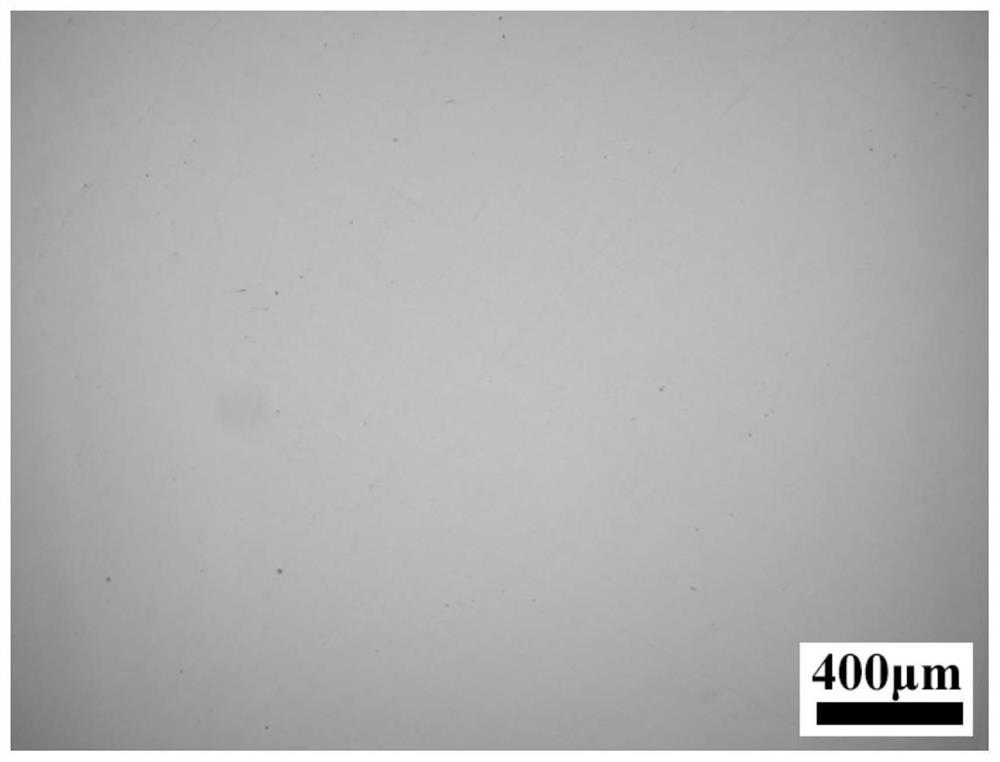

[0030] Using the above-mentioned aluminum alloy powder for 3D printing work, firstly, before printing, put the above-mentioned aluminum alloy powder in a drying oven for drying treatment, and keep it warm at 80°C for 6h. Before printing, argon gas is passed into the printing chamber to control ...

Embodiment 2

[0035] Example 2 prepared a special Al-Mn-Mg-Sc-Zr aluminum alloy powder for 3D printing. In terms of mass percentage, the composition content of the elements in the aluminum alloy microparticles is: Mn: 4.22wt%; Mg Sc: 0.68wt%; Zr: 0.28wt%; Si: 0.06wt%; Fe: 0.07wt%, and the rest is Al.

[0036] Using the above-mentioned aluminum alloy powder for 3D printing work, firstly, before printing, put the above-mentioned aluminum alloy powder in a drying oven for drying treatment, and keep it warm at 80°C for 6h. Before printing, argon gas is passed into the printing chamber to control the oxygen content below 200ppm, and at the same time, the temperature of the substrate is heated to 90°C.

[0037] Next, the 3D printing work is carried out, and the following printing parameters are used: the laser power is 370W; the scanning speed is 1100mm / s; the scanning distance is 0.13mm; the scanning layer thickness is 0.03mm.

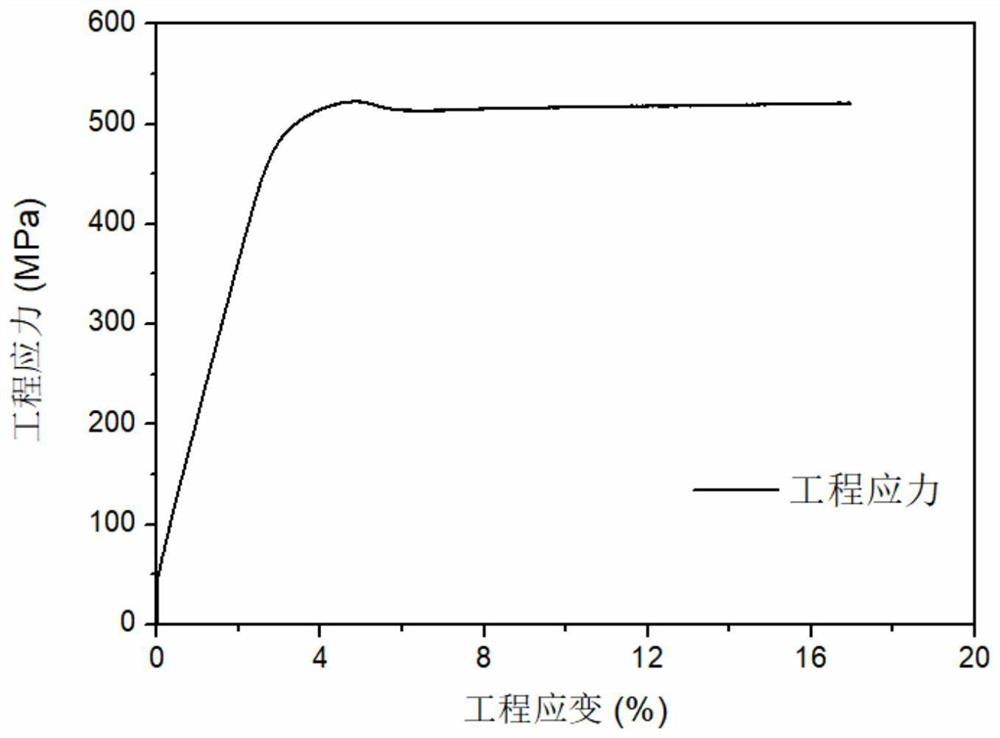

[0038] After printing, the mechanical properties of the printed pr...

Embodiment 3

[0042] Example 3 prepared a special Al-Mn-Mg-Sc-Zr aluminum alloy powder for 3D printing. In terms of mass percentage, the composition content of the elements in the aluminum alloy microparticles is: Mn: 4.89wt%; Mg Sc: 0.71wt%; Zr: 0.3wt%; Si: 0.05wt%; Fe: 0.03wt%, and the rest is Al.

[0043] Using the above-mentioned aluminum alloy powder for 3D printing work, firstly, before printing, put the above-mentioned aluminum alloy powder in a drying oven for drying treatment, and keep it warm at 80°C for 6h. Before printing, argon gas is passed into the printing chamber to control the oxygen content below 200ppm, and at the same time, the temperature of the substrate is heated to 90°C.

[0044] Next, the 3D printing work is carried out, and the following printing parameters are used: the laser power is 370W; the scanning speed is 1100mm / s; the scanning distance is 0.13mm; the scanning layer thickness is 0.03mm.

[0045] After printing, the mechanical properties of the printed produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com