High-entropy alloy powder and preparation method and application of laser cladding layer

A high-entropy alloy and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems of low service life, improve corrosion resistance, reduce diffusion and redistribution rate, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0032] 1. Calculate the ratio of FeCoCrNiMnAl high-entropy alloy powder according to the molar ratio: Fe is 16.67mol%, Co is 16.67mol%, Cr is 16.67mol%, Ni is 16.67mol%, Mn is 16.66mol%, Al is 16.66mol% , the total molar ratio is 100%, and electronic scales are used to weigh the powders of various elements.

[0033] 2. Pour into a mortar and grind in the mortar for half an hour to mix well.

[0034] 3. Mix the prepared laser cladding powder, 92% and 8% ethanol to form a paste or paste, and then coat it on the surface of H13 steel with a preset layer thickness of 1mm. After air-drying, perform laser cladding.

[0035] 4. Laser cladding process parameters are: laser power 1550KW, spot diameter 2.5mm, scanning speed 5mm / s, defocus distance 10mm, protective gas argon, gas flow 25L / min.

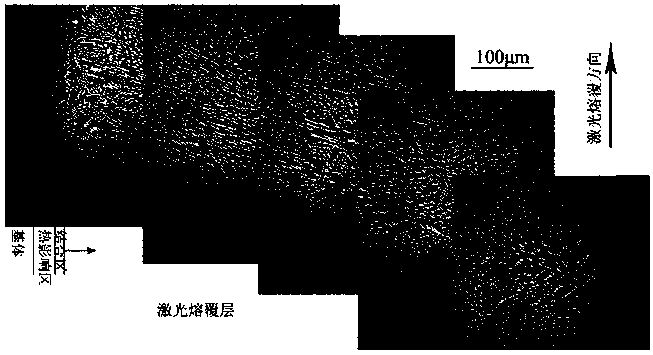

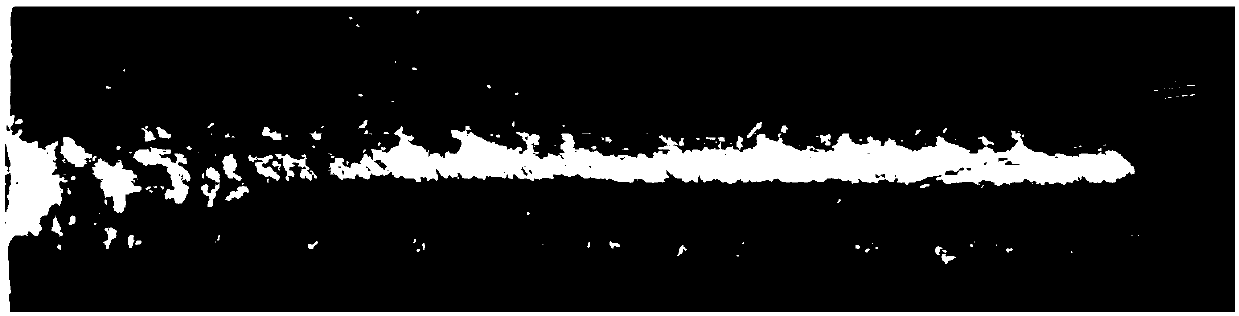

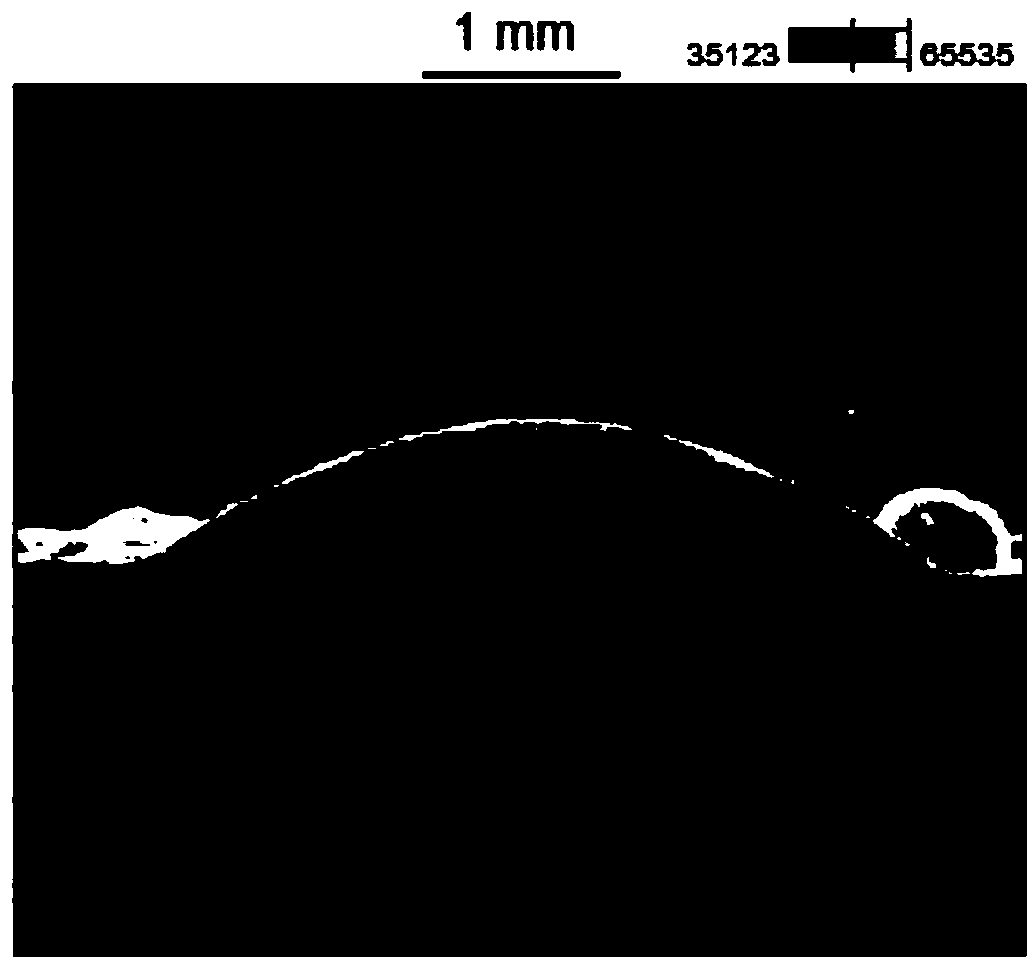

[0036] 5. After laser cladding, aqua regia was used to corrode, and the metallographic photos of the cladding layer were obtained.

[0037] The microhardness of the cladding layer was measured b...

Embodiment example 2

[0040] 1. Mix the prepared laser cladding powder, 95% and 5% ethanol into a paste or paste, and coat it on the surface of H13 steel with a pre-set layer thickness of 1.2mm. After air-drying, perform laser cladding.

[0041] 2. Laser cladding process parameters are: laser power 1600KW, spot diameter 3.0mm, scanning speed 6mm / s, defocus distance 10mm, protective gas helium, gas flow rate 20L / min.

[0042] 3. Use the same performance test, the results are shown in the table below.

Embodiment example 3

[0044]1. Mix the prepared laser cladding powder, 94% and 6% ethanol into a paste or paste, and coat it on the surface of H13 steel with a pre-set layer thickness of 0.8mm. After air drying, perform laser cladding.

[0045] 2. Laser cladding process parameters are: laser power 1400KW, spot diameter 3.5mm, scanning speed 7mm / s, defocusing distance 10mm, protective gas argon, gas flow rate 22L / min.

[0046] 3. Use the same performance test, the results are shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com