Performance gain structure of transmission coil and design method thereof

A transmission coil, performance technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, circuit devices, etc., can solve the problem of large area of transmission coil contacting PCB substrate, increase the transmission efficiency of substrate coil, and compress enameled wire Insulation skin and other issues, to achieve the effect of flexible design, reduce tangent loss, and improve heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

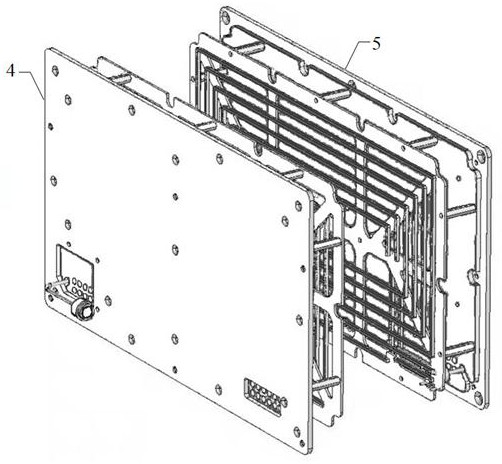

[0036] A performance gain structure for a transmission coil such as figure 1 As shown, the receiving module 5 has the same structure as the transmitting module 4 and is arranged symmetrically.

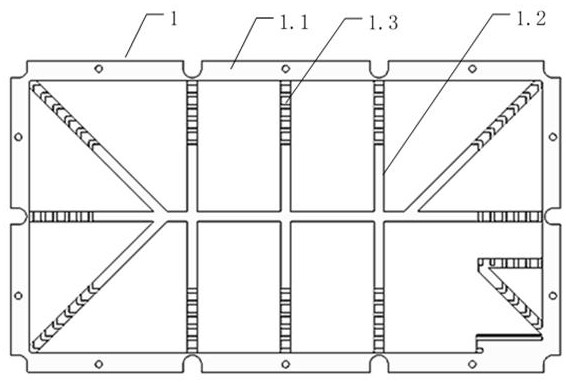

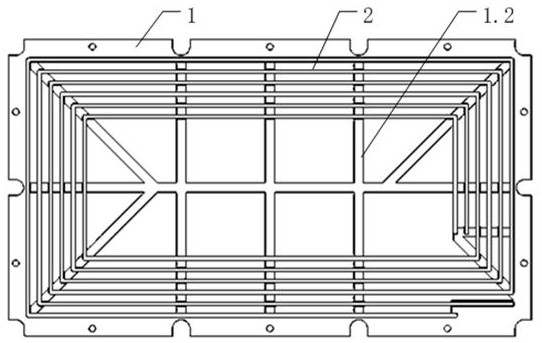

[0037] like Figure 2-4 As shown, the receiving module 5 includes an insulating substrate frame 1, on which the coil 2 is wound, and the substrate frame 1 includes a frame 1.1 hollowed out inside, and a plurality of ribs 1.2 for supporting the coil 2 are arranged inside the frame 1.1. The ribs 1.2 are perpendicular to the winding direction of the coil 2. The position where the coil 2 contacts the substrate skeleton 1 is provided with a fixed structure 1.3. The side of the substrate skeleton 1 far away from the coil 2 is equipped with a magnetic partition 3, and the magnetic partition 3 is evenly provided with multiple Holes 3.1.

[0038] The magnetic separator 3 is parallel to the coil 2 to enhance the gain of the magnetic field in the transmission direction, and the parallelism of t...

Embodiment 2

[0050] A method for designing a performance gain structure of a transmission coil, specifically performed according to the following steps:

[0051] Step 1: Engraving the outline corresponding to coil 2 on the copper skin of the existing PCB substrate (or copper clad laminate);

[0052] Step 2: Keep the ribs and bones of the PCB substrate to support the coil 2, and hollow out the rest of the area;

[0053] Step 3: The copper skin of the ribs is used as the supporting solder joint of the coil 2;

[0054] Step 4: Fully immerse silver on the copper surface to prevent copper oxidation and improve conductivity.

[0055] The present invention has the following advantages:

[0056] 1. Improve the heat dissipation performance of the coil while improving the coupling transmission efficiency of the coil; according to the simulation results of the embodiment of the present invention and the existing unprocessed circuit board comparison, the substrate skeleton 1 of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com