Chip removal type linear sliding bearing and precision casting method and machine casting method thereof

A linear sliding and bearing technology, applied in the mechanical field, can solve the problems such as the difficulty of smooth running of the sliding shaft, the shortened service life of the linear bearing, the easy displacement of the cage structure or the inability to vibrate the sliding shaft, etc., so as to improve the service life and reduce the friction force. , to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

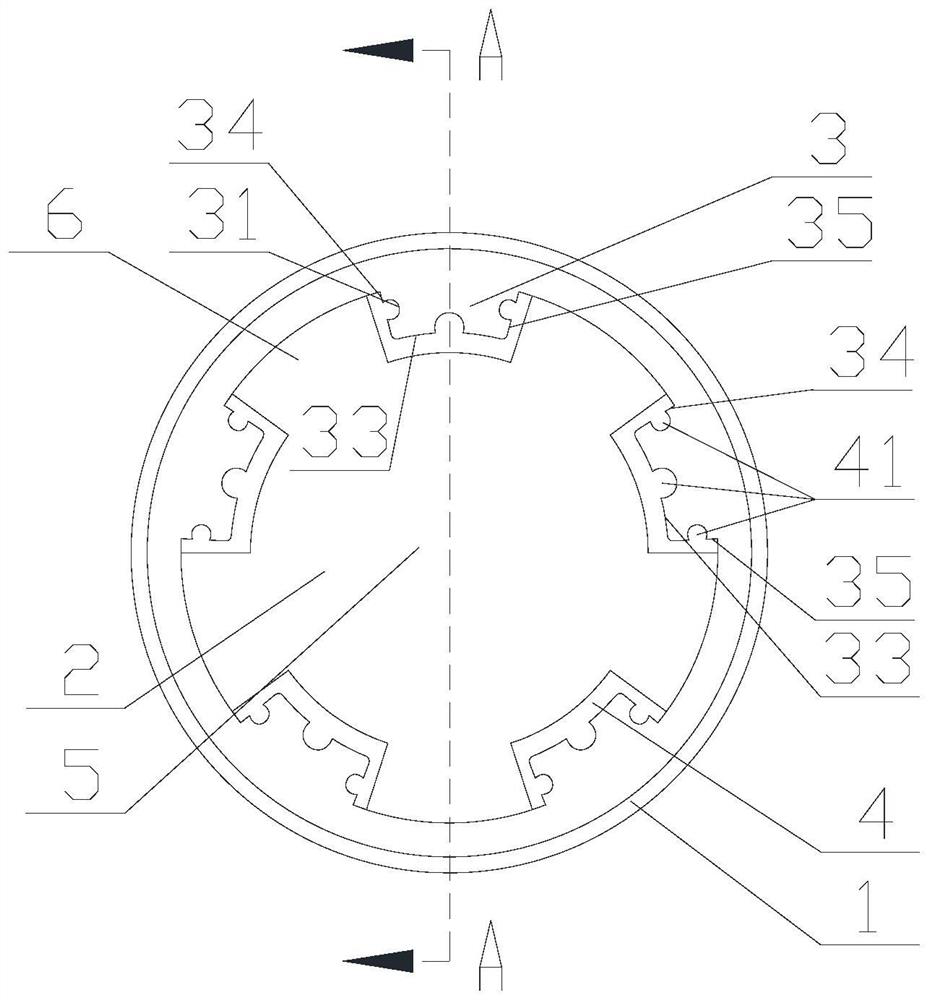

[0052] see Figure 1-Figure 3 , this embodiment provides a chip removal type linear sliding bearing, including:

[0053] A bearing sleeve 1 with a channel 2, and the channel 2 runs through both ends of the bearing sleeve 1;

[0054] The support bar 3 is fixed on the side wall of the channel 2;

[0055] The polymer structure 4 wraps the support bar 3 and connects with the support bar 3;

[0056] A plurality of polymer structures 4 surround the shaft channel 5 in the channel 2, and two adjacent polymer structures 4 and the side walls of the channel 2 surround and form a longitudinal chip removal channel 6; wherein, several support bars 3 surround the shaft channel 5 The axes are arranged equidistantly.

[0057] The working principle of the above technical solution is: the sliding shaft (not shown in the figure) is inserted into the shaft channel 5 from one end of the bearing sleeve 1, and passes through the other end of the bearing sleeve 1; The molecular structure 4 makes t...

Embodiment 2

[0086] see Figure 1-Figure 4 , this embodiment provides a precision casting method for a chip removal type linear sliding bearing, which is used to manufacture a chip removal type linear sliding bearing, including:

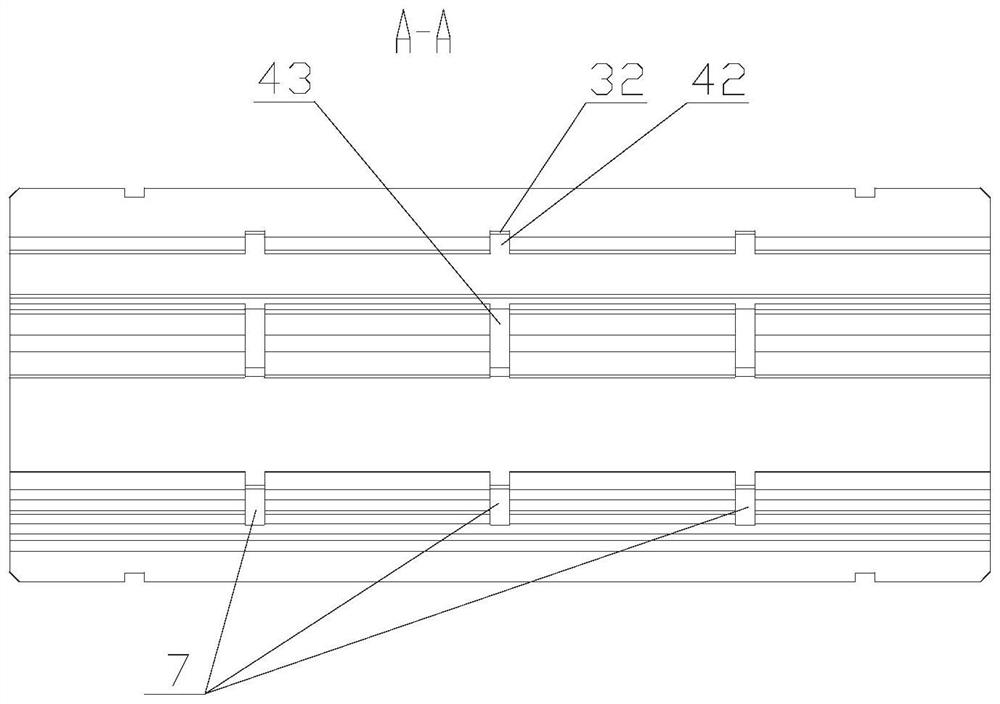

[0087] PS1: Make a set of wax patterns corresponding to the bearing sleeve 1 and a strip wax pattern corresponding to the support strip 3, and connect the strip wax patterns in the channels of the set of wax patterns to form a precision casting assembly; wherein, the strips The wax fine casting mold has the transverse wax strip corresponding to the transverse groove, the longitudinal wax strip corresponding to the longitudinal groove, and the groove wax strip corresponding to the transverse groove 43;

[0088] PS2: Coating at least one shell layer on the precision casting assembly to obtain a precision casting shell, and performing thermal processing on the precision casting shell to obtain a precision casting mold;

[0089] PS3: casting the prefabricated alloy ...

Embodiment 3

[0128] see Figure 1-Figure 3 as well as Figure 5 , the present embodiment provides a machine casting method for a chip removal type linear sliding bearing, which is used to manufacture a chip removal type linear sliding bearing, including:

[0129] MS1: making at least one wax pattern, and combining the wax patterns to form a machine-cast assembly;

[0130] MS2: Coating at least one shell layer on the machine-cast assembly to obtain a machine-cast shell, and performing thermal processing on the machine-cast shell to obtain a machine-cast mold;

[0131] MS3: casting the prefabricated alloy liquid into the machine-casting mold, and forming the alloy liquid in the machine-casting mold to obtain a rough machining sleeve;

[0132] MS4: Machining the transverse groove 32 and the longitudinal groove 31 in the rough machining sleeve to obtain the bearing sleeve 1 with the support bar 3;

[0133] MS5: Inject polymer material into the bearing sleeve 1 to perform injection molding o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com