Electron extraction type freewheel diode device and preparation method thereof

A freewheeling diode and device technology, which is applied to the structure of an electron extraction type freewheeling diode device and the field of its preparation, can solve problems such as the limitation of the adjustment range of hole injection efficiency, and achieves reduction of manufacturing cost, reduction of process difficulty, and increase of adjustment. Amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

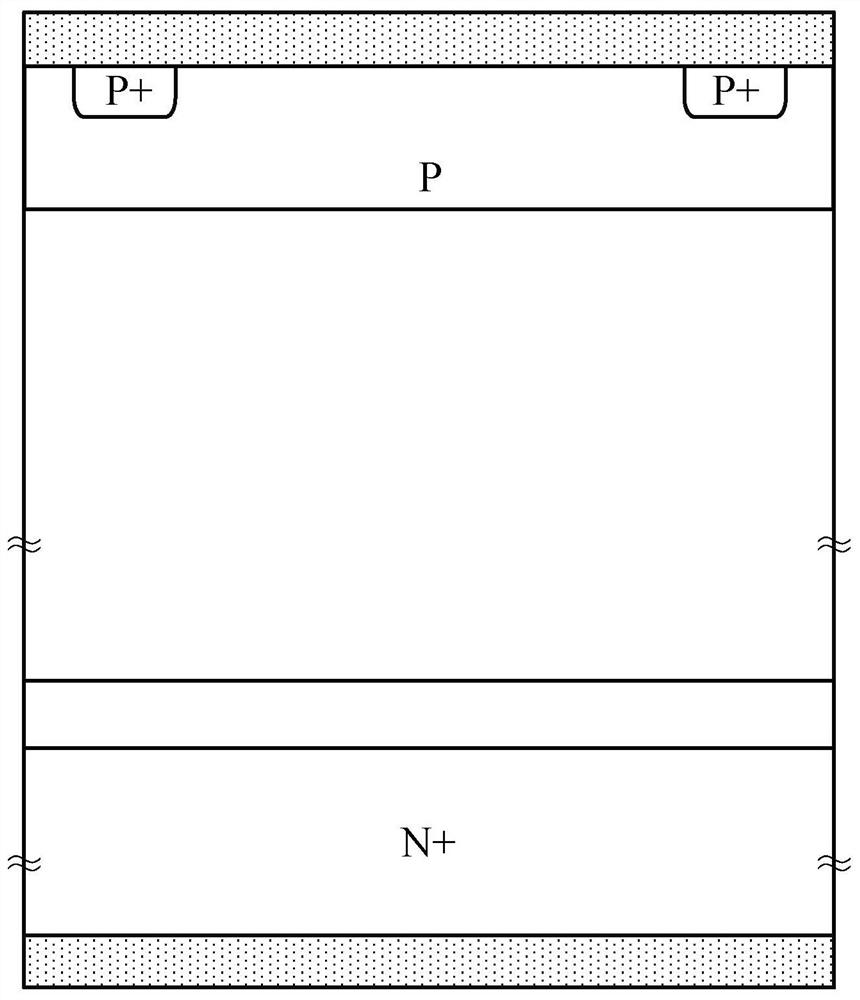

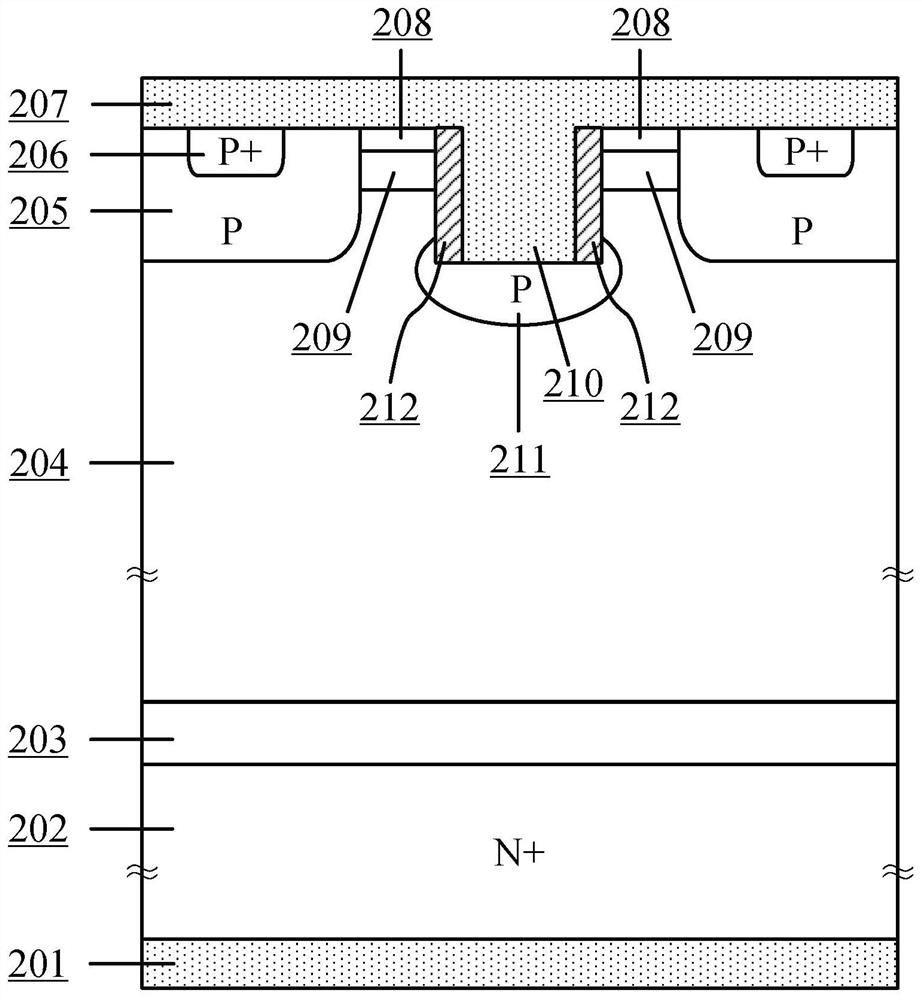

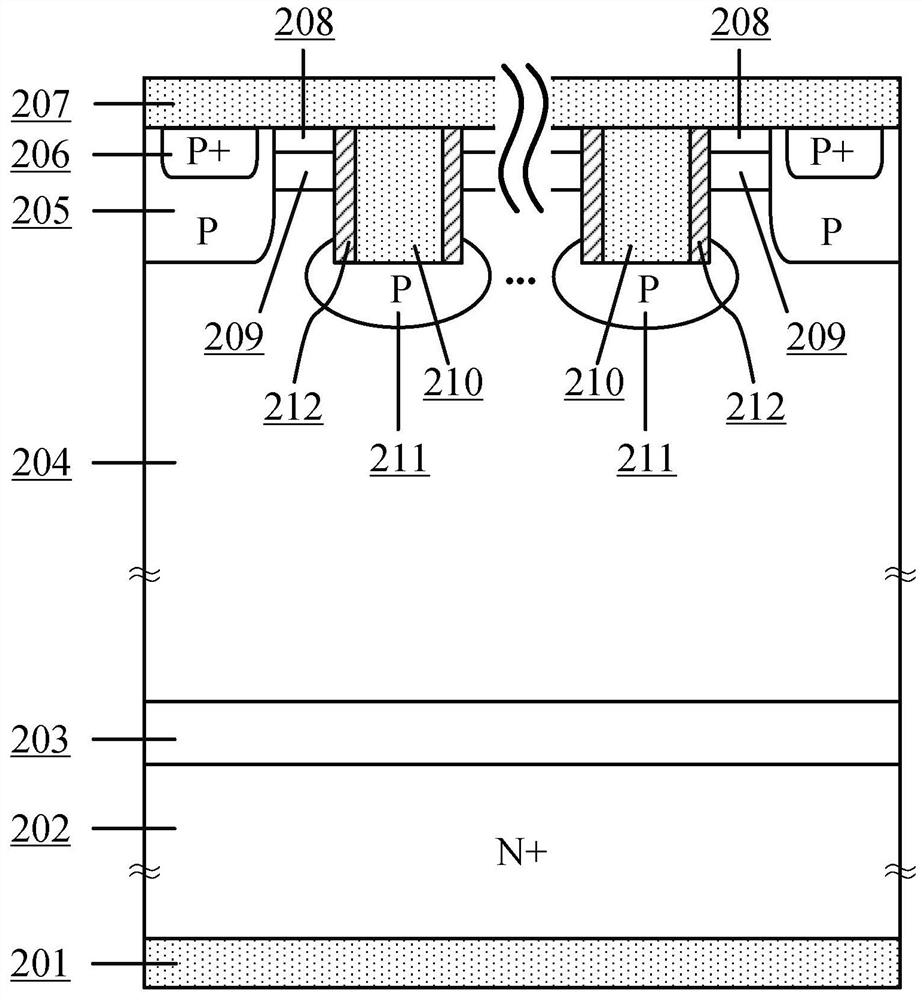

[0044] figure 2 It is a cross-sectional schematic view of the device structure of the vertical trench electron extraction type freewheeling diode according to the first embodiment of the present invention. The device structure has: a cathode electrode 201 at the bottom, a heavily doped N-type semiconductor substrate 202 and an N-type buffer layer 203 above the cathode electrode 201, and an N-type drift region 204 is located on the N-type buffer layer 203; The upper surface of the N-type drift region 204 has a P-type planar anode region 205, a lightly doped P-type base region 209, and a P-type trench anode region 211. The upper surface of the P-type planar anode region 205 has a partially heavily doped P-type ohmic region. Contact region 206; the upper surface of the lightly doped P-type base region 209 has a heavily doped N-type emitter region 208; the P-type planar anode region 205 and the heavily doped N-type emitter region The region 209 is adjacent, and the P-type planar...

Embodiment 2

[0058] Figure 4 is an enlarged cross-sectional view of a device according to a second embodiment of the present invention. compared to figure 2 The difference between the device structure in the first embodiment and the device structure in the second embodiment is that a slope trench structure is used. The shape of the slope trench region 310 is an inverted trapezoid, the angle between the side wall and the vertical direction can be 60-90°, and the side wall is completely surrounded by the heavily doped N-type emitter region, forming an ohmic contact with the anode electrode. When the position of the punch-through NPN transistor is adjusted from adjacent to the groove gate to the side wall of the slope groove gate, the conductive area of the anode will be effectively increased, which is beneficial to reduce the conduction voltage drop and improve the forward anti-surge current capability of the device. With the increase of the slot gate density, the electron extraction a...

Embodiment 3

[0070] Figure 6 is an enlarged cross-sectional view of the device according to the third embodiment of the present invention. compared to figure 2 The difference between the device structure shown in the first embodiment and the device structure in the third embodiment is that the area of the anode P-type region is increased. The anode electrode 407 is simultaneously connected to the side wall of the vertical groove area 410 and the P-type groove anode area 411. The P-type groove anode area 411 surrounds the left and right side walls and the bottom of the vertical groove area 410. The anode electrode 407 and The P-type trench anode region 411 forms a Schottky contact. This structure increases the conductive area of the P-type region, helps to control the anode hole injection efficiency, and also narrows the JFET conductive channel, enhances its shielding effect on high electric fields, and helps reduce leakage current at high temperatures .

[0071] in the same cell,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com