Process method and equipment for preparing activated sludge-based granular biochar based on one-step method

A technology of activated sludge and biochar, applied in the field of sludge recycling, can solve the problems of small overall application range, high product impurity content, reduced dehydration efficiency, etc., to achieve improved deodorization effect, fast preparation efficiency, simple and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

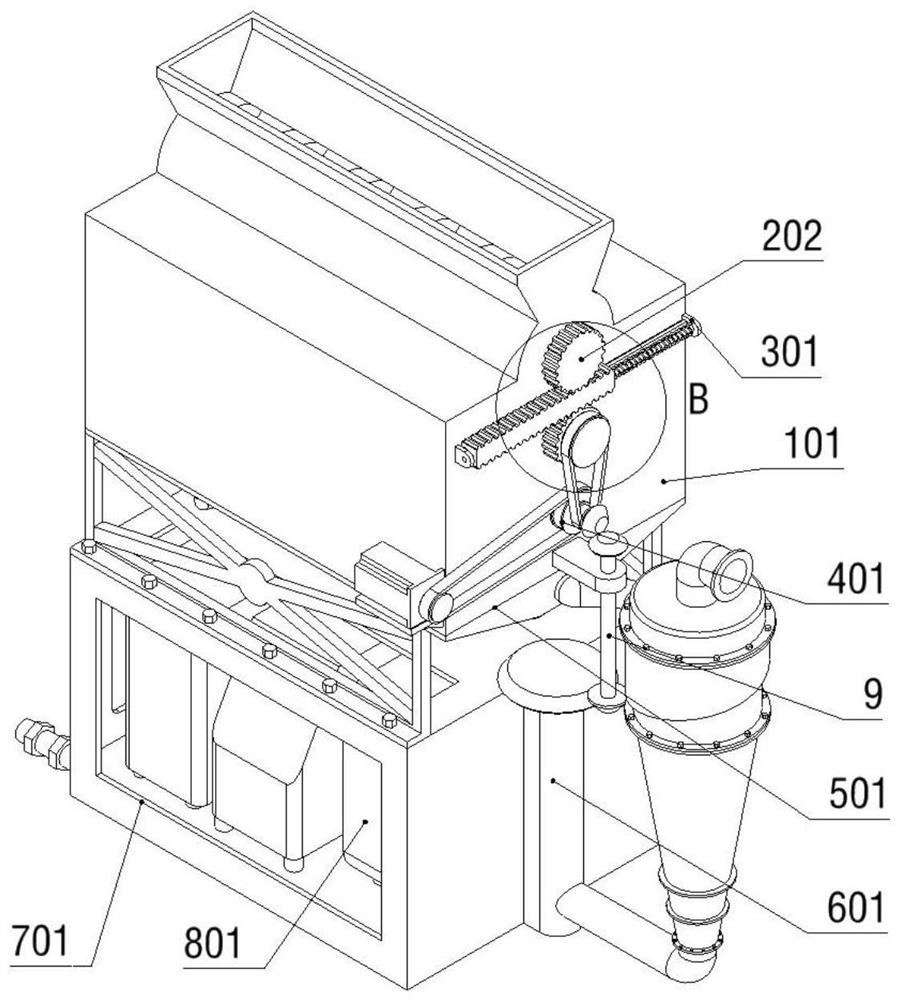

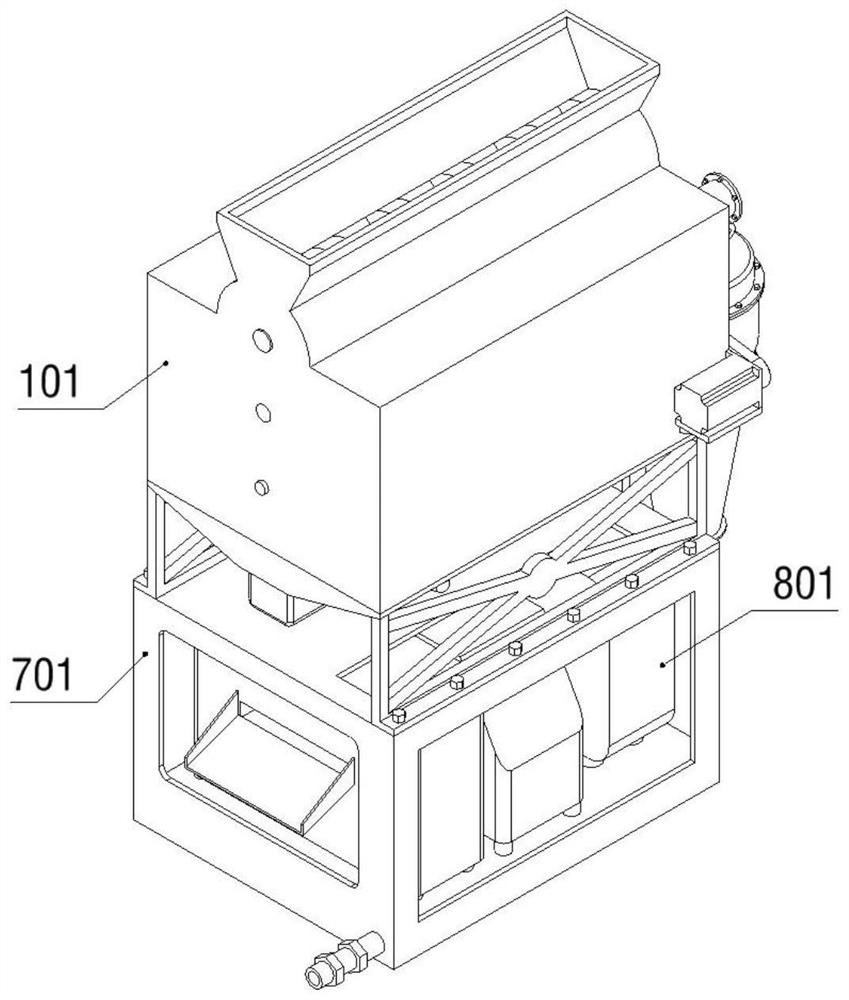

[0045] Please refer to Figure 1 to 15 :

[0046] The present invention proposes an apparatus for preparing the active sludge particles based on a one-step method, including a feed apparatus 1; a separated lower material portion 2 is attached to the feed apparatus 1; a reciprocating drive portion 3 is fixed to the feed device 1; The feed device 1 is mounted on the fitting device 4; the feed device 1 is fixedly connected to the deodorant inorganic separation portion 5; the deodorant-inorganic separation portion 5 is mounted with a dehydration device 6; the dewatering device 6 is fixedly connected to the convection mount Section 7; The flow mounting portion 7 is fixed to the bottom of the deodorant and inorganic separation portion 5; the heat transfer mounting portion 7 is mounted in the mounting unit 8; the feed device 1 includes: the feed tank 101, the feed tank 101 side is fixed by the stent The discharge motor 1011 is connected; a pulley is provided with a pulley 102, and the low...

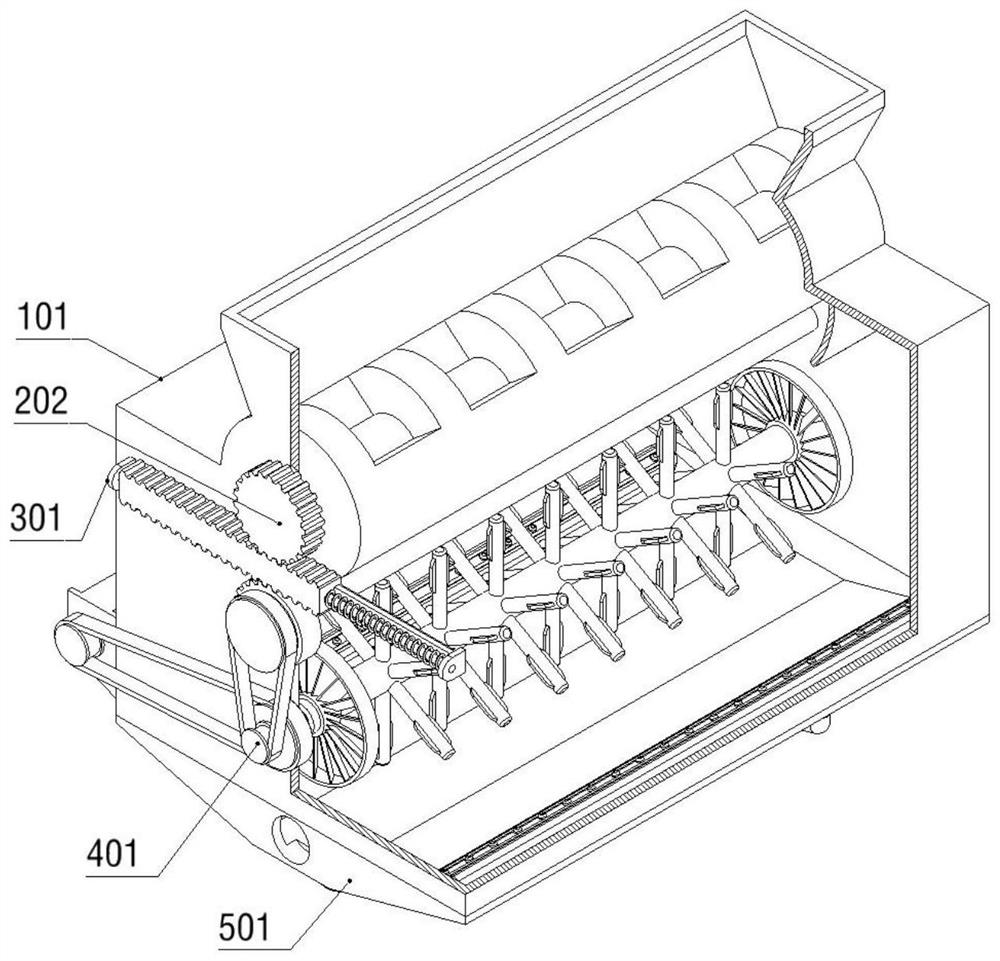

Embodiment 2

[0050] In addition, if Figure 7 , 89, 15, the separation of the lower material portion 2 includes: the feed roller 201, the tetrane roll 201 is rotatably coupled to the feed port 103; a tank groove 2011 is opened on the taking roller 201; the outer side of the taking roller 201 The inner side of the feed port 103 is attached to the inner side of the feed port 103, and the rotating taking gear 202 is fixedly attached to the side axis end of the taking roller 201; the reciprocating drive unit 3 includes a rack slide strip 301, a rack slide strip 301 fixed connection On the side of the feed tank 101; reciprocating drive rack 302, the reciprocating drive rack 302 is slidably coupled to the rack sliding strip 301; the reciprocating drive rack 302 is respectively provided with meshing teeth; the reciprocating drive rack 302 is respectively engaged. The molar gear 104 is fixed to the rotating taking gear 202; the sliding connection shaft 303 is fixed to the rack sliding strip 301; the sl...

Embodiment 3

[0052] In addition, if Figure 12 , 13 , The dewatering device 6 includes: a mounting shell 601, a mounting shell 601 having a swirl holder 6011; the mounting housing 601 is connected to the sludge outlet 5042 by a swirler connection tube 601 The twezy mounting shell 601 is provided with a guide mesh 6012; the top of the twinkle mounting case 601 is provided with a twinkle discharge port 6013; driving the twin 602, drive the twinkling 602 to rotate the attachment of the shell 601; The top shaft end of the dragon 602 passes through the strap mounting shell 601; the drum is driven on the drum 602, and the molten bevel gear 603 is fixed to the drive strap 602; the flow of the guide mounting portion includes: Diversion mounting box 701, the convection mounting tank 701 side is provided with water hole 7011; the top bracket of the flow mounting box 701 is fixed to the bottom of the deodorant base 501; the convection mounting tank 701 is fixedly connected to the mounting shell 601; The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com