Superfine titanium alloy powder, preparation method thereof and vertical hydrogenation and dehydrogenation furnace

A technology for hydrogenation and dehydrogenation and titanium alloys, which is used in metal processing equipment, transportation and packaging, etc., can solve the problems of incomplete dehydrogenation and deoxidation, high impurity content, and complicated operation, so as to shorten production time, reduce impurity content, and speed up production. The effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

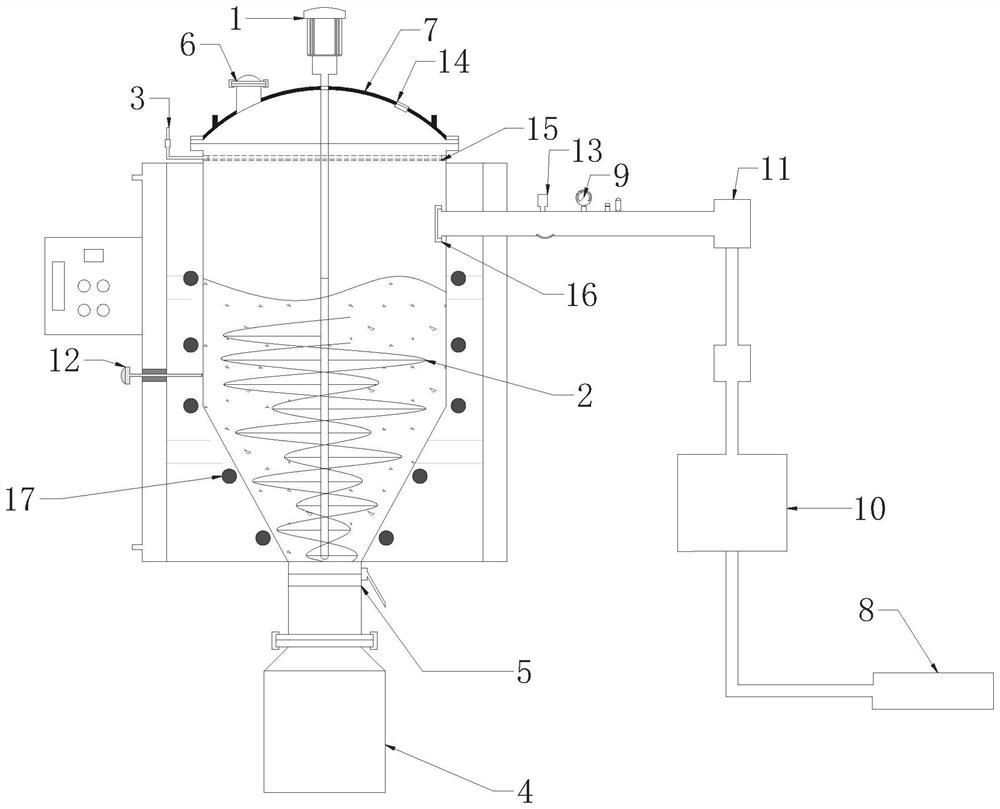

[0030] In yet another aspect, the present invention also provides a method for preparing ultrafine titanium alloy powder, which includes: cleaning, drying, and deoxidizing the raw materials, adding them to a hydrodehydrogenation furnace; Filling with hydrogen gas, after hydrogenation reaction occurs, the hydrogenated material is obtained; the hydrogenated material is ball milled to obtain the ball milled material; the ball milled material is put into the hydrogenation dehydrogenation furnace, after the dehydrogenation reaction occurs, the dehydrogenated material is obtained , which is ultrafine titanium alloy powder.

[0031] Specifically, the ultra-fine titanium alloy powder in the present invention is mainly TC4 titanium alloy, which can be TC4 turning chips, turning scraps, coarse powder (150-250 μm), etc., and the element composition meets the GB / T 4698 national standard It is required that the prepared ultrafine titanium powder has an oxygen content of no more than 0.15wt...

Embodiment 1

[0051] Cleaning of raw materials: put TC4 turning chips, turning materials, etc. into an ultrasonic cleaning machine with a certain amount of alcohol for cleaning, to remove impurities and oil on the surface of raw materials, and clean 50Kg of raw materials each time.

[0052] Drying: Put the cleaned raw materials into an oven for drying for 2 hours; the drying temperature is 130°C to prevent the raw materials from being oxidized and oxygenated.

[0053] Preparation before hydrogenation: Check whether the water, electricity and gas of the vertical hydrogenation dehydrogenation furnace are operating normally, install the receiving tank, tighten the vacuum caliper, close the high temperature valve, add the dried raw materials into the furnace through the feeding bin, and close the furnace cover.

[0054] Vacuuming: Turn on the low-vacuum pump group, open the low-vacuum valve, evacuate to below 10Pa, then fill in high-purity argon (5N) until the vacuum gauge is -0.05MPa, repeat t...

Embodiment 2

[0064] Cleaning of raw materials: put TC4 turning chips, turning materials, etc. into an ultrasonic cleaning machine with a certain amount of alcohol for cleaning, to remove impurities and oil on the surface of raw materials, and clean 50Kg of raw materials each time.

[0065] Drying: Put the cleaned raw materials into an oven for drying for 2 hours; the drying temperature is 110°C to prevent the raw materials from being oxidized and oxygenated.

[0066] Preparation before hydrogenation: Check whether the water, electricity and gas of the vertical hydrogenation dehydrogenation furnace are operating normally, install the receiving tank, tighten the vacuum caliper, close the high temperature valve, add the dried raw materials into the furnace through the feeding bin, and close the furnace cover.

[0067] Vacuuming: Turn on the low-vacuum pump group, open the low-vacuum valve, evacuate to below 10Pa, then fill in high-purity argon (5N) until the vacuum gauge is -0.05MPa, repeat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com