Stable machining method for thin-wall edge strip inclined end face structure

A technology of inclined end face and processing method, which is applied in the fields of metal cutting processing and numerical control processing of aeronautical structural parts, can solve the problems of poor stability and low efficiency, and achieve the effect of improving processing stability, simple processing steps, and eliminating bullet knives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

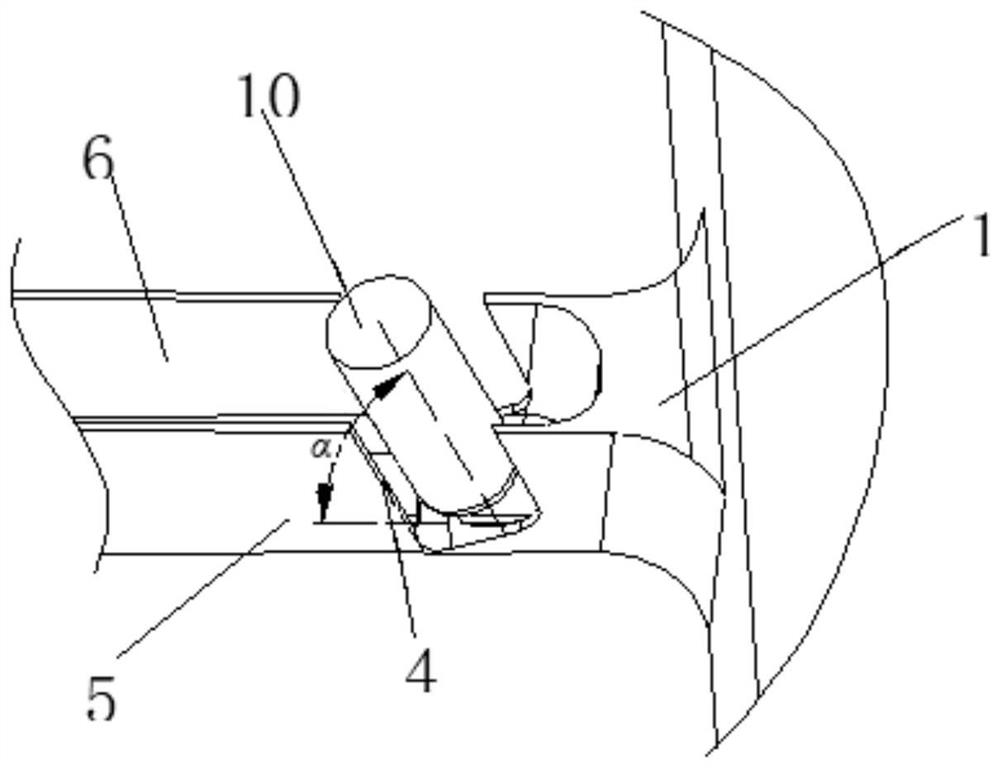

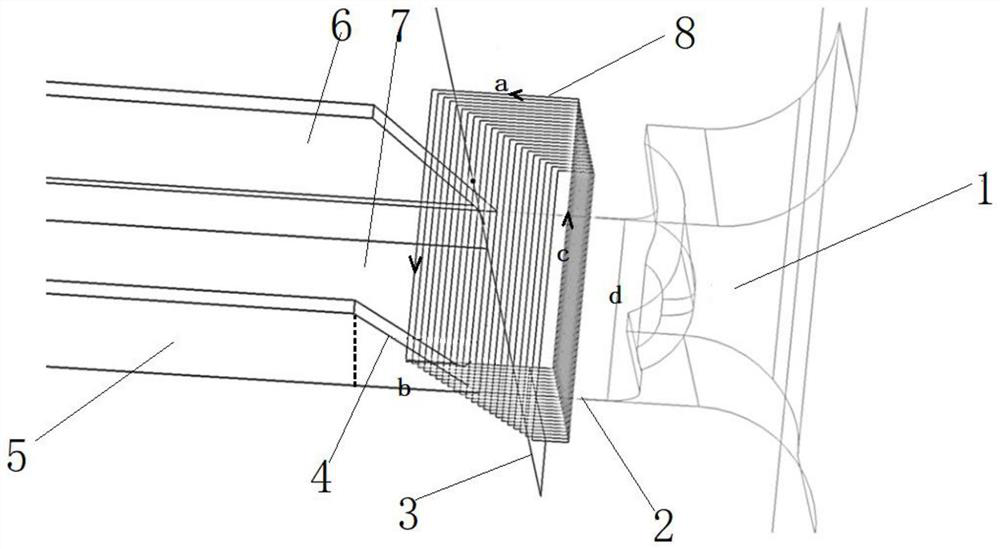

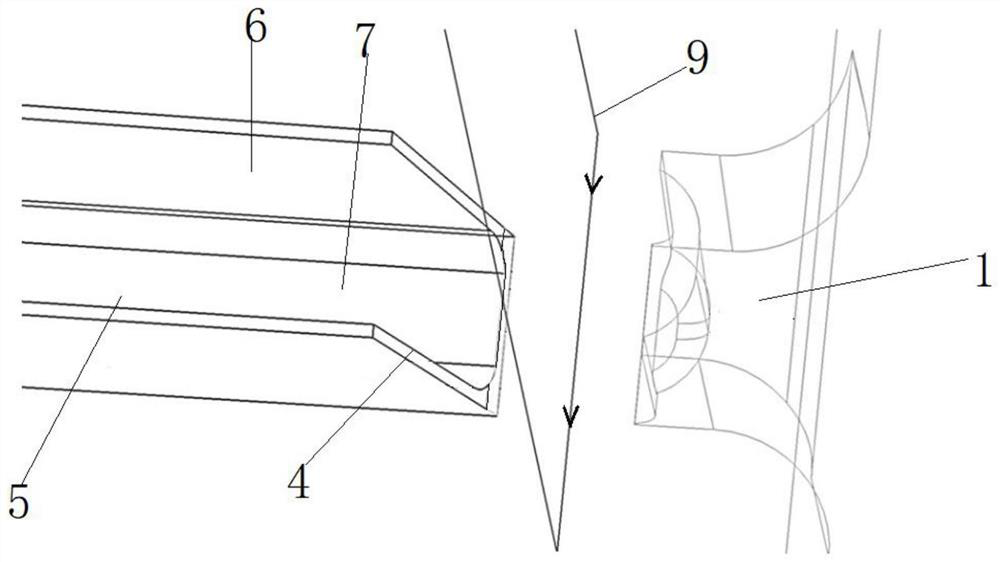

[0034] A processing method of a thin-walled edge strip inclined end surface structure ( Figure 5 ), including the following steps:

[0035] (1) The bottom surface of the web of the cylindrical end mill perpendicular to the thin-walled edge is cut along the design contour of the inclined end face at a fixed axis ( figure 2 ), until there is a 0.5mm thick connection allowance between the bottom surface of the web and the remaining blank, stop the fixed-axis cutting; among them, when the fixed-axis cutting is processed, the cutting depth of each layer is 0.3mm; Climb milling (machine speed S=20000r / min, fixed-axis cutting feed rate F=8000mm / min); the horizontal width a of the fixed-axis cutting track is set to 39mm; the maximum longitudinal width of the fixed-axis cutting track is 47mm;

[0036] (2) Mill the cylindrical end mill perpendicular to the bottom surface of the thin-walled edge web along the sloped end face design contour in one cut (the feed speed of the milling lin...

Embodiment 2

[0039] A processing method for the inclined end surface structure of a thin-walled edge strip, comprising the following steps:

[0040] (1) The cylindrical end mill is perpendicular to the bottom surface of the web of the thin-walled edge, and the fixed axis is cut along the design contour of the inclined end face until there is a 0.8mm thick connection allowance between the bottom surface of the web and the blank, and the fixed axis is stopped. Cutting (machine tool speed S=20000r / min, fixed-axis cutting feed speed F=8000mm / min); among them, during fixed-axis cutting processing, the cutting depth of each layer is 0.2mm; the motion trajectory is one-way down milling ;The horizontal width a of the fixed-axis line cutting track is set to 43mm; the maximum longitudinal width of the fixed-axis line cutting track is 52mm;

[0041] (2) Mill the cylindrical end mill perpendicular to the bottom surface of the thin-walled edge web along the design contour of the inclined end face in on...

experiment example

[0046] The inclined end face structures of thin-walled edge strips were processed by the processing methods in Examples 1-2 of the present invention and Comparative Example 1, respectively, and 20 pieces were processed in each group, and then the numerical control machining time of the inclined end face, the grinding time of fitters and the processing quality of the parts were counted. The results as follows:

[0047] serial number Average time of CNC machining (min) Average time of fitter grinding (min) The number of failures of the NC machining bullet knife Fitter repair file size failure times Pass rate(%) Example 1 1.3 2 0 0 100 Example 2 1.9 2.5 0 0 100 Comparative Example 1 1.1 6 6 1 65

[0048] Through the comparison of the experimental results, it can be seen that using the processing method of the present invention to process the inclined end face structure of the thin-walled edge strip of the aluminum alloy can eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com