Intelligent cooling and lubricating device and method applied to numerical control machine tool

A cooling lubrication, CNC machine tool technology, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of uncut area cooling, single function, large volume, etc. The effect of high level of intelligence and high level of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

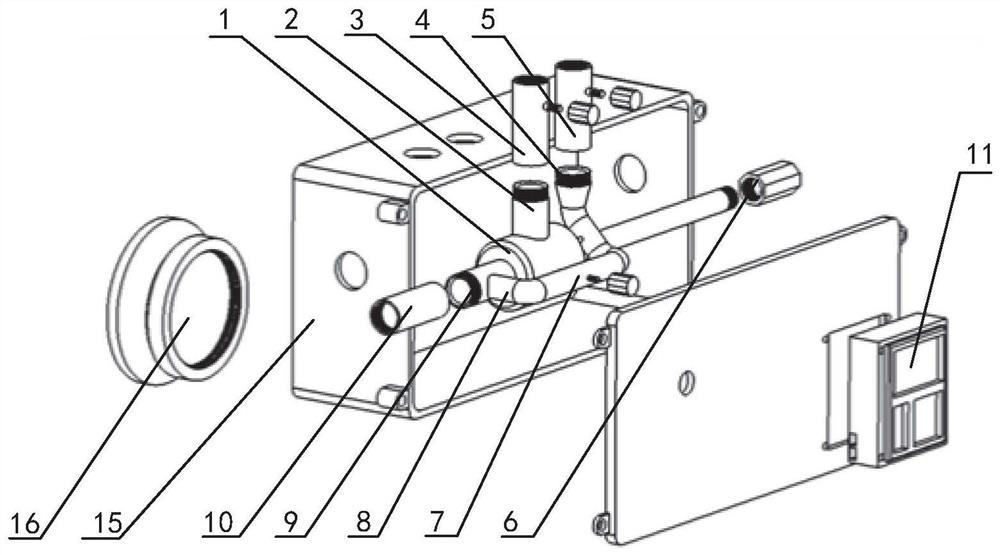

[0043] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

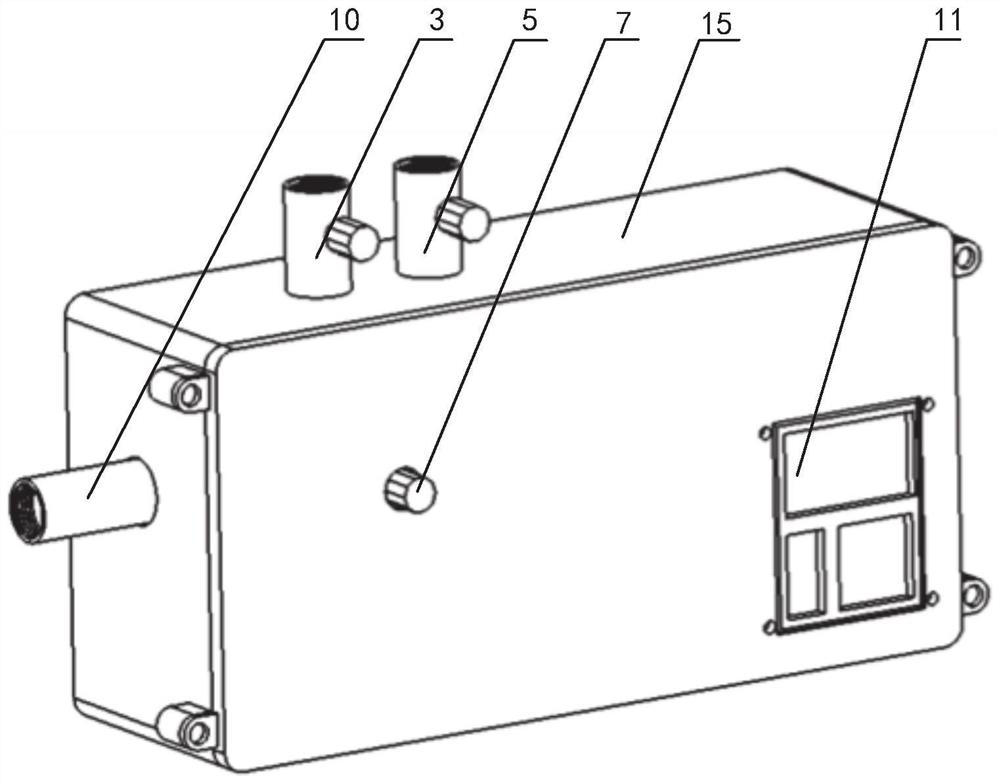

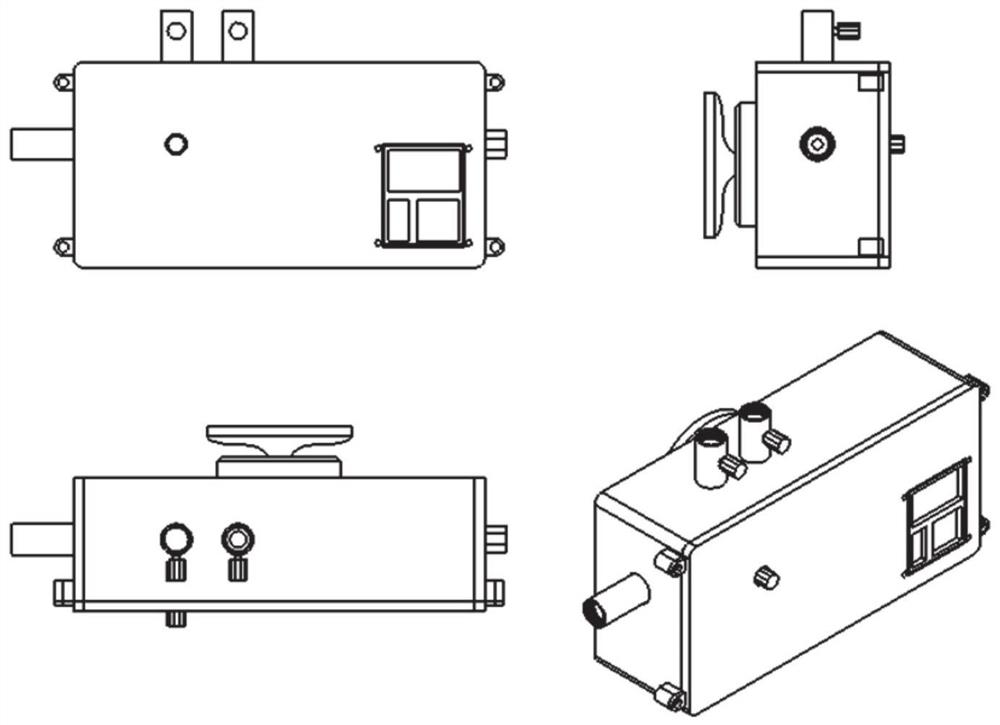

[0044] Such as Figure 1-7 Shown is an integrated design based on the eddy current cooling effect and the principle of micro-lubrication, which is applied to the intelligent cooling and lubrication device of CNC machine tools, including cooling and lubrication system I, condition monitoring system II, sealing module III and convenient installation module IV. in:

[0045] Cooling and lubricating system 1 includes eddy current cooling part 1, air inlet pipe 2, air inlet switch 3, liquid inlet pipe 4, liquid inlet switch 5, temperature regulator 6, flow regulator 7, liquid control flow pipe 8, gas-liquid mixing part 9 and mixed media output pipe 10;

[0046] The state monitoring system II includes a display adjustment component 11, a temperature sensor 12, a flow sensor 13 and a circuit control switch 14;

[0047] The sealing module III mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com