Ship lift balancing weight and preparation device and preparation method thereof

A technology for balancing weights and preparation devices, which is applied in ship lifting devices, vertical lifting ship machinery, surface layering devices, etc., to achieve the effect of high installation accuracy, ensuring pouring quality, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

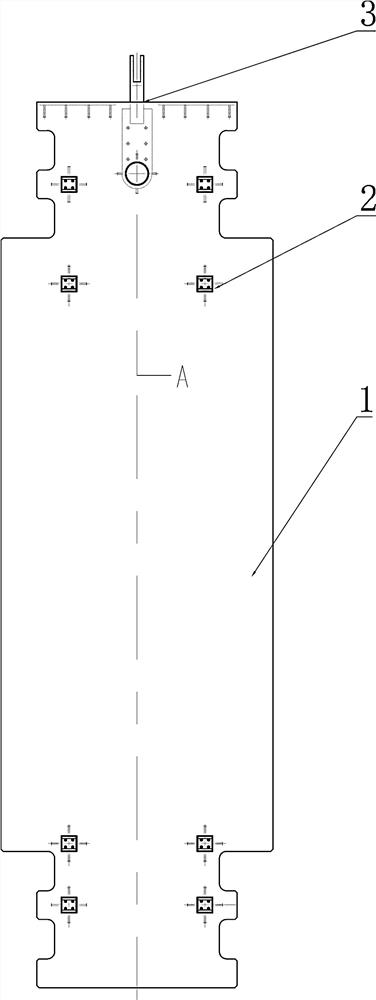

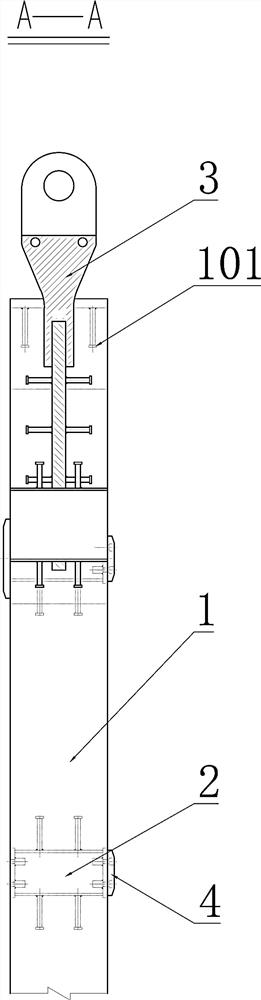

[0073] Such as Figure 1~16 As shown, a ship lift balance weight is made of iron-steel sand concrete with high bulk density, and the aggregate is iron ore, including cement, iron ore, iron ore, and water, which are prepared according to the mix ratio;

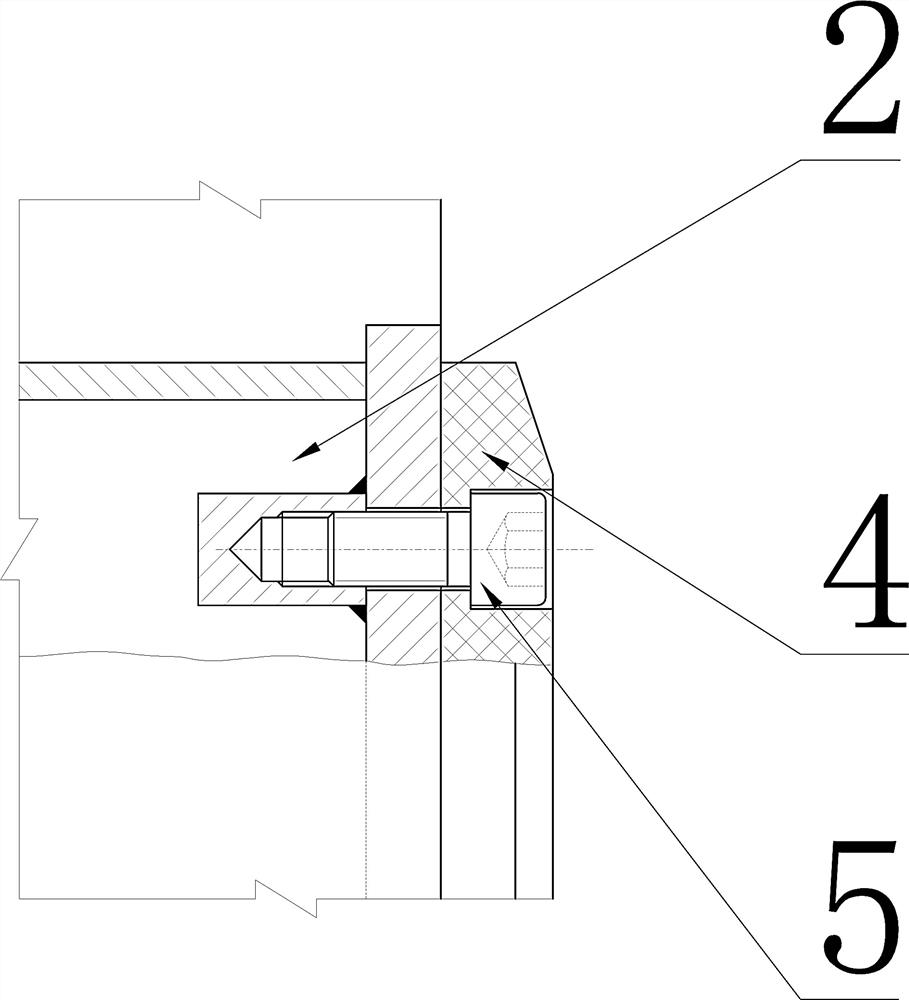

[0074] The top of the balance weight 1 is provided with lifting lugs 3, and the balance weight 1 is also equipped with a plurality of stoppers 2 embedded with seismic loads. One end of the stoppers 2 is also provided with a fixed plate 4, and the fixed plate 4 protrudes from the balance weight. On the end face of the block 1, the fixed plate 4 is connected with the stop block 2 through a plurality of first locking nuts 5;

[0075] The top or bottom of the balance weight 1 is provided with a steel plate 101 for adjusting the balance weight, and the steel plate 101 is embedded in the bottom or top of the balance weight 1 by screws.

[0076] The concrete balance weight of the ship lift is ultra-large and ultra-thin in structure. ...

Embodiment 2

[0088] Further illustrate in conjunction with embodiment 1, as Figure 1-16 The structure shown includes a pouring platform 6 on which the formwork 11 of the balance weight 1 is arranged, and a plurality of second tensioning screws 18 are arranged between the outer wall of the formwork 11 and the pouring platform 6 . In the manufacture of steel structures and concrete blocks in the hydropower industry, the conventionally used load-bearing platforms are generally steel plate platforms. The steel plate platform is generally a welded assembly of section steel and steel plate, which has poor pressure resistance and deformation resistance. The flatness of the surface of the steel platform is deformed during the manufacturing process of the concrete balance weight, resulting in the dimensional accuracy of the bottom surface of the concrete balance weight not meeting the design requirements. . However, although the solid steel platform can meet the technical requirements, the constr...

Embodiment 3

[0102] Further illustrate in conjunction with embodiment 1 and 2, as Figure 1-16 The structure shown is a method for preparing the balance weight of a ship lift. First, the embedded clamping frame 7 is installed inside the demoulding groove 604 of the pouring platform 6, and the upper surface of the embedded clamping frame 7 and the upper surface of the casting platform 6 are adjusted. flat;

[0103] Reassemble the template: install the template 11 on the embedded wheel I-beam of the pouring platform 6 with the embedded contour line 601, and press the bottom of the template 11 through the embedded bolt 21 and the pressure plate 20, and connect multiple templates 11 with the template 11 Place chamfering strips at the upper and lower ends;

[0104] The upper end of the formwork 11 is tightened by the second tensioning screw 18 between the upper end of the formwork 11 and the fixed groove frame 19, and the upper end of the formwork 11 is fixed, and the formwork 11 is built;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com