Preparation method of additive material

A cladding and conditional technology, applied in the field of additive manufacturing, can solve the problems of easy cracking in the transition interface, poor interlayer adhesion, low service life, etc., achieve controllability and reliability, increase strength, and resist. The effect of increased abrasiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

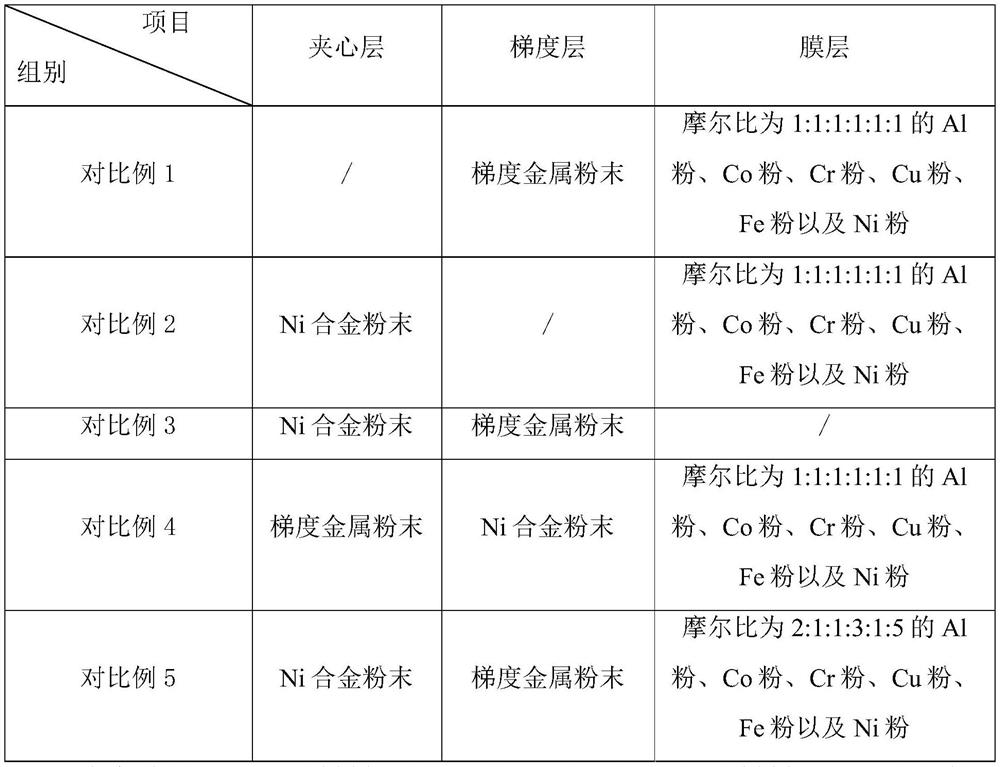

[0023] A method for preparing an additive material in an embodiment of the present invention includes the following steps:

[0024] Carrying out annealing treatment to the substrate layer, after slow cooling, pretreatment, and standby;

[0025] Under the first cladding condition, cladding Ni alloy powder on the base layer to obtain a sandwich layer;

[0026] Under the second cladding condition, the gradient metal powder is clad on the sandwich layer to obtain a gradient layer, and beating treatment is required during the process;

[0027] Recycling the gradient metal powder, cleaning the surface of the gradient layer, and then performing tempering treatment and surface treatment to obtain additive materials;

[0028] Wherein, the surface treatment is: using Al powder, Co powder, Cr powder, Cu powder, Fe powder and Ni powder in equimolar ratio to form a film layer by DC magnetron sputtering method.

[0029] In one of the embodiments, the base layer is a steel base.

[0030] ...

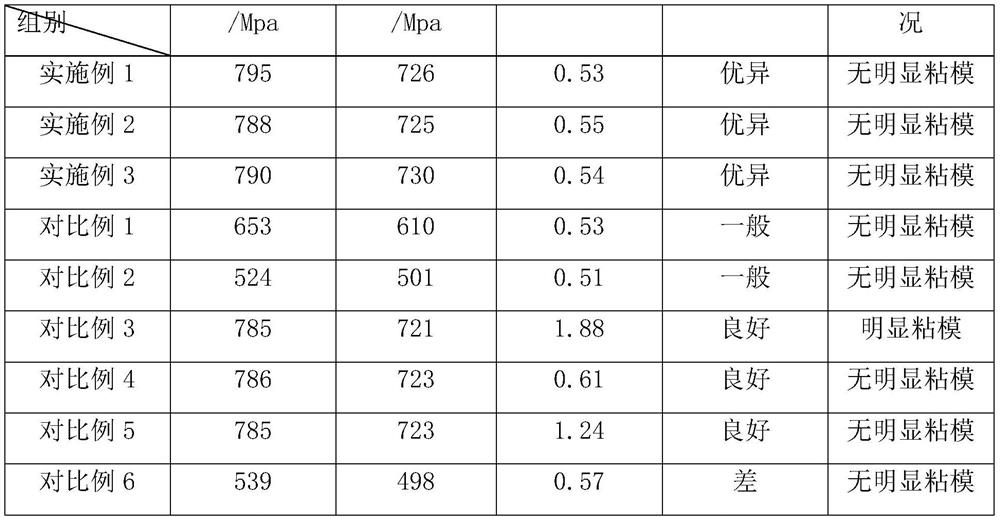

Embodiment 1

[0056] A method for preparing an additive material, comprising the steps of:

[0057] Anneal the steel substrate at 1100°C for 100s, after slow cooling, clean and dry the surface of the steel substrate, heat it to 300°C, and keep it warm for later use;

[0058] Under the conditions of power of 1200W, scanning speed of 550mm / min, light spot of 2mm, powder feeding rate of 1.2r / min, carrier gas volume of 4L / min, and Ar gas flow rate of 15L / min, the Ni alloy powder was melted. Overlay on the steel matrix to obtain a sandwich layer with a thickness of 0.5mm;

[0059] The Co powder, Cr powder, Cu powder, Fe powder, and Ni powder are prepared according to the molar ratio of 1:1:1:1:1 to obtain a gradient metal powder. The power is 1300W and the scanning speed is 600mm / min. The light spot is 2mm, the carrier gas volume is 4L / min, and the gradient metal powder is cladding on the described sandwich layer under the condition that the gas flow rate of Ar gas is 15L / min, and the formation...

Embodiment 2

[0063] A method for preparing an additive material, comprising the steps of:

[0064] Anneal the steel substrate at 1000°C for 160s, after slow cooling, clean and dry the surface of the steel substrate, heat it to 300°C, and keep it warm for later use;

[0065] Under the conditions of power of 1200W, scanning speed of 600mm / min, light spot of 2mm, powder feeding rate of 1.2r / min, carrier gas volume of 4L / min, and Ar gas flow rate of 15L / min, the Ni alloy powder was melted Overlay on the steel matrix to obtain a sandwich layer with a thickness of 0.5mm;

[0066] The Co powder, Cr powder, Cu powder, Fe powder, and Ni powder are prepared according to the molar ratio of 1:1:1:1:1 to obtain a gradient metal powder. The power is 1300W and the scanning speed is 600mm / min. The light spot is 2mm, the carrier gas volume is 4L / min, and the gradient metal powder is cladding on the described sandwich layer under the condition that the gas flow rate of Ar gas is 15L / min, and the formation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com