Static and dynamic three-dimensional microcrack propagation sensor preparation method, sensor and equipment

A micro-crack, static and dynamic technology, applied in the field of sensors, can solve the problems of loss of conductive layer, insensitivity to strain rate, poor flexibility of zinc sheets, etc., and achieve the effects of flexible size adjustment, fast and stable monitoring, and favorable sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

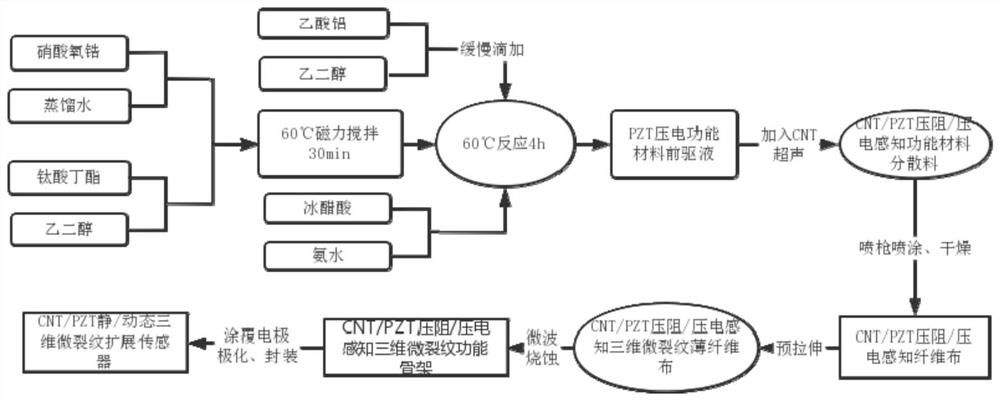

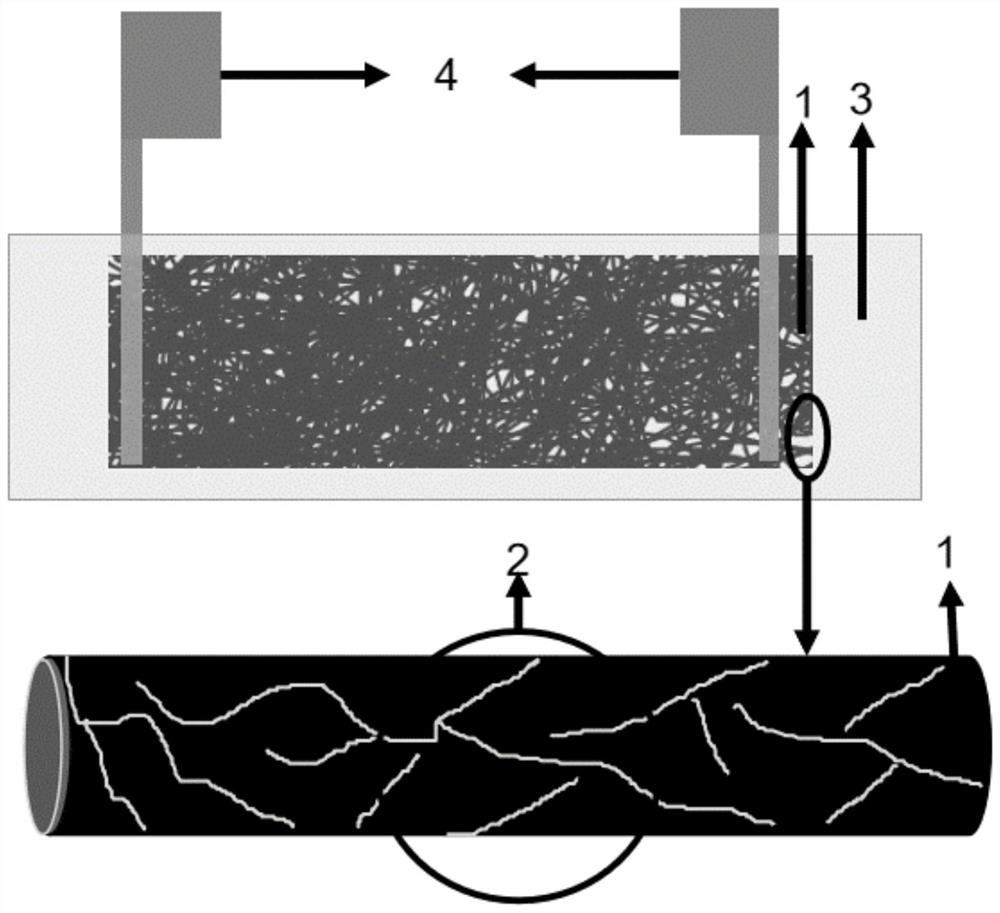

[0043] refer to figure 1 , the present embodiment provides a static and dynamic three-dimensional micro-crack growth sensor preparation method, which includes:

[0044] Step 1: Prepare a piezoresistive / piezoelectric sensing functional material dispersion and attach it to the surface of the fiber cloth substrate to obtain a piezoresistive / piezoelectric sensing fiber cloth.

[0045] In step 1, the process of preparing piezoresistive / piezoelectric sensing functional material dispersion is:

[0046] Prepare piezoelectric functional material precursors;

[0047] Using the method of ultrasonic surfactant, the material with piezoresistive function is mixed and dispersed in the precursor liquid of piezoelectric functional material to obtain the dispersion material of piezoresistive / piezoelectric sensing functional material.

[0048] Wherein, the preparation of the piezoelectric functional material precursor can be prepared by a sol-gel method well known to those skilled in the art. T...

Embodiment 2

[0082] This embodiment provides a method for preparing a static and dynamic three-dimensional micro-crack growth sensor, which is different from the first embodiment in that the piezoresistive / piezoelectric sensing functional material in step 1 is different, and other steps are similar to the first embodiment.

[0083] In this embodiment, the preparation process of CNT piezoresistive sensing functional material dispersion is as follows:

[0084] Add 3 parts of CTAB and 1 part of CNT into 500 parts of deionized water, immerse the dispersion in ultrasonication for 5 minutes, and ultrasonicate with a 200W probe for 30 minutes to obtain a CNT slurry.

[0085] The process of introducing the CNT piezoresistive sensing functional material into the fiber cloth matrix is as follows: refer to Step 1.1 and Step 1.2 in Example 1, dry at 80°C for 15 minutes after spraying, and repeat Step 1.4.

[0086] The process of introducing nano-zinc oxide (ZnO) piezoelectric sensing functional mate...

Embodiment 3

[0091] This embodiment provides a static and dynamic three-dimensional micro-crack propagation sensor preparation method, which is different from the first embodiment in that the piezoresistive sensing functional material used is reduced graphene oxide (rGO); the piezoelectric sensing functional material is nano-zinc oxide.

[0092] quasi-static d 33 / d 31 Measuring instrument to test the piezoelectric strain coefficient d of the rGO / ZnO piezoresistive / piezoelectric sensing three-dimensional microcrack functional skeleton 33 -25pC / N, d 31 It is -28pC / N, combined with Wheatstone bridge technology and DaspV11 dynamic signal acquisition technology to study the change of resistivity of the sensor under the condition of three-point bending in the middle span of simply supported beam system, the sensitivity is 211, the linearity is 0.98, and the dynamic When the strain acts, the sensor voltage change sensitivity is 220, and the linearity is 0.99. It can sensitively sense the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com