Method for quantitatively testing bonding strength of coating and plating layer on surface of material and matrix

A technology combining strength and matrix, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as unusable coating, unsuitable coating, and error in test results, so as to improve measurement accuracy, good quantification, and reduce Effect of Small Measurement Errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

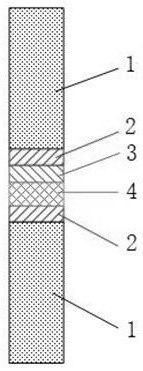

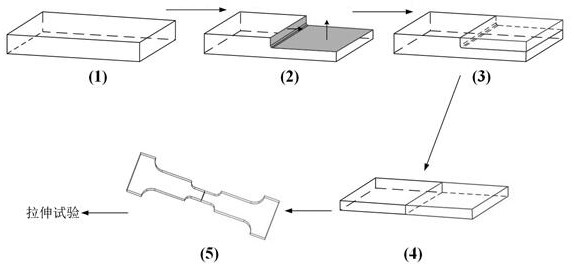

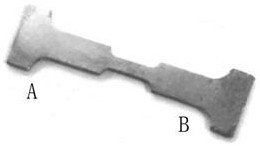

[0043] Prepare two block copper substrates, and press figure 2 According to the method, the copper substrate is cut, and the nickel-cobalt alloy is plated on the cut surface, and then the copper substrate under the nickel-cobalt coating is cut off, so as to obtain two sample samples in which the nickel-cobalt coating and the substrate each account for half, and then The two samples were cut and processed separately to obtain the following image 3 For the tensile specimen shown, the maximum length and width of the tensile specimen are 14×4 mm, and the thickness is 0.5 mm. image 3 Side A is nickel-cobalt coating, and side B is copper substrate.

[0044] One of the tensile samples is loaded on the tensile equipment platform, and the tensile test is carried out. The tensile rate is 1 μm / s. The obtained tensile stress-strain curve is as follows: Figure 4As shown in the figure, it can be seen that the interface between the nickel-cobalt coating and the copper substrate has a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com