Light emitting diode and preparation method thereof

A technology of light-emitting diodes and light-emitting layers, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low electron-hole radiation recombination efficiency and hole injection efficiency, and achieve enhanced radiation recombination efficiency and increased hole concentration , increase the effect of hole injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The present invention also provides a method for preparing the light-emitting diode as described above, comprising the following steps:

[0081] growing an N-type semiconductor layer 2, a multi-quantum well light-emitting layer 3 and a P-type semiconductor layer 4 sequentially on the surface of the substrate 1 to obtain the light-emitting diode;

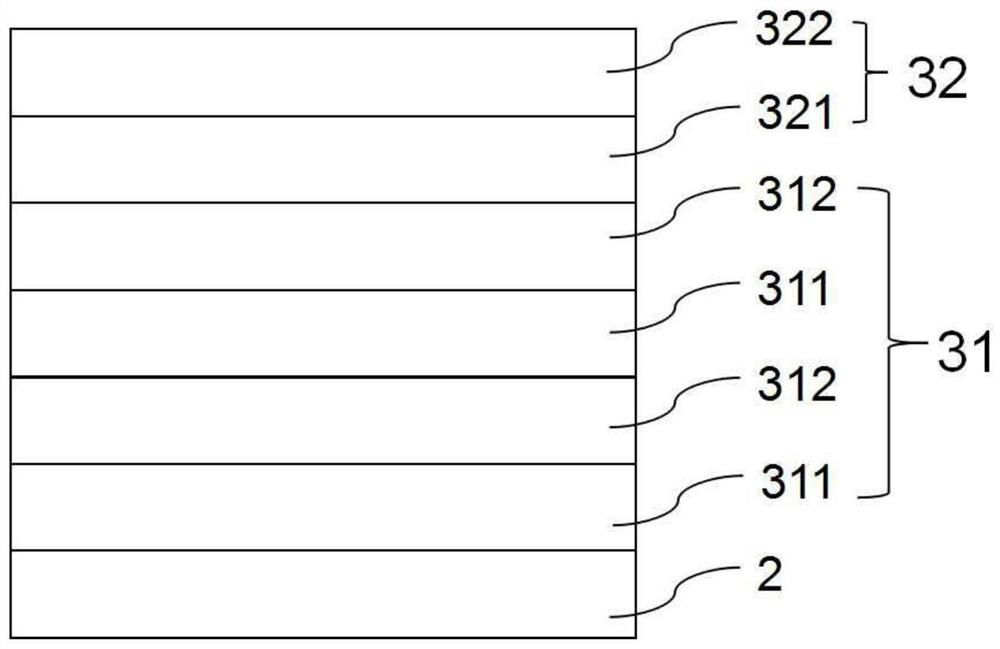

[0082] Wherein, the preparation method of the multi-quantum well light-emitting layer 3 specifically includes: periodically and alternately growing the first quantum well layer 311 and the quantum barrier layer 312 on the surface of the N-type semiconductor layer 2 to obtain the first sub-layer 31; and then growing a second quantum well layer 321 and a superlattice structure barrier layer 322 sequentially on the surface of the first sublayer 31 to obtain a second sublayer 32;

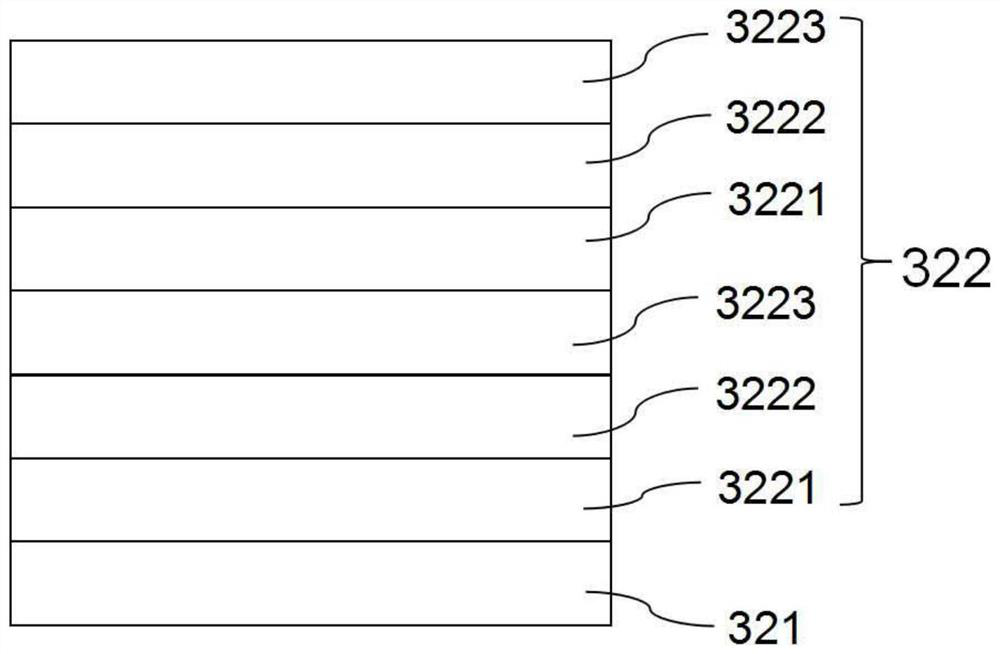

[0083] The superlattice structure barrier layer 322 includes a GaN layer 3221, an AlGaN layer 3222 and a P-type layer 3223 that are periodically and al...

Embodiment 1

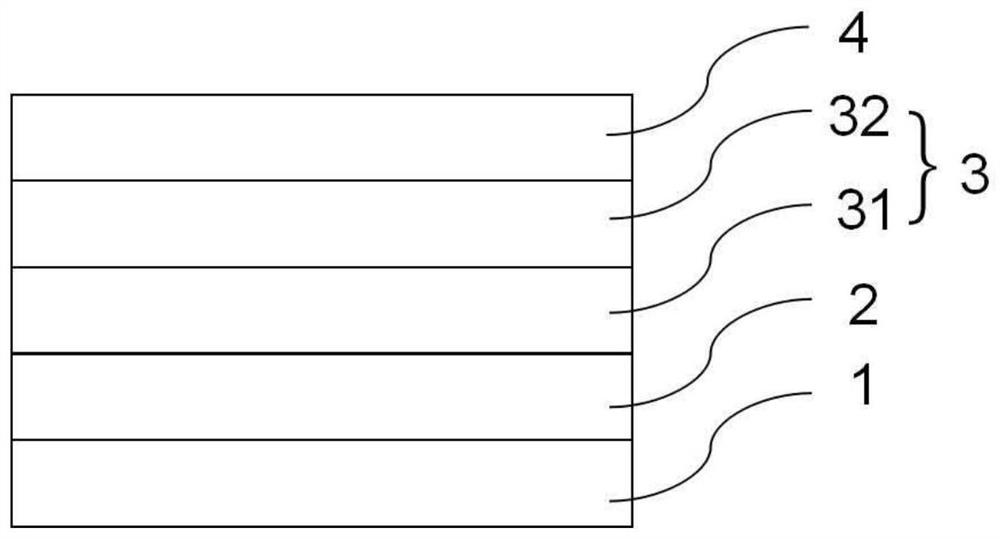

[0133] The light emitting diode provided in this embodiment includes: a substrate 1 (sapphire substrate 1 ), and an N-type semiconductor layer 2 , a multi-quantum well light-emitting layer 3 and a P-type semiconductor layer 4 sequentially stacked on the surface of the substrate 1 . Its structure can be found in Figure 4 .

[0134] Among them, such as Figure 5 As shown, the multi-quantum well light-emitting layer 3 includes a first sublayer 31 and a second sublayer 32 sequentially stacked on the surface of the N-type semiconductor layer 2; the first sublayer 31 is included in the N-type semiconductor layer 2 The surface of the type semiconductor layer 2 is a first quantum well layer 311 (InGaN) and a quantum barrier layer 312 (GaN) that are alternately stacked in 5 cycles; the second sublayer 32 is composed of The second quantum well layer 321 (InGaN) and the superlattice structure barrier layer 322 are stacked.

[0135] like Figure 6 As shown, the superlattice barrier l...

Embodiment 2

[0152] The structure of the light emitting diode provided by this embodiment is basically the same as that of Embodiment 1, the difference is:

[0153] First, the superlattice structure barrier layer 322 includes GaN layers 3221, AlGaN layers 3222, and P-type layers 3223 that are alternately stacked in three cycles; wherein, the P-type layers in the first cycle and the second cycle Layer 3223 is an AlGaN layer doped with P-type dopants (AlGaN layer doped with Mg), and the P-type layer 3223 in the third period (ie, the last period, the last barrier layer) is doped with P-type dopant agent GaN layer (GaN layer doped with Mg).

[0154] Second, the alternating cycle of the first sub-layer 31 is 8.

[0155] Third, the GaN layer 3221 in the superlattice structure barrier layer 322 has a thickness of 2.1 nm, the AlGaN layer 3222 has a thickness of 0.5 nm, and the P-type layer 3223 has a thickness of 0.5 nm.

[0156] The preparation method of the light-emitting diode provided in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com