Hydrogen fuel cell metal bipolar plate resistant to long-term corrosion

A metal bipolar plate, fuel cell technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low contact resistance of the coating, the coating is not resistant to long-term corrosion, etc., to achieve low contact resistance and excellent corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

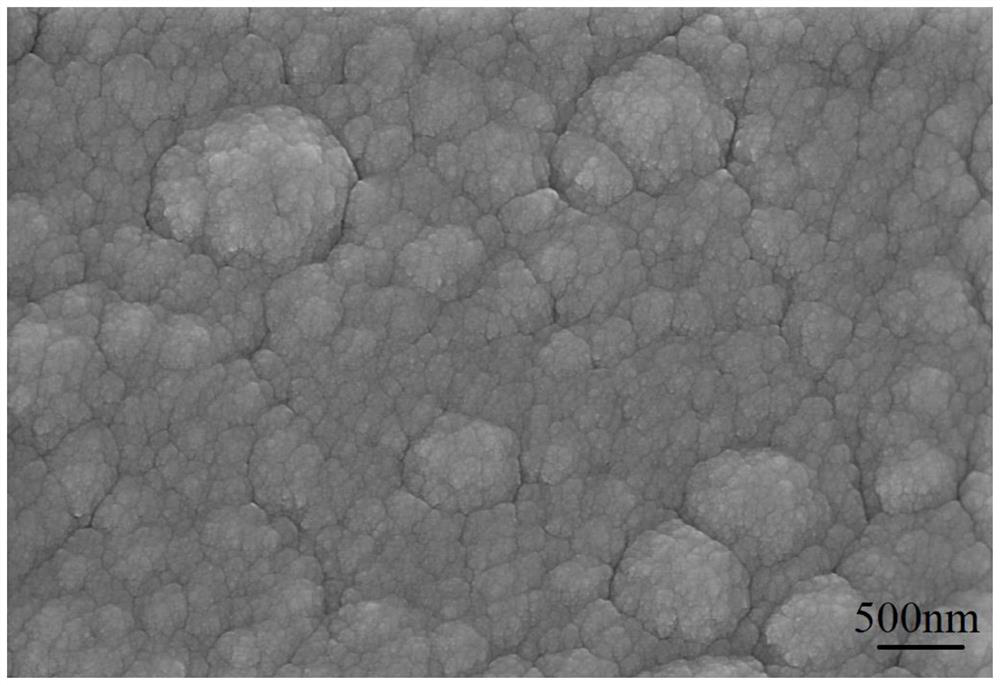

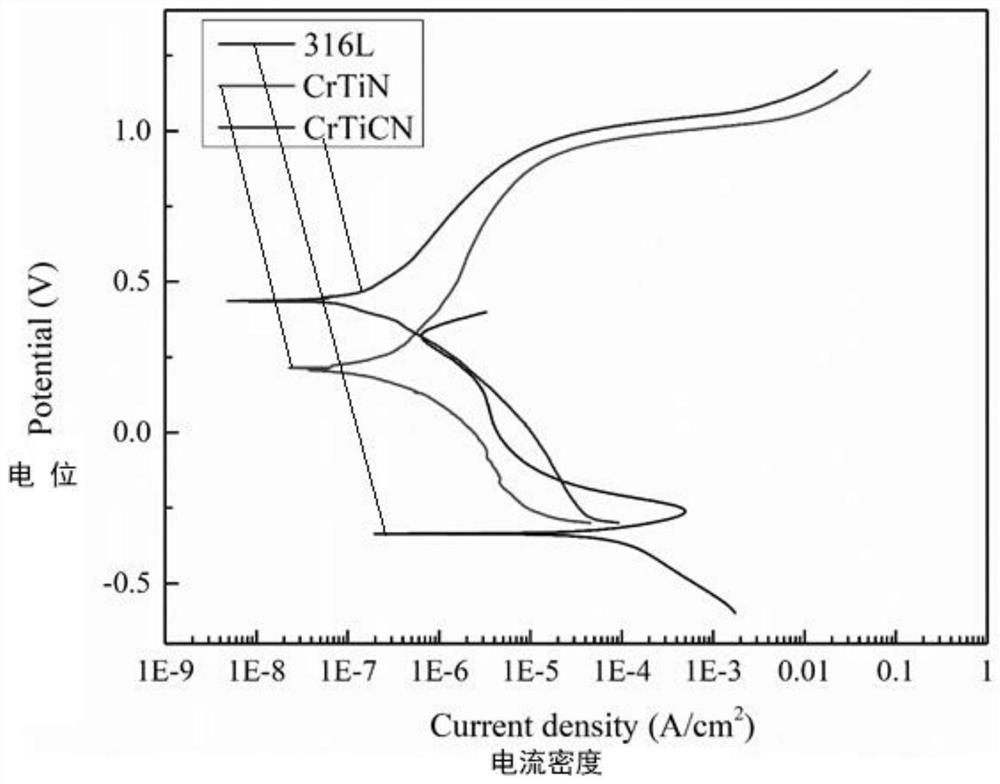

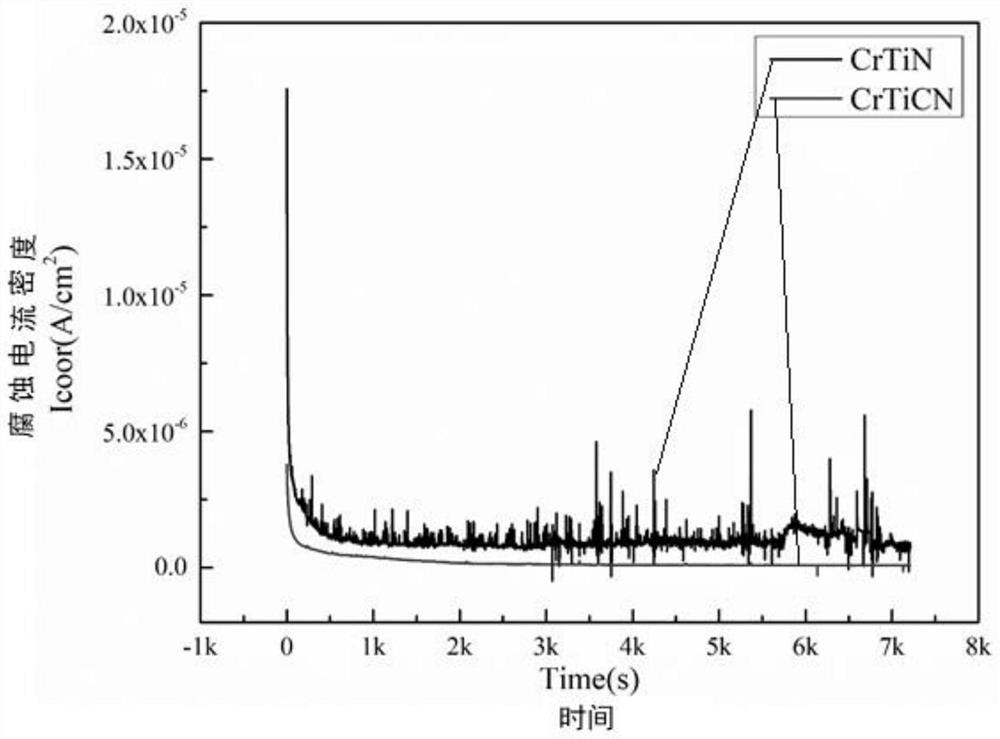

[0035] A hydrogen fuel cell metal bipolar plate resistant to long-term corrosion, including a metal bipolar plate with a coating on the surface, the material of the metal bipolar plate is 316L stainless steel, the size of the metal bipolar plate is 20mm×20mm×8mm, the coating From the surface of the metal bipolar plate to the outside, there are Cr coating, CrN coating and CrTiCN coating in sequence.

[0036] The preparation method comprises the following steps:

[0037] (1) Pretreat the surface of the metal bipolar plate to obtain a clean surface of the metal bipolar plate; the pretreatment is: first use sandpaper to polish the surface of the metal bipolar plate, then polish it with a polishing machine, rinse it with distilled water, and then immerse it in Ultrasonic cleaning in ethanol and acetone solution for 30min, and drying.

[0038] (2) Put the pretreated metal bipolar plate into the vacuum chamber of the magnetron sputtering machine, and pump the pressure in the vacuum ...

Embodiment 2

[0045]A hydrogen fuel cell metal bipolar plate, comprising a metal bipolar plate with a coating on the surface, the material of the metal bipolar plate is titanium alloy, the size of the metal bipolar plate is 20mm×20mm×8mm, and the coating is made of metal bipolar plate From the surface of the plate to the outside, there are Cr coating, CrN coating and CrTiCN coating in sequence.

[0046] The preparation method comprises the following steps:

[0047] (1) Pretreat the surface of the metal bipolar plate to obtain a clean surface of the metal bipolar plate; the pretreatment is: first use sandpaper to polish the surface of the metal bipolar plate, then polish it with a polishing machine, rinse it with distilled water, and then immerse it in Ultrasonic cleaning in ethanol and acetone solution for 30min, and drying.

[0048] (2) Put the pretreated metal bipolar plate into the vacuum chamber of the magnetron sputtering machine, and pump the pressure in the vacuum chamber to 2×10 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com