Metal-N4 doped carbon catalyst with high oxygen reduction performance and preparation method thereof

A carbon catalyst and metal technology, which is applied in the field of high-performance carbon catalysts and the preparation of metal-N4 active site growth induced by synergistic effect, can solve the problems of poor catalytic ORR ability, loss of active sites, restricting catalytic performance, etc. The effect of aggregation, ease of operation, and excellent catalytic activity for oxygen reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, a Fe-N x -C carbon catalyst.

[0036] In this example, iron phthalocyanine was used to prepare Fe-N x The method of -C carbon catalyst, comprises the steps:

[0037] 200 mg iron phthalocyanine (FePc, purchased from AlfaAesar), 200 mg phthalocyanine (Pc, purchased from aladdin) and 400 mg zinc chloride (ZnCl 2 , purchased from aladdin), ultrasonically dispersed into 20mL of absolute ethanol, ultrasonically mixed until uniform, and continued to heat ultrasonically to completely evaporate the liquid solvent, after drying, it was pyrolyzed at 950°C for 1h under the protection of high-purity argon to prepare iron-nitrogen doped heterogeneous carbon catalysts (Fe-N x -C).

[0038] Experimental test analysis:

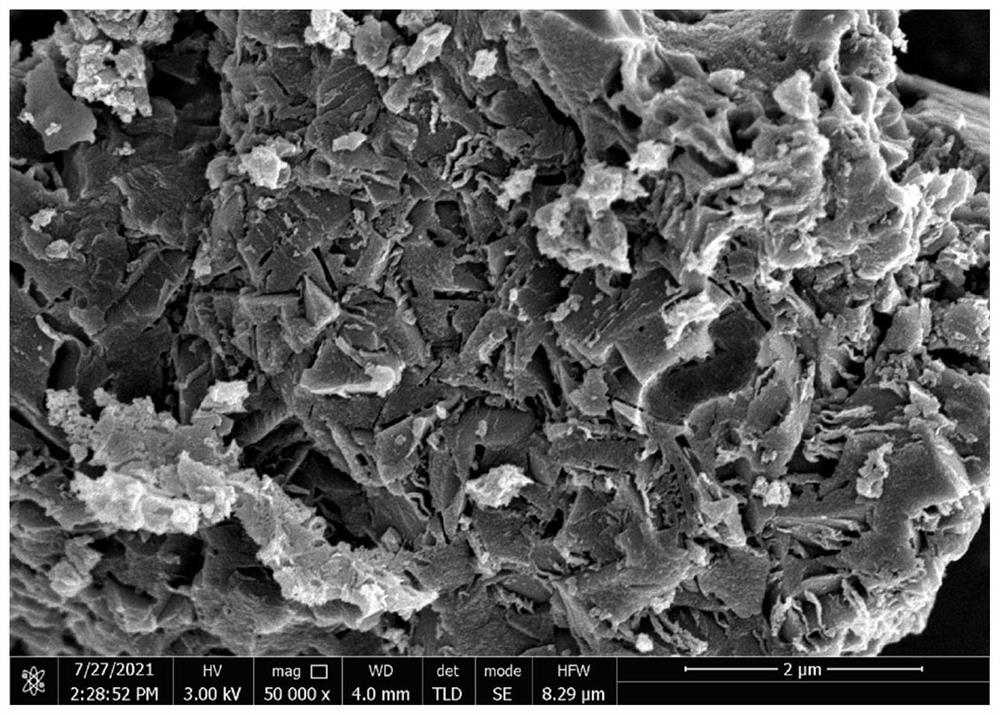

[0039] 1) For the present embodiment Fe-N x The morphology of -C carbon catalyst was observed microscopically, and its morphology and structure were as follows figure 1 SEM shown. It can be seen from the topography that the carbon catalyst has a...

Embodiment 2

[0050] This embodiment is basically the same as Embodiment 1, and the special features are:

[0051] In this example, Fe-N was prepared by pyrolysis for 0.5 hours x -C carbon catalyst, comprising the steps of:

[0052] 200 mg iron phthalocyanine (FePc, purchased from AlfaAesar), 200 mg phthalocyanine (Pc, purchased from aladdin) and 400 mg zinc chloride (ZnCl 2 , purchased from aladdin), ultrasonically dispersed into 20mL of absolute ethanol, ultrasonically mixed until uniform, and continued to heat ultrasonically to completely evaporate the liquid solvent, after drying, it was pyrolyzed at 950°C for 0.5h under the protection of high-purity argon to prepare iron nitrogen Doped carbon catalysts (Fe-N x -C).

[0053] Experimental test analysis:

[0054] 1) Test the oxygen reduction activity of the carbon catalyst of this embodiment:

[0055] Fe-N x -C carbon catalyst loading is 600μg / cm 2 , 20wt% Pt / C catalyst loading is 75μg / cm 2 They were coated on the surface of glass...

Embodiment 3

[0059] This embodiment is basically the same as the previous embodiment, and the special features are:

[0060] In this example, Fe-N was prepared by pyrolysis for 1.5 hours x -C carbon catalyst, comprising the steps of:

[0061] 200 mg iron phthalocyanine (FePc, purchased from AlfaAesar), 200 mg phthalocyanine (Pc, purchased from aladdin) and 400 mg zinc chloride (ZnCl 2 , purchased from aladdin), ultrasonically dispersed into 20mL of absolute ethanol, ultrasonically mixed until uniform, and continued to heat ultrasonically to completely volatilize the liquid solvent, after drying, it was pyrolyzed at 950°C for 1.5h under the protection of high-purity argon to prepare iron nitrogen Doped carbon catalysts (Fe-N x -C).

[0062] Experimental test analysis:

[0063] 1) test the present embodiment Fe-N x Oxygen reduction activity of -C carbon catalysts:

[0064] Fe-N x -C carbon catalyst loading is 600μg / cm 2 , 20wt% Pt / C catalyst loading is 75μg / cm 2 They were coated on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com