Radish pickling equipment

A radish and equipment technology, applied in the field of radish pickling equipment, can solve the problems of high labor intensity and low pickling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

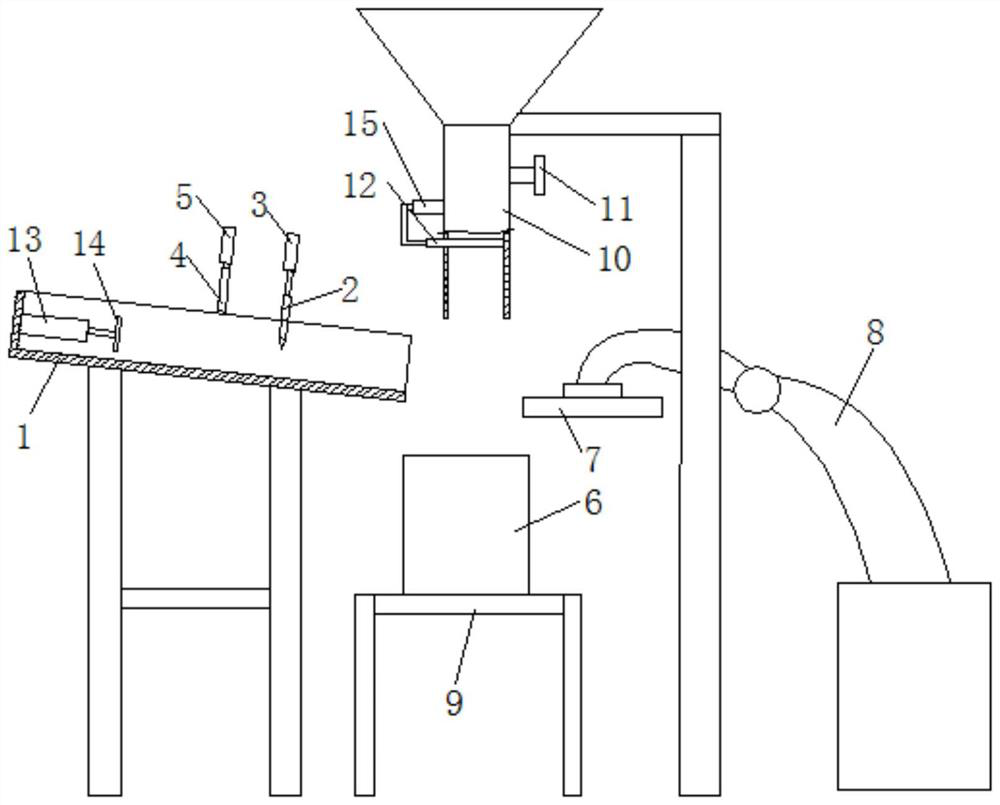

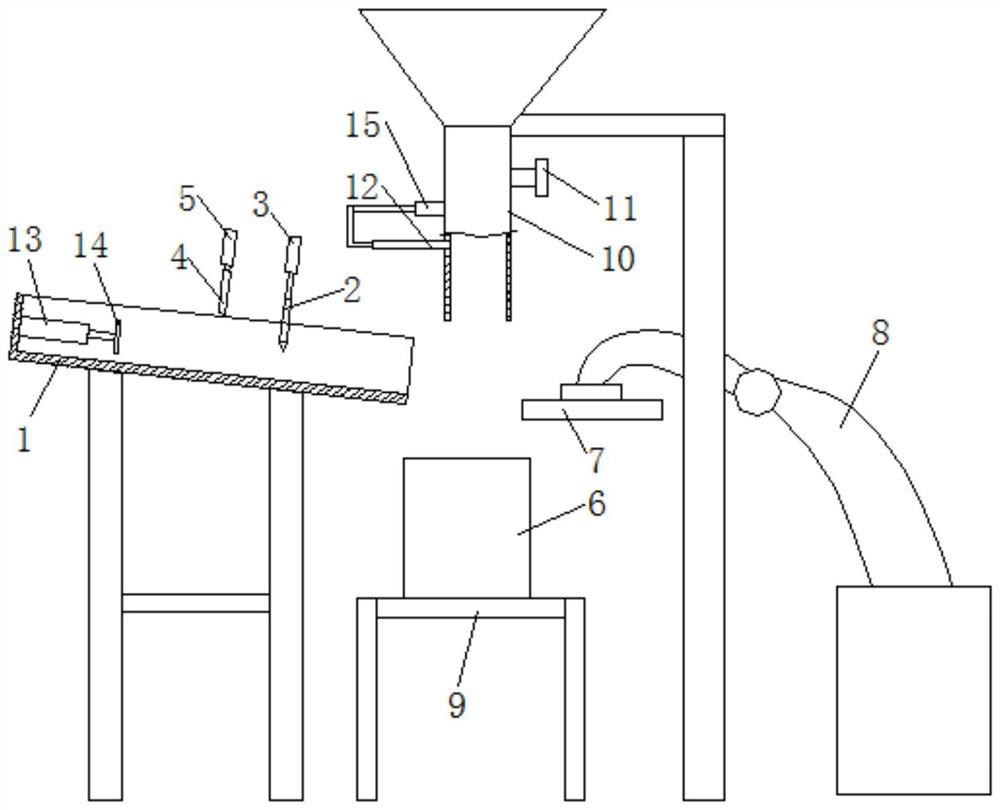

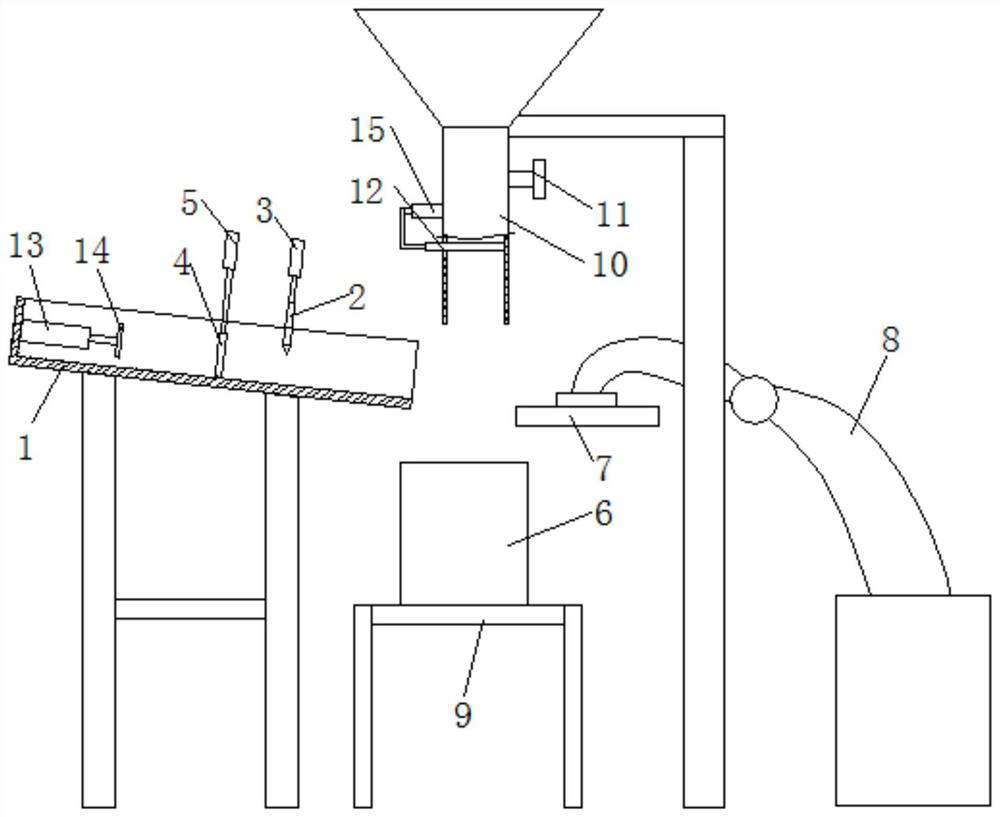

[0039] like Figure 1 to Figure 5 As shown, this embodiment provides a radish pickling device, including a cutting device, an adding device and a holding device for storing and pickling radishes; the cutting device is installed next to the holding device for cutting radish and sending The holding device; the adding device is installed next to the holding device, and is used to deliver the marinade to the holding device.

[0040] When pickling, first, the radish is cut by the cutting device, and the cut radish is sent to the holding device; then, the marinade is sent to the holding device by the adding device, and the radish is pickled in the holding device, The automatic pickling of radish is realized, and the pickling efficiency is high.

[0041] This embodiment has a compact structure, and can complete processes such as automatic cutting of radishes, adding marinade, and pickling to realize automatic pickling of radishes, with high pickling efficiency and low labor intensit...

Embodiment 2

[0043] On the basis of Embodiment 1, in this embodiment, the holding device includes a plurality of pickling tanks 6 with open upper ends, and the plurality of pickling tanks 6 are evenly spaced; the cutting device and the adding device are respectively located in multiple pickling tanks. Next to tank 6.

[0044] When pickling, the radish is cut by the cutting device and sent to the pickling tank 6; at the same time, the marinade is sent to the pickling tank 6 by the adding device to pickle the radish.

[0045]It should be noted that, during this process, since the positions of the cutting device and the adding device remain unchanged, a plurality of pickling tanks 6 can be sent to the processing position manually at this time, when any one of the pickling tanks 6 is filled with radish And after adding the marinade, the pickling tank 6 is manually moved out of the processing position, and the next pickling tank 6 is sent to the processing position, and the above operations are...

Embodiment 3

[0047] On the basis of embodiment 2, the present embodiment also includes a conveying device 9, and a plurality of pickling tanks 6 are evenly spaced on the conveying device 9 along the conveying direction of the conveying device 9; sides. During pickling, a plurality of pickling tanks 6 are evenly distributed on the conveying device 9, and the multiple pickling tanks 6 are sequentially sent to the processing position through the conveying device 9, so as to realize automatic transportation of the pickling tanks 6, and the pickling efficiency is high.

[0048] Preferably, in this embodiment, the above-mentioned conveying device 9 is preferably a belt conveyor. When pickling, the empty pickling tank 6 can be placed on the feeding end of the belt conveyor in turn by manual or mechanical means, and sent to the processing position in turn; the cut radish can be sent to the pickling tank 6 through the cutting device After the pickling material is delivered to the marinating tank 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com