Continuous fixed bed adsorption device and method

A fixed bed adsorption, screw conveyor technology, applied in the direction of solid adsorbent liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of inability to continuously operate, difficult to discharge silica gel, low processing efficiency, etc., to ensure adsorption. efficiency, reducing the cost of regeneration treatment, and ensuring the effect of oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

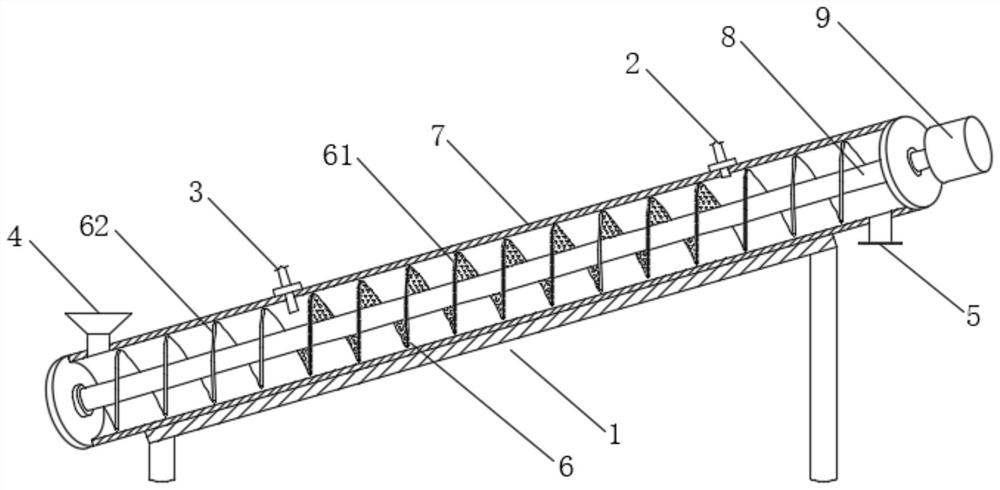

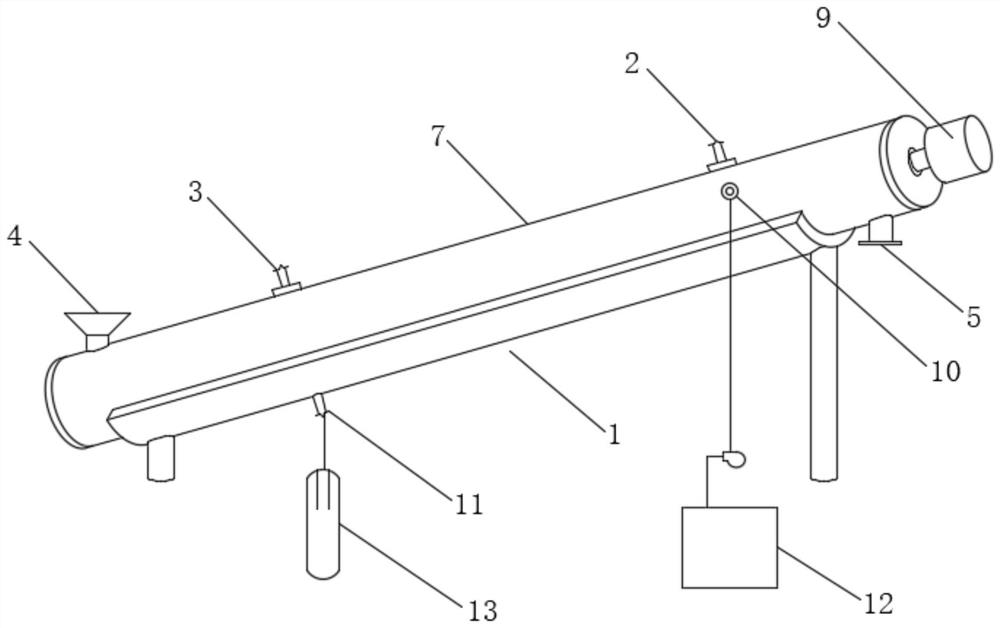

[0028] Such as Figure 1-2 As shown, a continuous fixed bed adsorption device includes a screw conveyor 1, and an oil inlet 2 connected to the screw conveyor 1, an oil outlet 3, a silica gel inlet 4 and a waste rubber outlet 5; wherein,

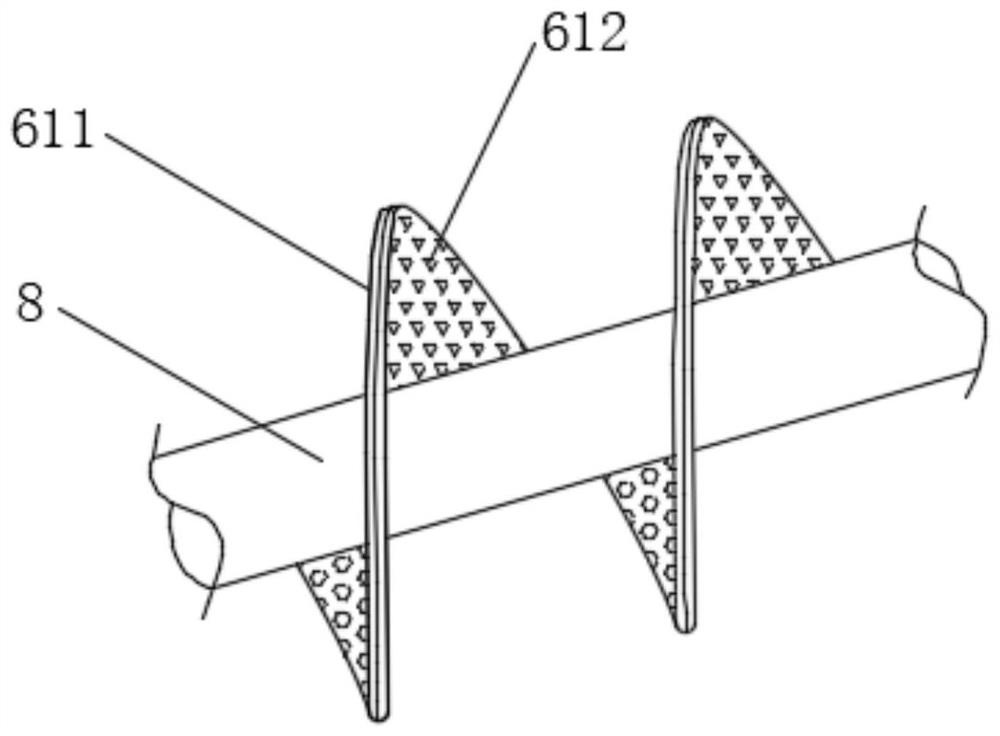

[0029] The screw conveyor 1 includes a body 7, a rotating shaft 8 which is arranged in the body 7 and drives the screw blade 6 to rotate, and a motor 9 which drives the rotation of the rotating shaft 8, and the screw blade 6 is bonded to the inner wall of the body 7; The screw conveyor 1 is arranged obliquely, and the screw blade 6 in its inner chamber is made up of a blade with holes 61 and a solid blade 62 connected to the two ends of the blade with holes 61; Composed of two layers, the wire mesh 612 is fixedly arranged on the side of the supporting orifice plate 611 close to the conveying direction of the screw conveyor 1, and the aperture of the supporting orifice plate 611 and the mesh aperture of the wire mesh 612 are smaller than the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com