Device and method for low-temperature variable-pressure absorption of chloromethane in waste gas by using ionic liquid

A technology of ionic liquid and methyl chloride, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve secondary pollution and other problems, and achieve the effects of convenient operation, cost reduction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

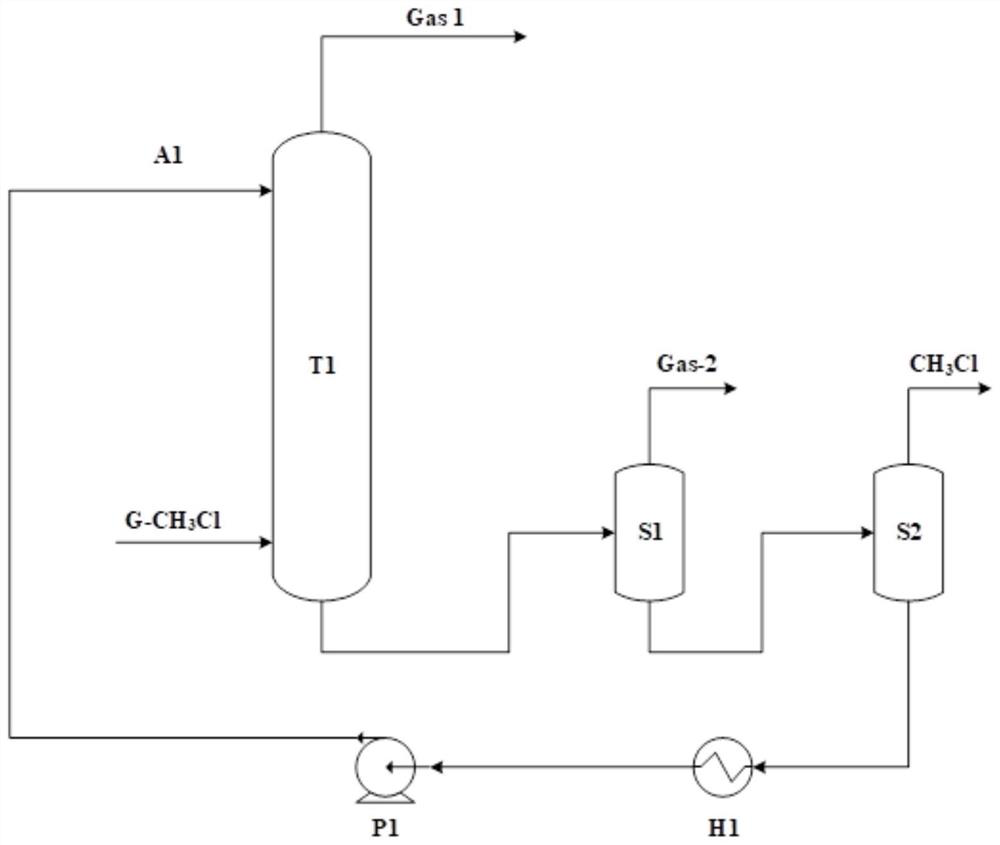

Image

Examples

Embodiment 1

[0038] Using a single ionic liquid (take [EMIM][Ac] as an example)

[0039] The feed flow rate of waste gas containing chloromethane is 100kg / h, and the feed contains 5% (mass fraction) of chloromethane, 1% (mass fraction) of water, 0.1% dimethyl ether (mass fraction), and the balance is nitrogen. The theoretical plate number of the gas absorption tower (T1) is 8, the feeding position of the waste gas containing chloromethane is the 8th block, and a single ionic liquid (taking [EMIM][Ac] as an example) is fed from the 8th block of the gas absorption tower (T1). Feeding at one plate position, the operating pressure and temperature of the gas absorption tower (T1) are 2.2atm and 30°C, respectively, the mass ratio of the ionic liquid to the waste gas containing chloromethane during the absorption process is 2:1, and the first flash tank The flash temperature of (S1) is 40°C, the operating pressure is 1atm, the flash temperature of the second flash tank (S2) is 40°C, and the operati...

Embodiment 2

[0041] Use mixed ionic liquids (take [EMIM][Ac]50%+[EMIM][BF4]50% as an example)

[0042] The feed flow rate of waste gas containing chloromethane is 100kg / h, and the feed contains 8% (mass fraction) of chloromethane, 1% (mass fraction) of water, 0.1% dimethyl ether (mass fraction), and the balance is nitrogen. The number of theoretical plates of the gas absorption tower (T1) is 10, the feeding position of the chloromethane waste gas is the 10th, and the mixed ionic liquid (based on [EMIM][Ac]50%+[EMIM][BF4]50% Example) Feed from the first plate position of the gas absorption tower (T1), the operating pressure and temperature of the gas absorption tower (T1) are 2.5atm and 30°C, the feed quality of the ionic liquid and the waste gas containing chloromethane during the absorption process The ratio is 2:1, the flash temperature of the first flash tank (S1) is 50 °C, the operating pressure is 1 atm, the flash temperature of the second flash tank (S2) is 40 °C, the operating press...

Embodiment 3

[0044] Use a mixture of ionic liquid and water (take [EMIM][Ac]90%+water 10% as an example)

[0045] The feed flow rate of the waste gas containing chloromethane is 100kg / h, the feed contains 6% (mass fraction) of chloromethane, 1% (mass fraction) of water, 0.1% dimethyl ether (mass fraction), and the balance is nitrogen. The number of theoretical plates of the gas absorption tower (T1) is 9, the feeding position of the waste gas containing chloromethane is the 9th, the operating pressure and temperature of the gas absorption tower (T1) are 2atm and 30°C respectively, and the mixture of ionic liquid and water ( Taking [EMIM][Ac]90%+water 10% as an example) feeds from the first plate position of the gas absorption tower (T1), and the feed mass ratio of ionic liquid to chloromethane waste gas in the absorption process is 3: 1. The flash temperature of the first flash tank (S1) is 40°C, the operating pressure is 1 atm, the flash temperature of the second flash tank (S2) is 50°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com