Resource utilization method of copper in etching waste liquid

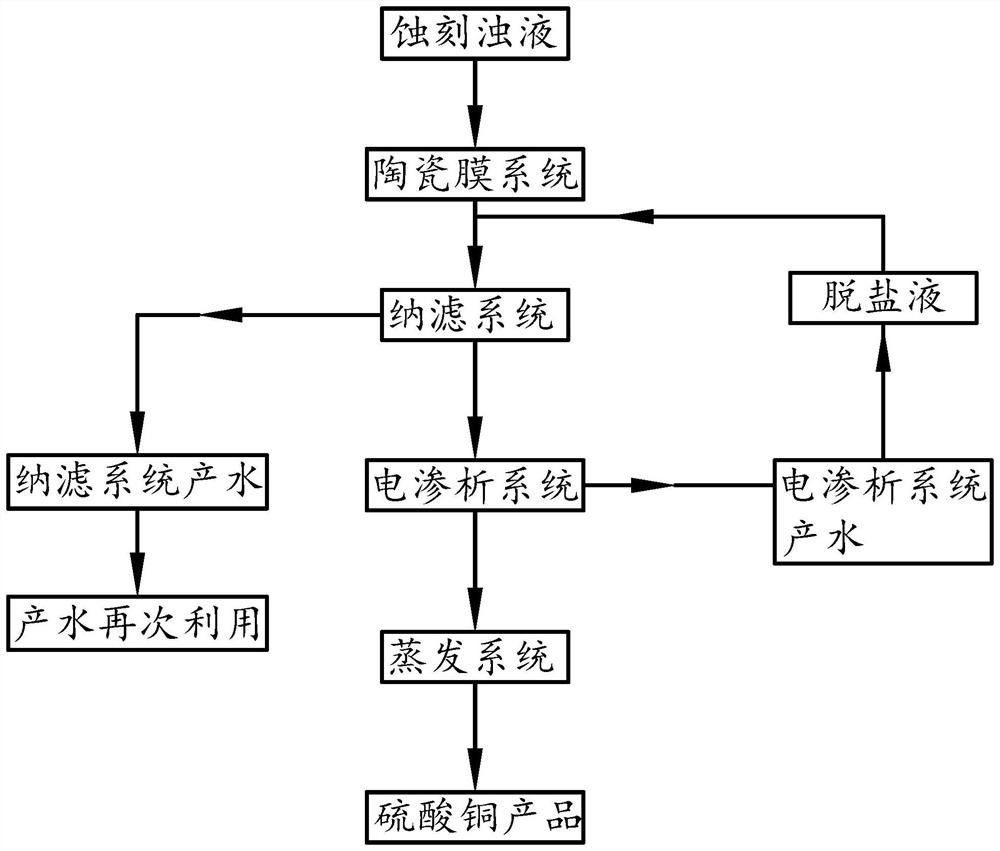

An etching waste liquid, recycling technology, applied in chemical instruments and methods, copper sulfate, water/sewage multi-stage treatment, etc., can solve problems such as waste of copper and environmental pollution, achieve low energy consumption, reduce investment scale, guarantee The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment one: concrete steps are as follows:

[0039] 1) The etching waste liquid is first treated with a ceramic membrane system to remove impurities such as large particles and suspended solids in the waste liquid, and meet the water inlet requirements of the subsequent nanofiltration system. The ceramic membrane has a pore size of 50nm and an operating pressure of 0.1-0.3MPa. The operating temperature is 20-40°C; the specific data are shown in the table below.

[0040] project Copper sulfate (g / L) Turbidity (NTU) Etching waste 0.3 20 Water produced by ceramic membrane 0.3 0.5

[0041] It can be seen from the table that the ceramic membrane system has a good effect on removing impurities such as large particles and suspended solids, and the turbidity of the final system product water is less than 1NTU, which meets the water inlet requirements of the subsequent nanofiltration system and can ensure the stable operation of the system. A...

Embodiment 2

[0049] Embodiment two: concrete steps are as follows:

[0050] 1) The etching waste liquid is first treated with a ceramic membrane system to remove impurities such as large particles and suspended solids in the waste liquid, and meet the water inlet requirements of the subsequent nanofiltration system. The ceramic membrane pore size is 100nm, and the operating pressure is 0.1-0.3MPa. The operating temperature is 20-40°C; the specific data are shown in the table below.

[0051] project Copper sulfate (g / L) Turbidity (NTU) Etching waste 0.5 25 Water produced by ceramic membrane 0.5 0.5

[0052] It can be seen from the table that the ceramic membrane system has a good effect on removing impurities such as large particles and suspended solids, and the turbidity of the final system product water is less than 1NTU, which meets the water inlet requirements of the subsequent nanofiltration system and can ensure the stable operation of the system; At t...

Embodiment 3

[0060] Embodiment three: concrete steps are as follows:

[0061] 1) The etching waste liquid is first treated with a ceramic membrane system to remove impurities such as large particles and suspended solids in the waste liquid, and meet the water inlet requirements of the subsequent nanofiltration system. The ceramic membrane pore size is 20nm, and the operating pressure is 0.1-0.3MPa. The operating temperature is 20-40°C, and the specific data are shown in the table below.

[0062] project Copper sulfate (g / L) Turbidity (NTU) Etching waste 0.45 15 Water produced by ceramic membrane 0.45 0.5

[0063] It can be seen from the table that the ceramic membrane system has a good effect on removing impurities such as large particles and suspended solids, and the turbidity of the final system product water is less than 1NTU, which meets the water inlet requirements of the subsequent nanofiltration system and can ensure the stable operation of the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com