Automobile factory water curtain spraying room circulating wastewater treatment and recycling system and recycling method

A technology for waste water treatment and automobile factory, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. CODCr increase and other problems, to achieve the effect of stable effluent water quality, reduction of organic matter and other pollutant concentrations, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

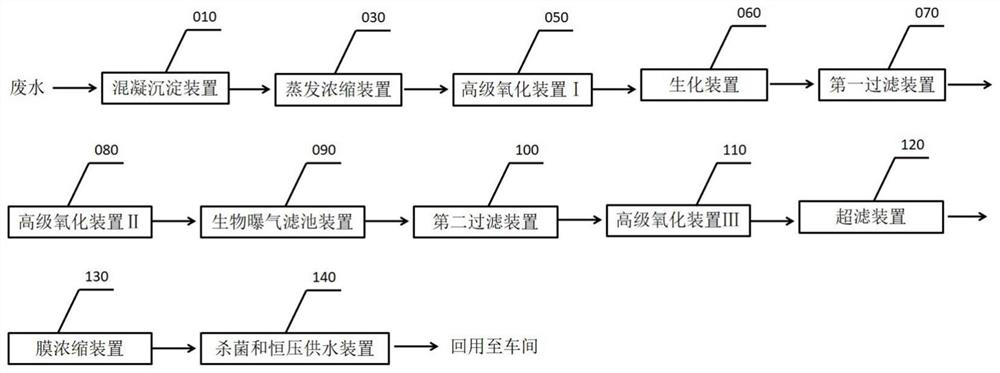

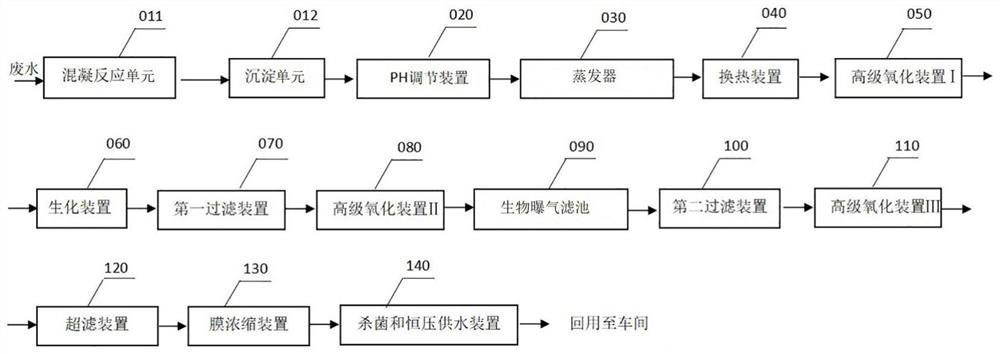

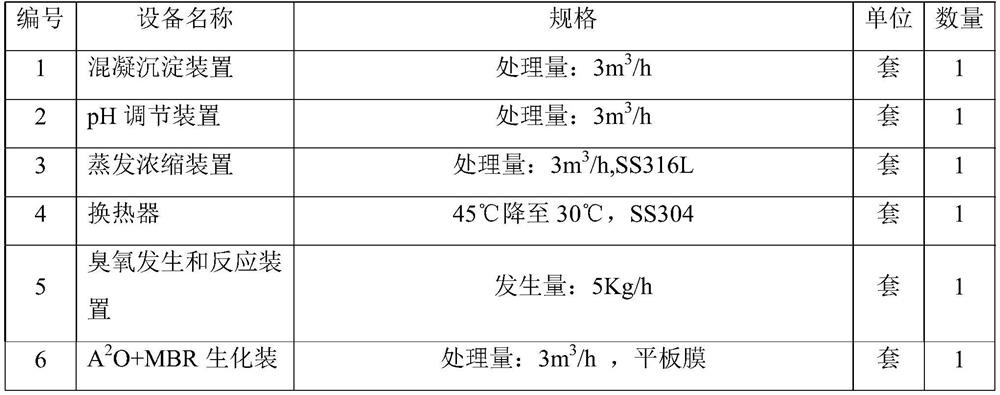

Method used

Image

Examples

Embodiment

[0065] During the automobile painting process of a large-scale joint venture automobile assembly plant in China, the circulating wastewater pool of the water curtain spray room regularly produces wastewater discharge water. The circulating water used to use tap water as a replenishment water source in order to meet the environmental protection requirements for the discharge of this water area (if the excess Exceeding the standard discharge will directly affect the production and operation of the enterprise), build a deep wastewater reuse system, the water quality after treatment can meet the water quality requirements of the water curtain spray room circulating water, if the water is not enough, the original water supply system can be used to make up for it, and the circulating water is passed through The newly-built waste water deep reuse system, that is, the water curtain spray booth circulating waste water treatment and reuse system provided by the present invention, performs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com