Refining method of biapenem crude product

A technology of biapenem and refining method, applied in the field of chemical pharmacy, can solve problems such as troublesome operation, and achieve the effects of small crystal size, high yield and reducing solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

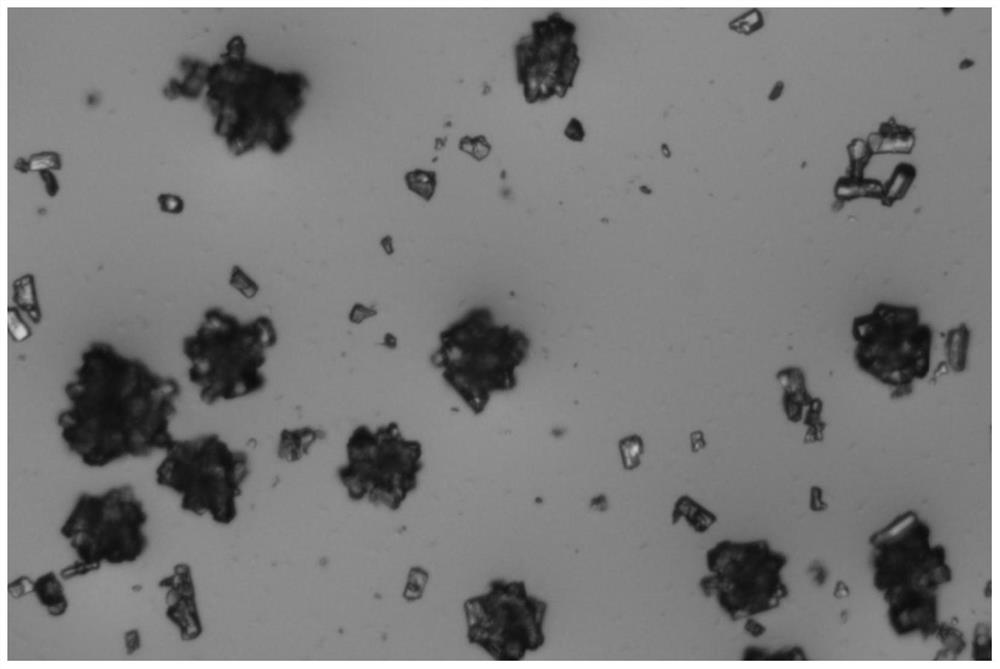

Image

Examples

Embodiment 1

[0044] A method for refining crude biapenem, comprising the steps of:

[0045] 1. Put 3 g of crude biapenem into 100 mL of water for injection (controlled temperature at 25°C), and stir until dissolved to obtain a mixture.

[0046] 2. Add 0.03 g of activated carbon to the mixture, stir and dissolve, then filter to obtain feed liquid; keep the feed liquid temperature at 25°C.

[0047] 3. The feed solution was dropped into 100 mL of ethanol (at a controlled temperature of 5° C.) to obtain a reaction system.

[0048] 4. Raise the temperature of the reaction system to 20°C and keep it; put 7g of crude biapenem into 300mL of water for injection (control temperature 25°C), stir until it dissolves to obtain a mixture; add 0.27g of activated carbon to the mixture, stir to dissolve and filter , to obtain the feed liquid; dropwise add the feed liquid obtained in this step to the reaction system.

[0049] 5. Keep the temperature of the reaction system at 20°C, grow the crystal for 30 m...

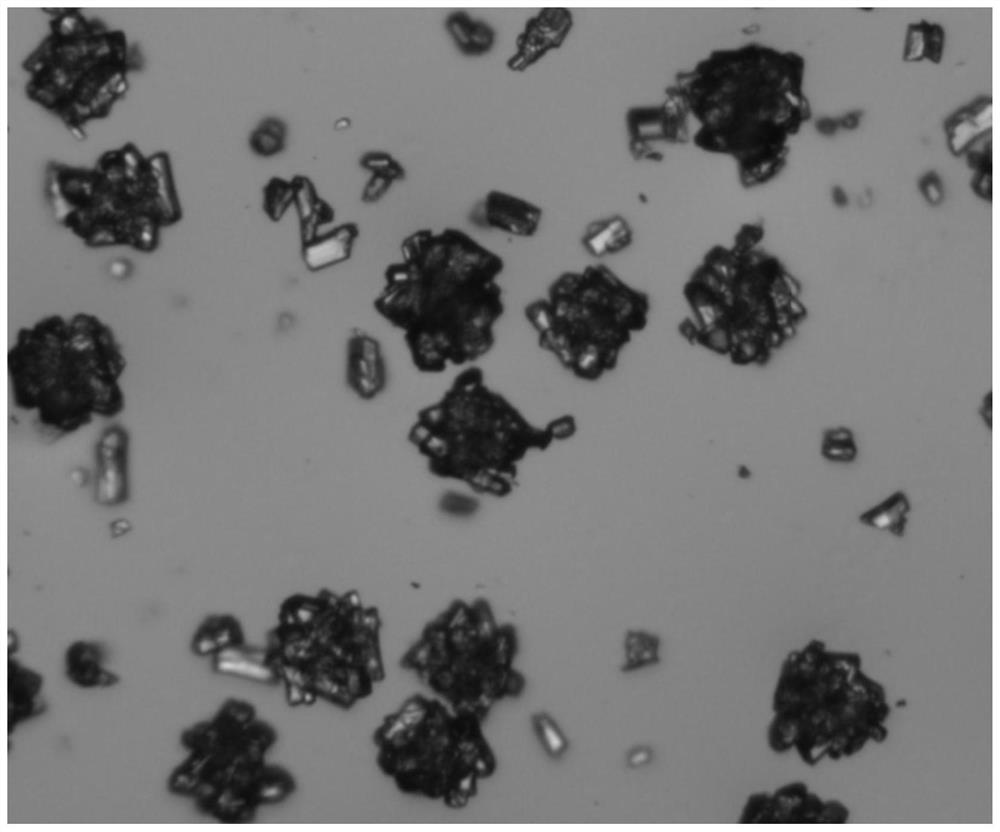

Embodiment 2

[0052] A method for refining crude biapenem, comprising the steps of:

[0053] 1. Put 2 g of crude biapenem into 120 mL of water for injection (controlled temperature at 20°C), and stir until dissolved to obtain a mixture.

[0054] 2. Add 0.05 g of activated carbon to the mixture, stir to dissolve and then filter to obtain the feed liquid; keep the feed liquid temperature at 20°C.

[0055] 3. Drop the feed solution into 960 mL of ethanol (control temperature -4°C) to obtain a reaction system.

[0056] 4. Raise the temperature of the reaction system to 25°C and maintain it; put 8g of crude biapenem into 480mL of water for injection (control temperature 20°C), stir until it dissolves to obtain a mixture; add 0.45g of activated carbon to the mixture, stir to dissolve and then filter , to obtain the feed liquid; dropwise add the feed liquid obtained in this step to the reaction system.

[0057] 5. Keep the temperature of the reaction system at 25°C, grow the crystal for 30 minutes...

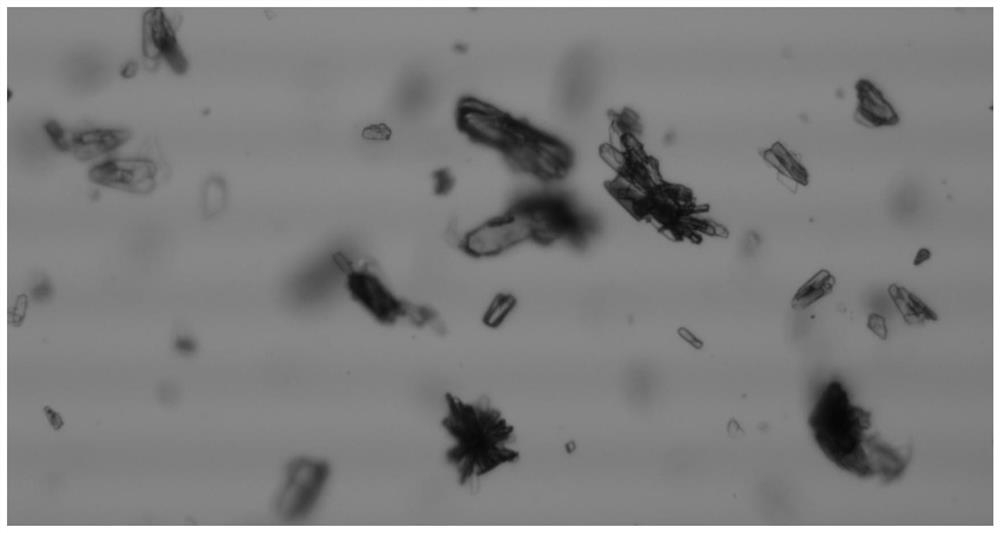

Embodiment 3

[0059] A method for refining crude biapenem, comprising the steps of:

[0060] 1. Put 1 g of crude biapenem into 45 mL of water for injection (at a controlled temperature of 30°C), and stir until dissolved to obtain a mixture.

[0061] 2. Add 0.02 g of activated carbon to the mixture, stir, dissolve and filter to obtain a feed liquid; keep the temperature of the feed liquid at 30°C.

[0062] 3. Drop the feed solution into 1350mL ethanol (control temperature -7°C) to obtain a reaction system.

[0063] 4. Raise the temperature of the reaction system to 15°C and keep it; put 9g of crude biapenem into 405mL of water for injection (control temperature 30°C), stir until the mixture is dissolved; add 0.18g of activated carbon to the mixture, stir to dissolve and then filter , to obtain the feed liquid; dropwise add the feed liquid obtained in this step to the reaction system.

[0064] 5. Keep the temperature of the reaction system at 15°C, grow the crystal for 30 minutes after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com