Preparation method of inverse emulsion, thickening agent and emulsifying agent

An inverse emulsion and emulsifier technology, applied in skin care preparations, cosmetics, pharmaceutical formulations, etc., can solve the problems of non-emulsion emulsification ability disclosure, low operation efficiency, complex process, etc., to achieve emulsified heat storage stability, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

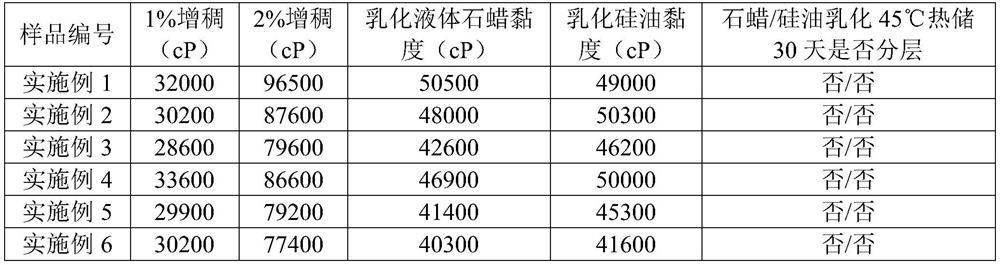

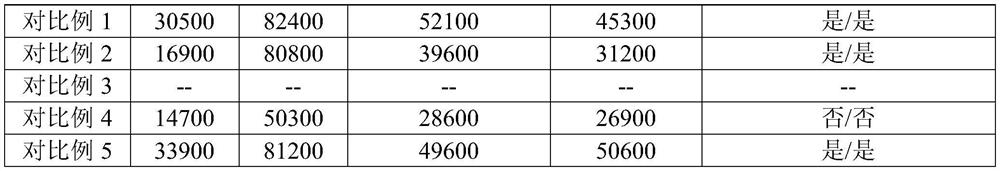

Examples

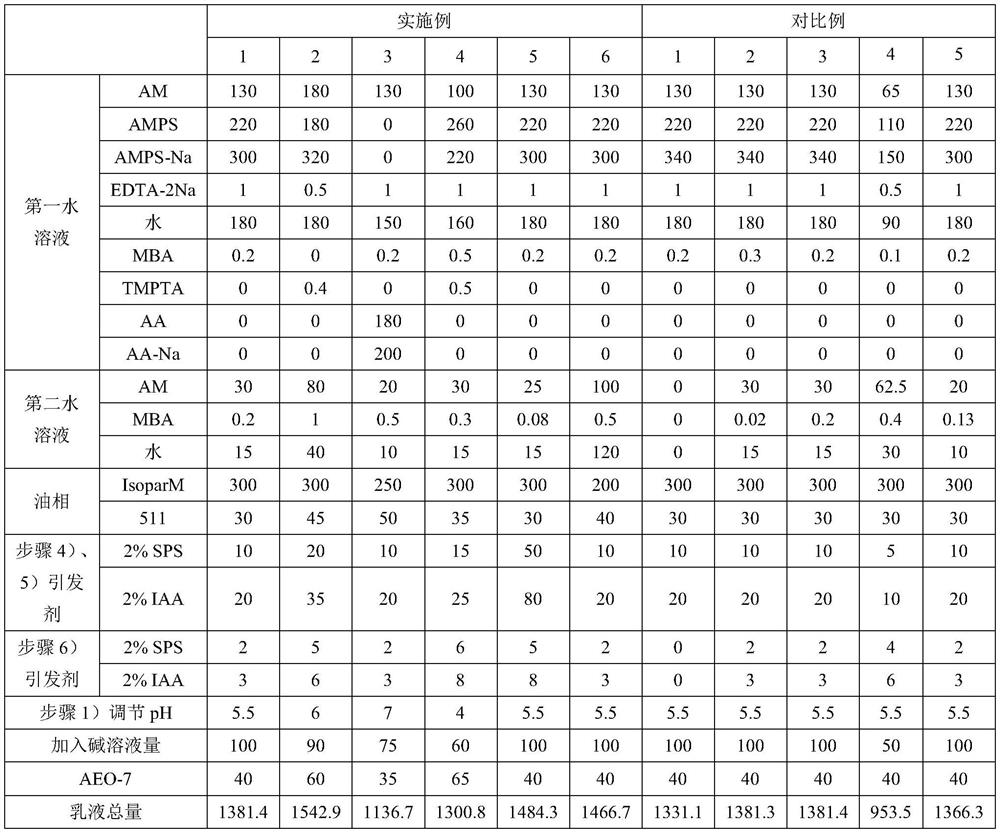

Embodiment 1

[0059] 1) Mix 130g AM, 220g AMPS, 300g AMPS-Na solution, 0.2g MBA, 1g EDTA-2Na, 180g deionized water, neutralize with 50wt% NaOH solution, adjust the pH to 5.5, and obtain the first aqueous solution;

[0060] 2) Mix 13g AM, 0.05g MBA, and 15g deionized water to obtain a second aqueous solution;

[0061] 3) Mix 300g Isopar M and 30g 511 emulsifier, and cool down to 5°C;

[0062] 4) Under stirring conditions, add the aqueous solution of 1) dropwise to the oil phase of 3), add 10 g of 2% SPS aqueous solution at one time, and deoxygenate for 30 minutes;

[0063] 5) 20g of 2% IAA aqueous solution was added dropwise to initiate polymerization, the dropwise addition time was 1h, and the dropwise addition was completed at 70°C for further insulation for 1h;

[0064] 6) Add the second aqueous solution dropwise to the system after the reaction in 5), and according to the above initiation method, add 2g of 2% SPS aqueous solution at one time, remove oxygen for 15 minutes, add dropwise 3...

Embodiment 2-4

[0067] Carry out according to the operation of embodiment 1, relevant material consumption is as shown in table 1.

Embodiment 5

[0069] With the amount of materials in Table 1, carry out according to the following process conditions:

[0070] In step 1), adjust the pH of the first aqueous solution to 7; in step 3), control the temperature of the oil phase to 15°C; in step 5), the time for adding the reducing agent to the first aqueous solution is 2 hours; The temperature is 40° C.; all the other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com