Preparation method of PVA double-crosslinking hydrogel based on 2d resin

A hydrogel and double-crosslinking technology, which is applied in the field of preparation of PVA double-crosslinked hydrogels, can solve problems such as insufficient toughness, uncontrollable crosslinking degree, and restrictions on the practical application of PVA hydrogels, and achieve simple and easy process line, enhance the effect of mechanical strength and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

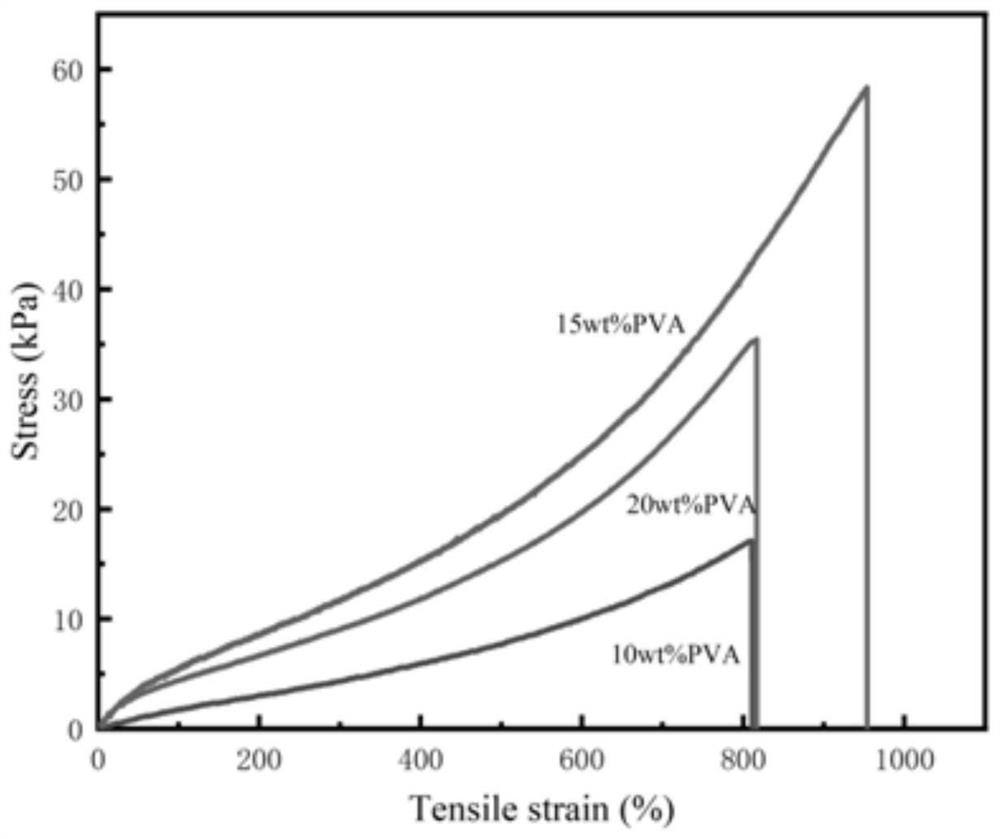

Embodiment 1

[0031] Step 1: Add 1 g, 1.5 g, and 2 g of polyvinyl alcohol (PVA) to 9 g, 8.5 g, and 8 g of deionized water respectively, and add 0.05 g of citric acid and 0.1 g of magnesium chloride to the three solutions , stirring at 95°C for 2 hours, until the PVA is completely dissolved to form a uniform mass concentration of 10wt%, 15wt% and 20wt% PVA mixed solution;

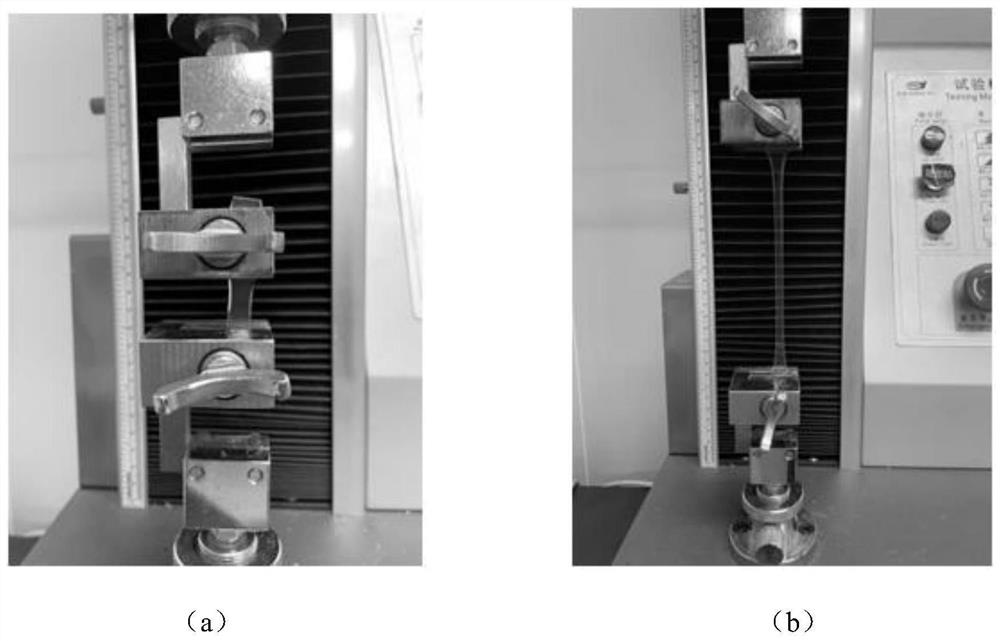

[0032] Step 2: Place the PVA mixed solutions of three different mass concentrations prepared in step 1 in three beakers respectively, add 0.5 ml of 2d resin and 20 microliters of polyvinyl alcohol defoamer in each beaker, Stir vigorously by hand with a glass rod for 10 minutes at room temperature, then transfer to a mold, and let it stand at room temperature for 2 days. After the bubbles are completely eliminated, heat it in an oven at 80°C for 4 hours to obtain PVA / 2d SN with different PVA mass concentrations.

[0033] Step 3: Prepare a saturated borax solution, put PVA gels of different mass concentrations into and soak...

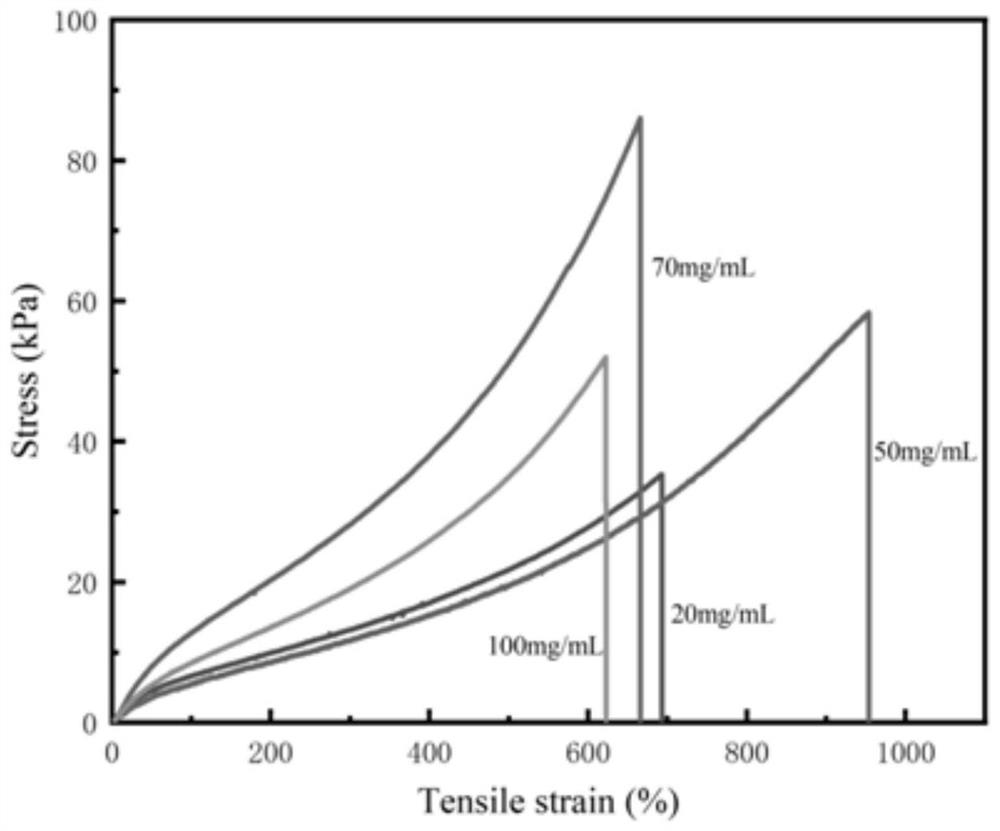

Embodiment 2

[0035] Step 1: Add 1.5 grams of polyvinyl alcohol to 8.5 grams of deionized water, add 0.05 grams of citric acid and 0.1 grams of magnesium chloride, and stir at 95°C for 2 hours until the PVA is completely dissolved to form a uniform mass concentration of 15wt % PVA mixed solution;

[0036] Step 2: Take the PVA mixed solution of step 1 and place them in four beakers respectively, add 20 microliters of polyvinyl alcohol defoamer to the above four beakers, and then add 0.2 ml, 0.5 ml, 0.7 ml and 1 ml respectively The 2d resin was stirred vigorously by hand with a glass rod for 10 minutes at room temperature, then transferred to a mold, and left to stand at room temperature for 2 days. After the air bubbles were completely eliminated, it was heated in an oven at 80°C for 4 hours to obtain single-layer resins with different 2d resin concentrations. Cross-linked network hydrogels;

[0037] Step 3: prepare a saturated borax solution, put the single-crosslinked network hydrogels co...

Embodiment 3

[0039] Step 1: Add 1.5 grams of polyvinyl alcohol to 8.5 grams of deionized water, add 0.05 grams of citric acid and 0.1 grams of magnesium chloride, and stir at 95°C for 2 hours until the PVA is completely dissolved to form a uniform mass concentration of 15wt % PVA mixed solution;

[0040] Step 2: Take the PVA mixed solution and place it in a beaker, add 0.5 ml of 2d resin and 20 microliters of polyvinyl alcohol defoamer into the beaker, stir vigorously with a glass rod at room temperature for 10 minutes, and then transfer it to a mold. Stand at room temperature for 2 days, and after the air bubbles are completely eliminated, heat in an oven at 80°C for 4 hours to obtain a network hydrogel (PVA / 2d SN) in which PVA is single-crosslinked by 2d resin;

[0041] Step 3: Prepare a saturated borax solution, put the obtained PVA gel into and soak for 30s, 60s, 70s, 90s and 110s respectively, and obtain four parts of the target product PVA / 2d DN hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com