Solid solution device and method for improving strength and plasticity of in-situ synthesis aluminum matrix composite

An aluminum matrix composite material, an in-situ self-generating technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of low heat treatment efficiency, slow thermal radiation heat transfer rate, and insufficient uniformity and stability of thermal field temperature, and achieves the Effects of grain growth, shortening of solution time, and increased elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

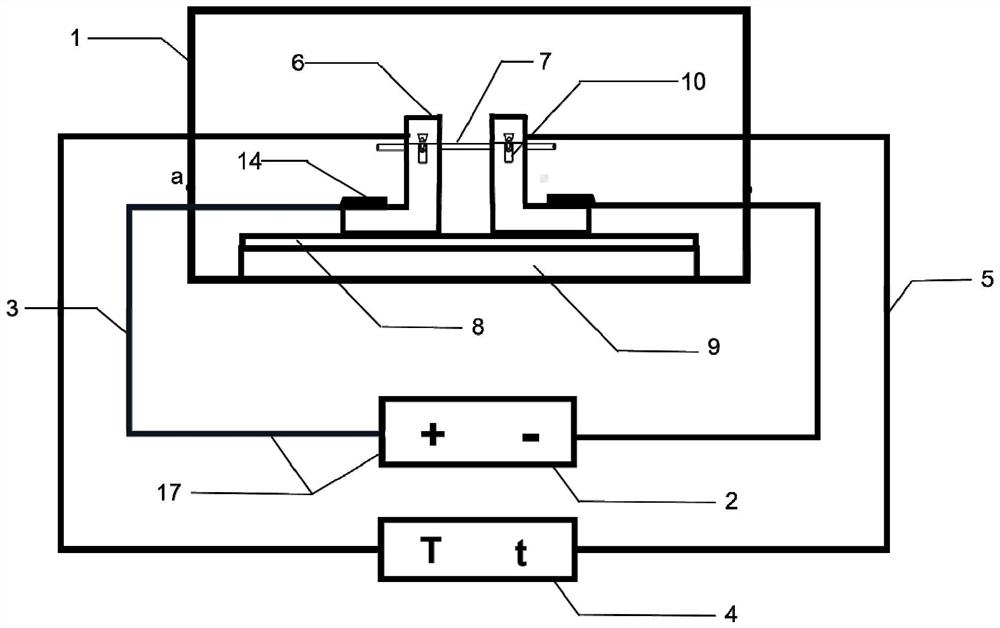

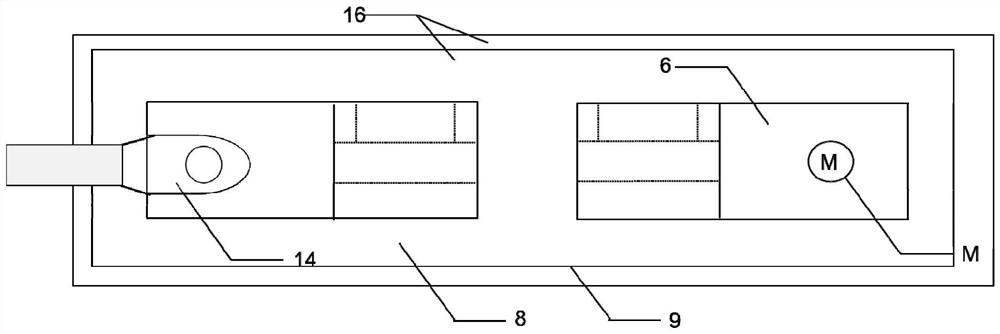

[0039] For extruded 3wt% TiB 2 / Al-Zn-Mg-Cu composite material is subjected to electric pulse assisted solid solution treatment, the specific steps are:

[0040] Step 1: Turn on the solid solution furnace 1, raise the temperature to the target temperature of 455°C±5°C, turn on the digital thermometer switch 4 to record the temperature change with time, keep it warm for 10 minutes, until the digital thermometer 4 displays the temperature and the solid solution furnace 1 set temperature same;

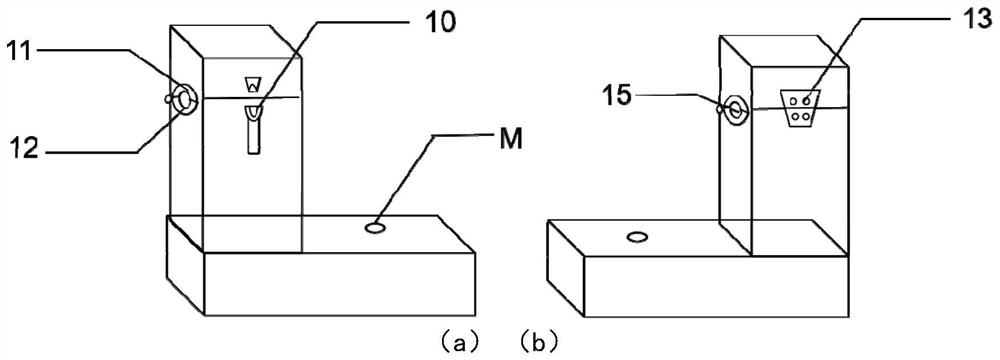

[0041] Step 2, put the sample 7 into the L-shaped copper fixture sample table 15, fasten the buckle 10, close the furnace door of the solution furnace 1 until the temperature returns to 455°C, and the process takes 2 to 3 minutes;

[0042] Step 3, turn on the pulse power supply 2 water cooling box to achieve heat dissipation effect, the voltage is 10.4V ~ 22V, the pulse form is bidirectional pulse, the duty cycle is 50%, adjust the pulse current 100A, pulse frequency 60Hz, power-on time ...

example 2

[0048] For extruded 3wt% TiB 2 / Al-Zn-Mg-Cu composite material is subjected to electric pulse assisted solid solution treatment, the specific steps are:

[0049] Step 1: Turn on solid solution furnace 1, raise the temperature to the target temperature of 455°C±5°C, turn on the digital thermometer 4 switch to record the temperature change with time, keep warm for 10 minutes, until the digital thermometer 4 displays the temperature and the solid solution furnace 1 set temperature same;

[0050] Step 2, put the sample 7 into the L-shaped copper fixture sample table 15, fasten the buckle 10, close the furnace door of the solution furnace 1 until the temperature returns to 455°C, and the process takes 2 to 3 minutes;

[0051] Step 3, turn on the pulse power supply 2 water cooling box to achieve heat dissipation effect, the voltage is 10.4V ~ 22V, the pulse form is bidirectional pulse, the duty cycle is 50%, adjust the pulse current 100A, pulse frequency 500Hz, power-on time 30min,...

example 3

[0057] For extruded 3wt% TiB 2 / Al-Zn-Mg-Cu composite material is subjected to electric pulse assisted solid solution treatment, the specific steps are:

[0058] Step 1: Turn on solid solution furnace 1, raise the temperature to the target temperature of 455°C±5°C, turn on the digital thermometer 4 switch to record the temperature change with time, keep warm for 10 minutes, until the digital thermometer 4 displays the temperature and the solid solution furnace 1 set temperature same;

[0059] Step 2, put the sample 7 into the L-shaped copper fixture sample table 15, fasten the buckle 10, close the furnace door of the solution furnace 1 until the temperature returns to 455°C, and the process takes 2 to 3 minutes;

[0060] Step 3, turn on the pulse power supply 2 water cooling box to achieve heat dissipation effect, the voltage is 10.4V ~ 22V, the pulse form is bidirectional pulse, the duty cycle is 50%, adjust the pulse current 200A, pulse frequency 200Hz, power-on time 30min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com