Ultralow-temperature liquefied gas pressure vessel for improving heat insulation effect

A technology for liquefied gas and pressure vessels, which is applied to non-pressure vessels, container filling methods, container discharge methods, etc., can solve the problems of insufficient use of cooling capacity and affect the thermal insulation effect of ultra-low temperature liquefied gas pressure vessels, and improve the thermal insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

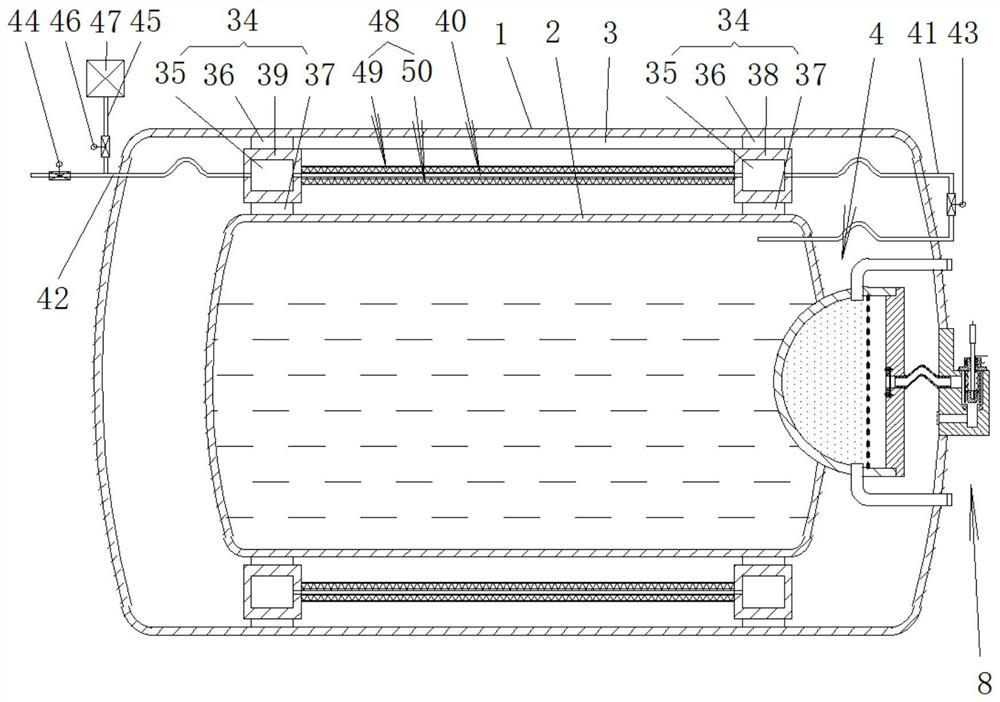

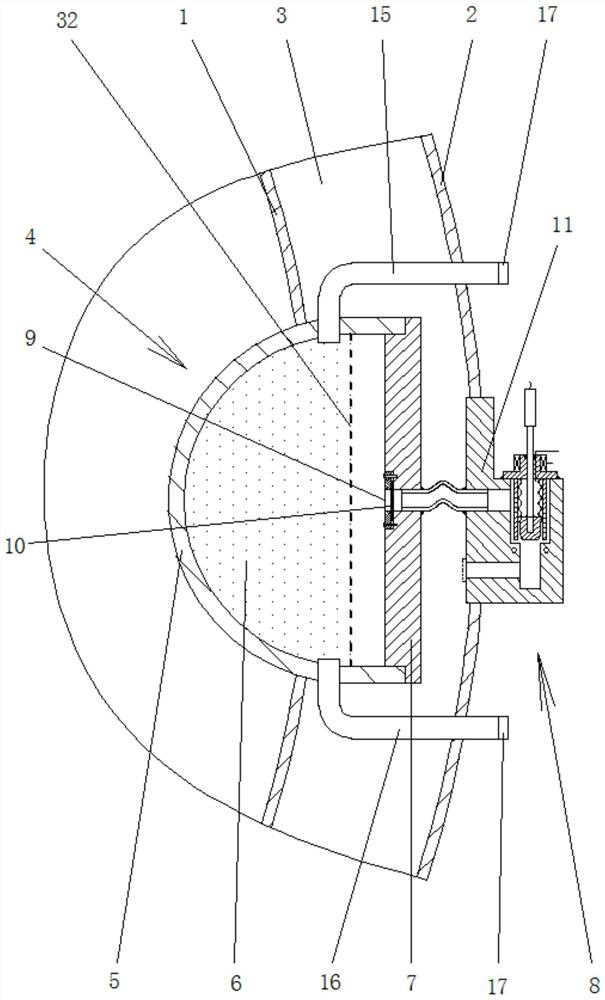

[0040] Such as Figure 1 to 7 The exemplary embodiment of the present invention is an ultra-low temperature liquefied gas pressure vessel for increasing the heat insulating effect, including the insulator 1, the outer container 2, formed in a sandwich space between the insulator 1 and the outer container 2. 3. Supporting the support assembly 34 between the instructor 1 and the outer container 2, the support assembly 34 includes a pair of support loops 38, 39 with an annular hollow internal cavity 35, disposed in the support ring. 38, 39 The number of several numbers arranged along the circumferential intervals is used to support the outer support of the outer wall of the outer container 2, which is disposed in the support ring 38, 39, and several quantities arranged along the circumferential interval for support. The inside support of the outer wall of the contentor 1; the pair of support ring 38, 39 includes a first support ring 38 and a second support ring 39, and the annular hol...

Embodiment 2

[0057] The replaceable molecular sieve adapter in the above Example 1 adopts the following structure:

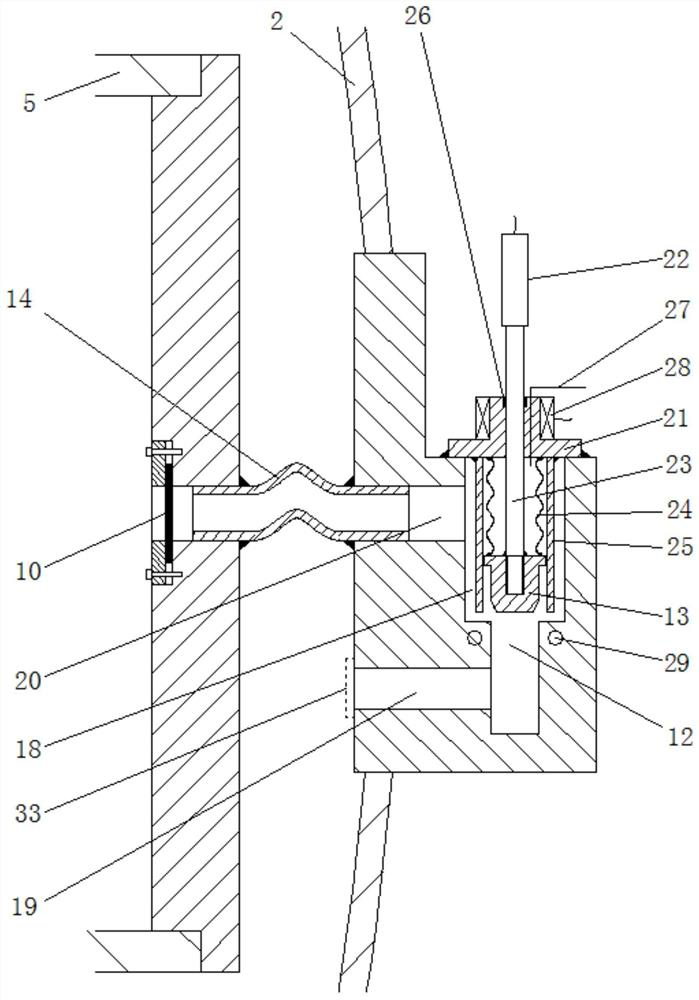

[0058] The molecular sieve adapter 4 includes a molecular sieve sucking case 5 disposed on the inscribed 1 tank, which is filled inside the molecular sieve adsorbed casing 5 for adsorbing a molecular sieve 6 of the inner gas and moisture of the clamping space 3, provided in The molecular sieve sucking cassette 5 is configured to enclose the molecular sieve 6 in the casing 7 in the inside of the molecular sieve suction case 5, a vacuum environment for a vacuum environment on the outer container 2 tank 8, the box A adsorbed hole 9 is provided on the cover 7, and the adsorbent hole 9 is provided with a blanked sealing sheet 10 which includes a valve body 11 and an adsorbent passage disposed on the valve body 11. The vacuum sealing hole 12 is disposed on the adsorption passage, which is provided on the vacuum sealing hole 12 for blocking or opening the thermal expansion sealing plun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap