Sulfuration-resistant conductor paste

A kind of conductor paste, vulcanization-resistant technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc. The effect of simple preparation process and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

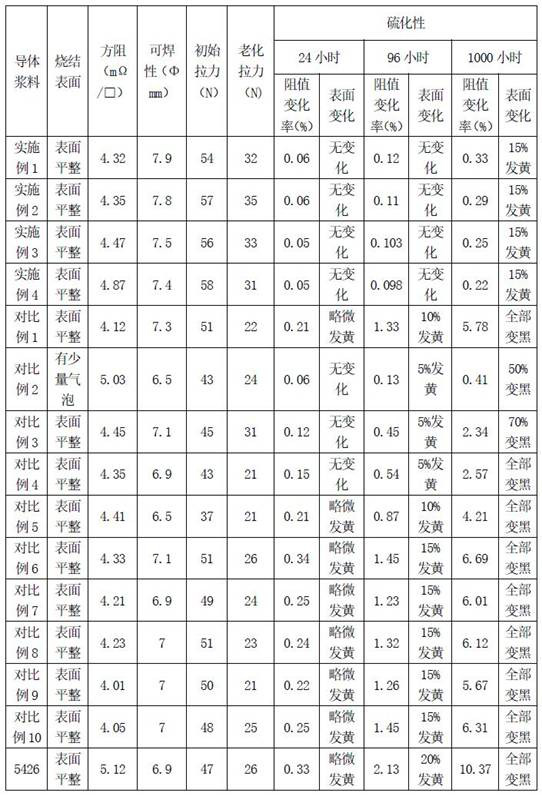

Examples

Embodiment Construction

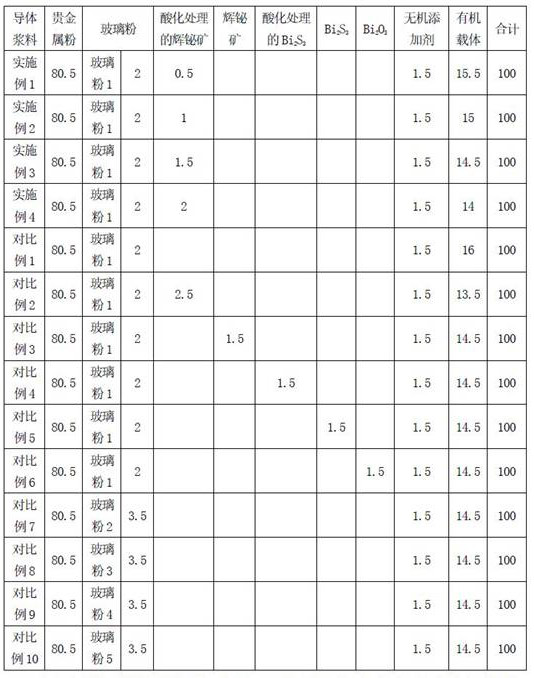

[0016] The present invention will be described in detail below in conjunction with specific examples, which do not limit the protection scope of the present invention. The protection scope of the present invention is only limited by the claims, and any omission, replacement or modification made by those skilled in the art on the basis of the disclosed embodiments of the present invention will fall within the protection scope of the present invention.

[0017] 1. Selection of precious metal powder: select silver powder with a particle size of 1.2-1.3 μm and a specific surface area of 12-15 m 2 / g of palladium powder, the specific surface area is 10 ~ 12m 2 / g of platinum powder, silver powder, palladium powder, and platinum powder are mixed in a weight ratio of 78:2:0.5 as precious metal powder.

[0018] 2. Preparation of acidified bismuthite: Soak the bismuthite with a particle size of 0.7-1.3 μm in dilute sulfuric acid with a mass concentration of 1% for 30 minutes, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com