Ag-based alloy target material and preparation method thereof

A technology based on alloys and targets, applied in the field of silver-based alloys, can solve problems such as increased resistivity and reduced reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] Example Preparation of Ag-based alloy target

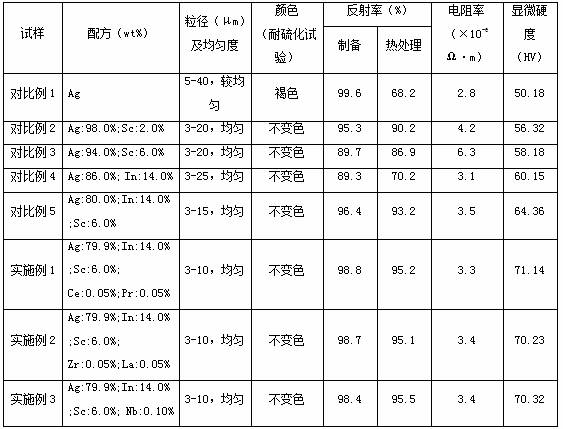

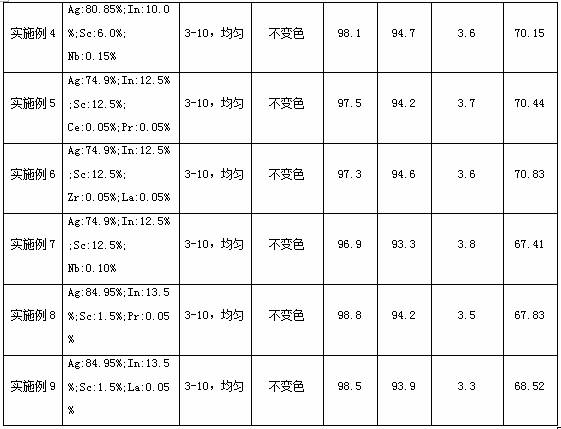

[0084] Recipe: See Table 1 above for details.

[0085] Preparation:

[0086] S1 Melting and ingot casting: Weigh each raw material according to the formula, put it into the crucible of the water-cooled crucible magnetic levitation melting furnace, evacuate to -0.08MPa, fill it with Ar gas until the pressure is 0, keep the pressure for 30s, and repeatedly pump three times; Frequency power supply, gradually increase the heating power, starting from 2.5kw, increase by 0.5kw every 2min, until a continuous flowing spherical molten metal appears in the crucible, increase by 1kw every 1min, when it reaches 9kw, stop increasing the heating power, Keep warm for 8 minutes, let cool, take out the rough ingot; put the rough ingot into the crucible again, repeat the above melting process 1-3 times;

[0087] During the last smelting, after the heat preservation is over, the smelted liquid is injected into the carbonaceous casting mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com