Flaky silver-palladium powder as well as preparation method and application thereof

A silver-palladium powder and flake technology, which is applied in the field of flake silver-palladium powder and its preparation, can solve the problems of silver paste loss of electrical conductivity, ion migration, etc., and achieve the reduction of holes, uniform particle size, and optimized dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

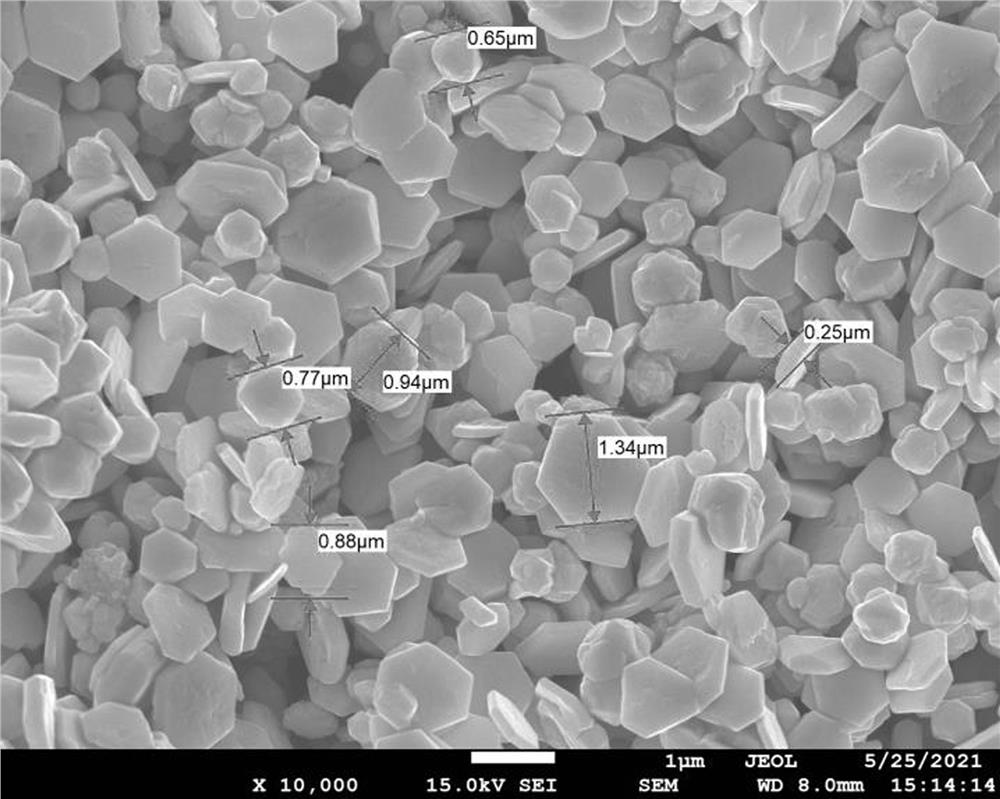

Embodiment 1

[0039] The method for the preparation of the flaky silver-palladium powder of the present embodiment, concrete implementation steps are as follows:

[0040] (1) Preparation of reducing agent solution A: first add 1L of deionized water into the container, then add 1.2g of carboxymethyl cellulose, stir at high speed until the powder is completely dissolved, add 150g of vitamin C, stir and dissolve completely, and prepare a reducing agent solution A, the temperature is controlled at 20-50°C;

[0041] (2) Preparation of silver-containing palladium solution B: the configuration concentration is 0.6mol / L silver nitrate solution, after adding the palladium nitrate solution with a concentration of 0.035mol / L, the mass ratio of silver to palladium is = 10: 1, stirring is completely miscible, The volume of the solution is 1L, and it is configured as a solution B containing silver and palladium, and the temperature is controlled at 20-50°C;

[0042] (3) Prepare the bottom solution C: fi...

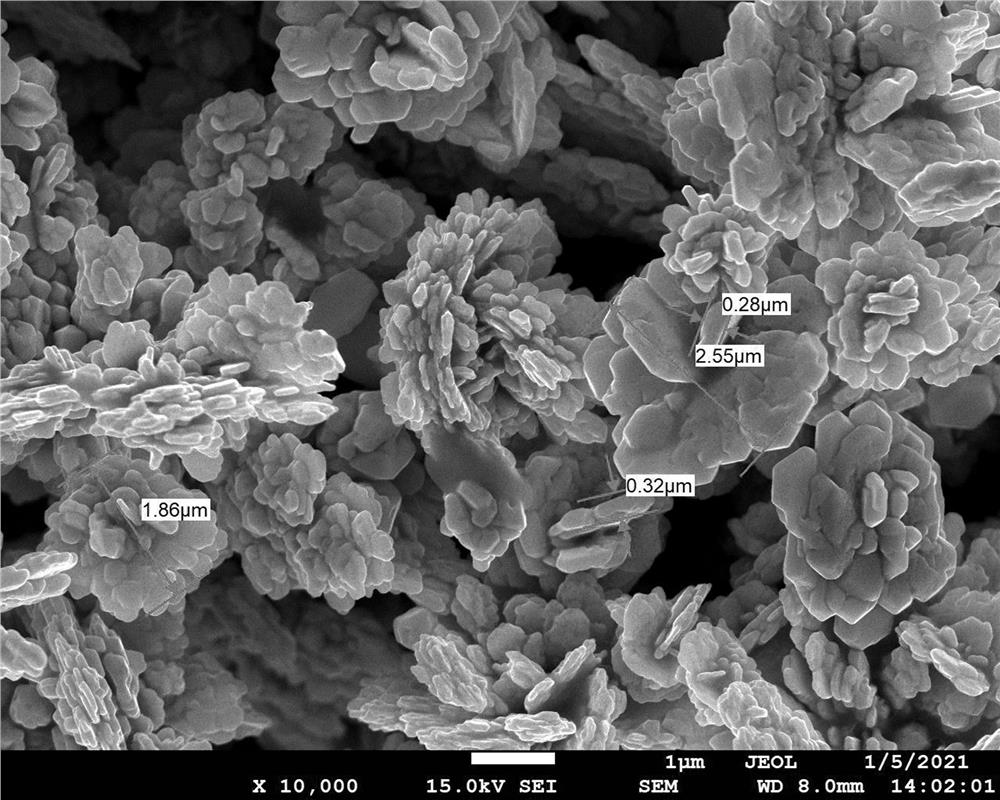

Embodiment 2

[0050] In order to verify the impact of palladium nitrate on the final product in this embodiment, in the preparation process, the silver nitrate solution of the same quality was used to replace the mixed solution of silver nitrate and palladium nitrate. Such as figure 2 As shown, the silver powder physical properties are as follows:

[0051] Table two does not add the physical property of the prepared silver powder of palladium nitrate

[0052]

[0053] Depend on figure 2 As can be seen from the data in Table 2, the present embodiment only uses silver nitrate solution to obtain silver powder, but cannot obtain silver palladium powder. The problem of ion migration still exists in pure silver powder. Silver paste.

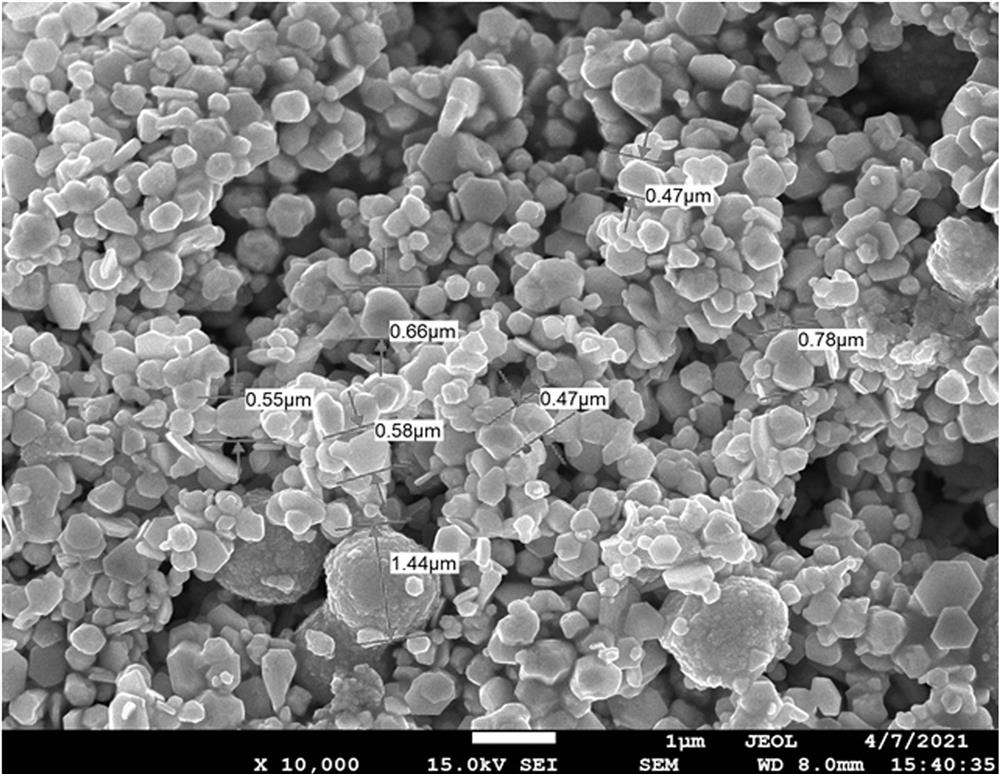

Embodiment 3

[0055] In order to verify the use of carboxymethyl cellulose as a dispersant in this embodiment, the impact on the preparation of silver palladium powder is carried out as follows:

[0056] Experimental group 1: in the preparation process, gelatin is used instead of carboxymethyl cellulose as a dispersant, and its component is the same as that of carboxymethyl cellulose. Other preparation processes and component consumption are the same as in Example 1. The silver palladium powder particles obtained are as follows: image 3 shown.

[0057] Experimental group 2: in the preparation process, carboxymethyl cellulose is not added, and other preparation processes and component consumption are the same as in Example 1, and the obtained silver palladium powder particles are as follows: Figure 4 shown.

[0058] according to image 3 with Figure 4 It can be seen that gelatin does not have a good dispersion effect as a dispersant, image 3 There is agglomeration phenomenon in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com