Saturated deposition process of graphite boat

A deposition process and graphite boat technology, applied in the field of solar cells, can solve the problems of bad cells, affecting production efficiency, and difficult to remove hard shells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it by referring to the description, and the protection scope of the present invention is not limited to the specific embodiments.

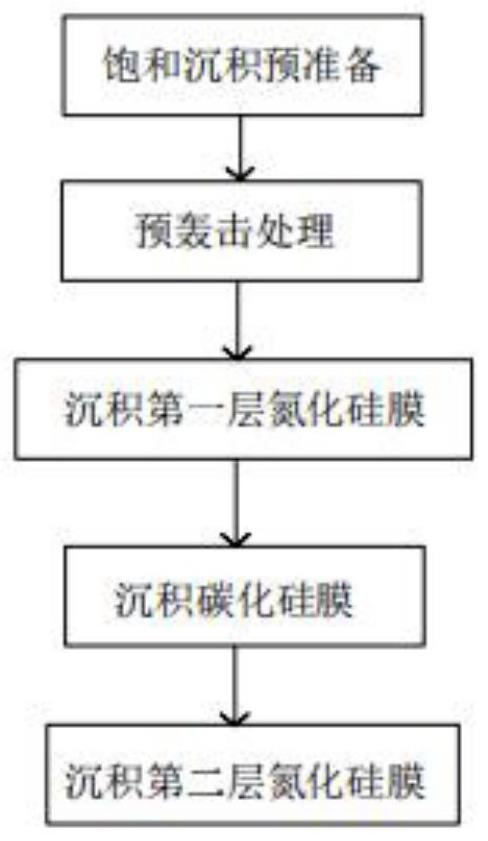

[0018] The present invention relates to a kind of saturated deposition technique of graphite boat, comprises the following steps:

[0019] S1. Put the cleaned graphite boat into the furnace tube for pre-preparation of saturated deposition; the pre-preparation process conditions are: the temperature in the furnace tube is kept at 400-430°C, the pressure is maintained at 1800-2000mTor, nitrogen is used for purging, and the nitrogen flow rate is 8-10slm, the pre-preparation time for saturated deposition is 1400s; in the specific implementation process, it is preferred to use: constant temperature to 420°C, pressure maintained at 2000mTor, nitrogen flow rate 10slm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com