Condensed aerosol fire extinguishing agent as well as preparation method and application thereof

A technology of fire extinguishing agent and sol, applied in the field of hot aerosol fire extinguishing agent and its preparation, can solve the problems of poor conductivity and corrosion resistance, short circuit of electrical equipment, secondary damage, etc., and achieve the effect of good extinguishing performance and increasing combustion thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The present invention also provides the preparation method of above-mentioned thermal aerosol fire extinguishing agent, comprises the steps:

[0071] mixing the oxidizing agent, the reducing agent and the passivating agent in parts by weight to prepare a solid mixture;

[0072] dissolving the binder in a solvent to prepare a liquid mixture;

[0073] adding the liquid mixture to the solid mixture for mixing, and granulating to prepare wet granules;

[0074] The wet granules are dried and pressed to form a hot aerosol fire extinguishing agent.

[0075] In one example, in the press molding step, the pressure is 5-10 MPa. Further, the compression molding pressure includes but not limited to: 5MPa, 6MPa, 7MPa, 8MPa, 9MPa, 10MPa. It can be understood that the compression molding can adopt dual-mode bi-directional cold compression molding, and the temperature of the compression molding is room temperature.

[0076] Further, the preparation method of thermal aerosol fire ex...

Embodiment 1

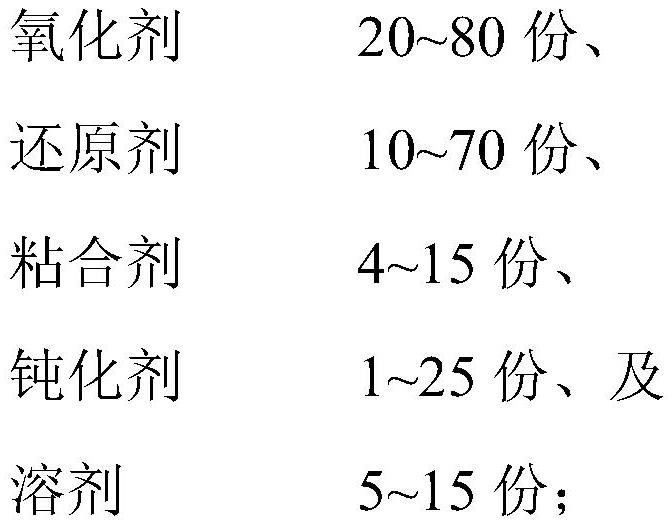

[0088] The present embodiment provides a kind of thermal aerosol fire extinguishing agent, and its raw material composition is as follows:

[0089]

[0090] The preparation method is as follows:

[0091] (1) Premix ammonium nitrate, ammonium dihydrogen phosphate, and basic magnesium carbonate after drying and weighing in proportion, and then pass through a 100-mesh standard sieve to mix evenly after premixing to obtain a solid mixture;

[0092] (2) Dissolving the phenolic resin in ethanol, adding it to the solid mixture obtained in step (1) after dissolving completely, mixing evenly and sieving and granulating with a 20-mesh standard sieve to obtain wet granules;

[0093] (3) Dry the wet granules obtained in step (2) in a constant temperature and humidity environment with a temperature of 35°C and a humidity lower than 50% until the solvent content in the medicament is lower than 1%, and weigh it at a pressure of 5 MPa after reaching the requirements Under the double-mode ...

Embodiment 2

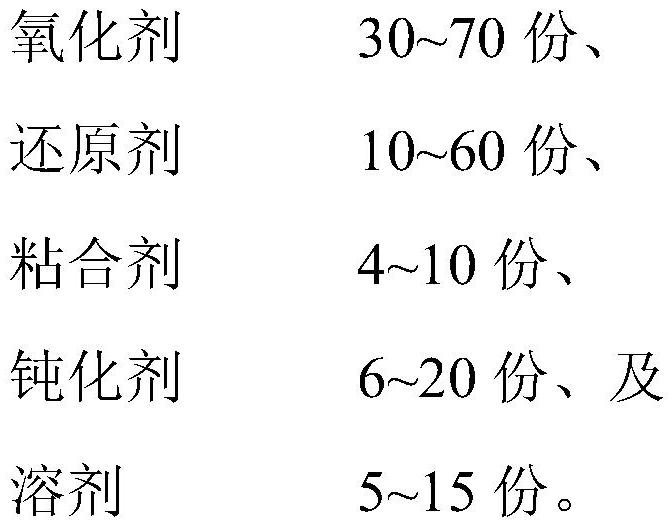

[0095] The present embodiment provides a kind of thermal aerosol fire extinguishing agent, and its raw material composition is as follows:

[0096]

[0097] The preparation method is as follows:

[0098] (1) Strontium nitrate, phosphorus pentanitride, basic magnesium carbonate are dried and premixed after being weighed in proportion, and then mixed evenly through a 100-mesh standard sieve after premixing to obtain a solid mixture;

[0099] (2) Dissolving the phenolic resin in ethanol, adding it to the solid mixture obtained in step (1) after dissolving completely, mixing evenly and sieving and granulating with a 20-mesh standard sieve to obtain wet granules;

[0100] (3) Dry the wet granules obtained in step (2) in a constant temperature and humidity environment with a temperature of 35°C and a humidity lower than 50% until the solvent content in the medicament is lower than 1%, and weigh them at a pressure of 6 MPa after reaching the requirements Under the double-mode two-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com