Diaphragm for lithium ion battery as well as preparation method and application of diaphragm

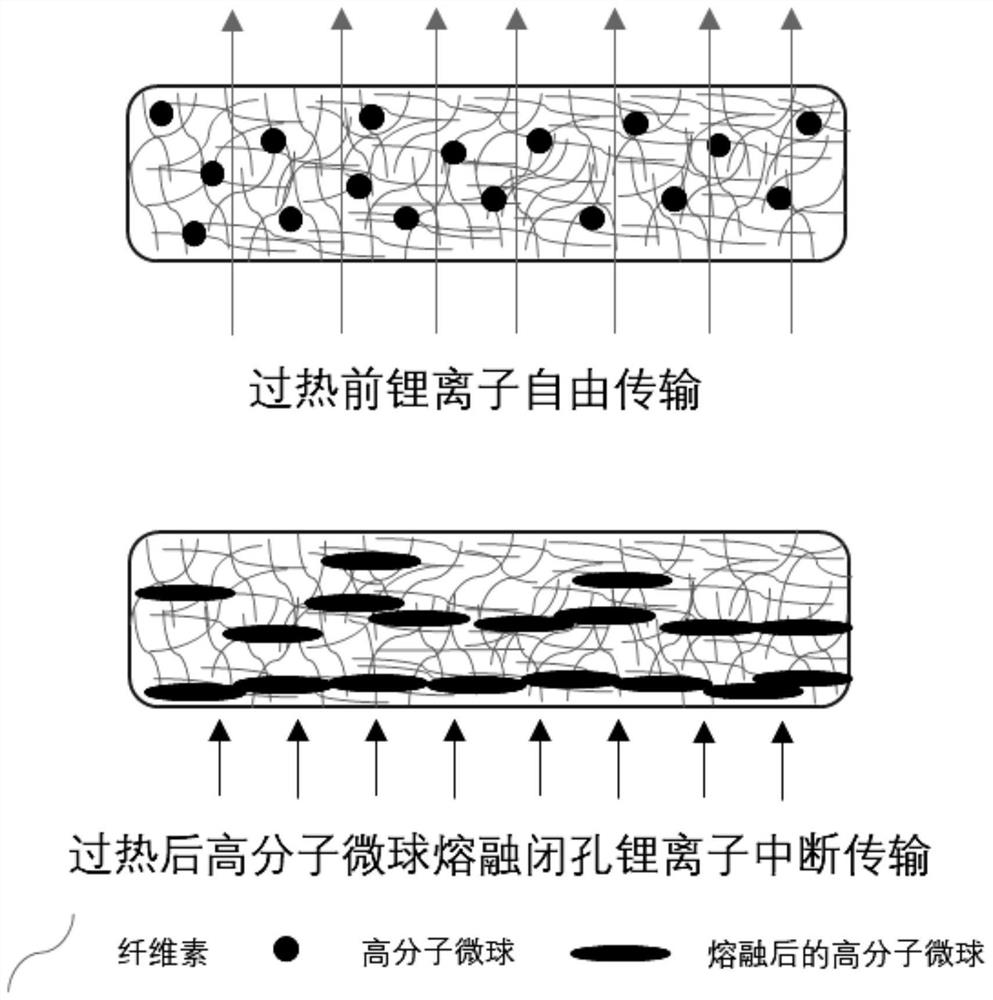

A technology for lithium-ion batteries and diaphragms, applied in the field of diaphragms for lithium-ion batteries and their preparation, can solve the problems of complex diaphragm preparation process, low diaphragm rupture temperature, and safety risks, so as to improve electrochemical performance and interface performance , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second aspect of the present invention is to provide the preparation method of the diaphragm, comprising the following steps:

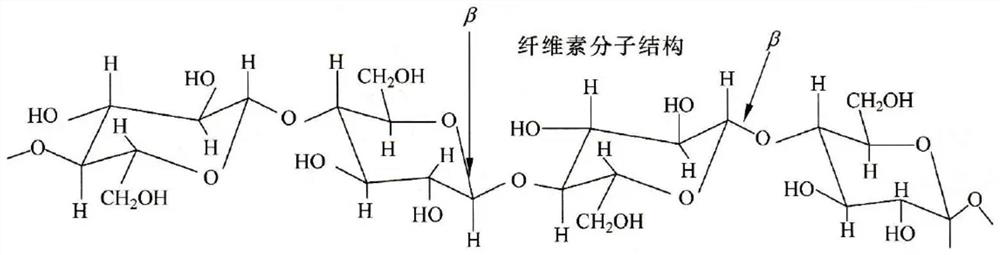

[0039] S1, mixing cellulose with solvent water and ball milling to obtain a nanocellulose solution;

[0040] S2. Mixing and stirring the polymer microspheres and the nanocellulose solution to obtain a mixed solution, wherein the mass ratio of the nanocellulose to the polymer microspheres is 6:4 to 8.5:1.5;

[0041] S3. The mixed solution is freeze-dried and rolled to obtain a separator for a lithium-ion battery.

[0042] Due to the viscosity problem of the nanocellulose solution, the total solid content of the slurry designed by this preparation method is 5-15%. On the one hand, it can avoid the low solid content and it is difficult to meet the coating thickness requirement, and on the other hand, it can avoid the high solid content. This leads to the problems of high viscosity, poor leveling of coating slurry, and uneven film surface.

...

Embodiment 1

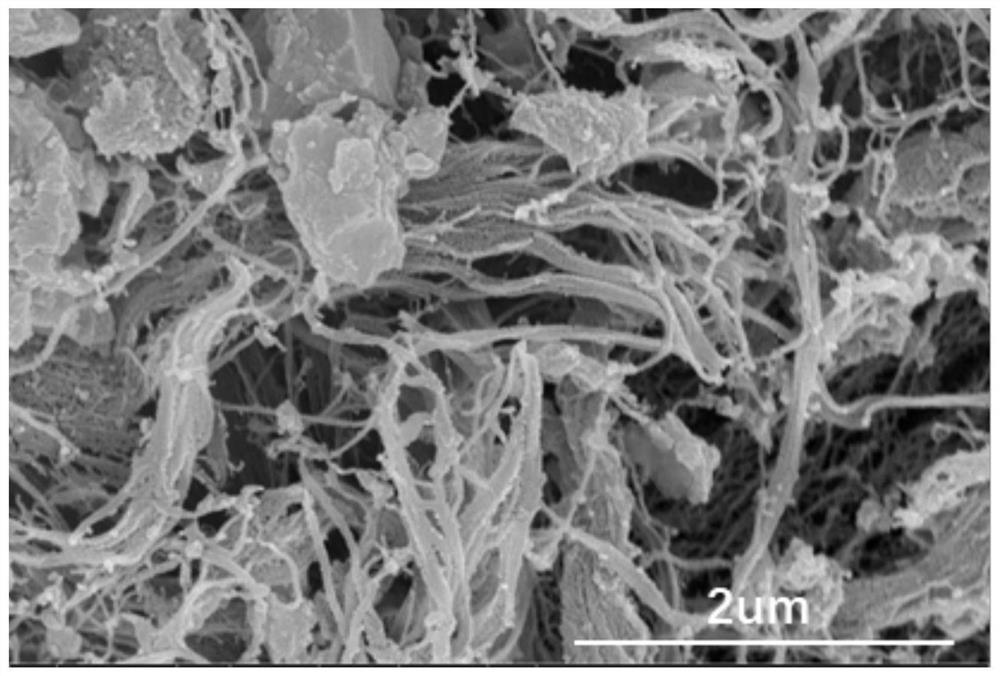

[0054] A separator for a lithium ion battery, comprising nanocellulose and polymer microspheres with a mass ratio of 6:4 to 8.5:1.5, wherein the particle diameter of the polymer microspheres is 0.1 to 3 μm, and the polymer microspheres are The melting point of the sphere is 100-125 DEG C; the nanocellulose and polymer microspheres are prepared by freeze-drying technology to obtain a separator for lithium ion batteries.

[0055] Specifically, the raw material used in the nanocellulose is wood nanocellulose, the raw material of the polymer microsphere is polyethylene microwax emulsion (solid content is 20%), the total solid content of the diaphragm slurry is 10%, and the configuration is 100g The slurry, the specific preparation method is:

[0056] 1) Take an appropriate amount of wood pulp board, use deionized water and ethanol to ultrasonically clean it three times, and after drying, grind it into coarse fibers with a pulverizer. The mass ratio is 1:50. Take the crude fibers a...

Embodiment 2

[0060] Different from Example 1 is the solid content of the polyethylene micro-wax emulsion, the solid content is 5%, that is, according to the actual solid content ratio in the liquid, lignonanocellulose solution: polyethylene micro-wax emulsion: wetting agent: poly The mass ratio of the acrylic glue is 6.93:0.375:0.03:0.04.

[0061] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com