Titanium dioxide coating production system

A production system and technology of titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, fibrous filler, etc., can solve the problems of low production efficiency and large area, and achieve a high degree of automation, small area and production capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

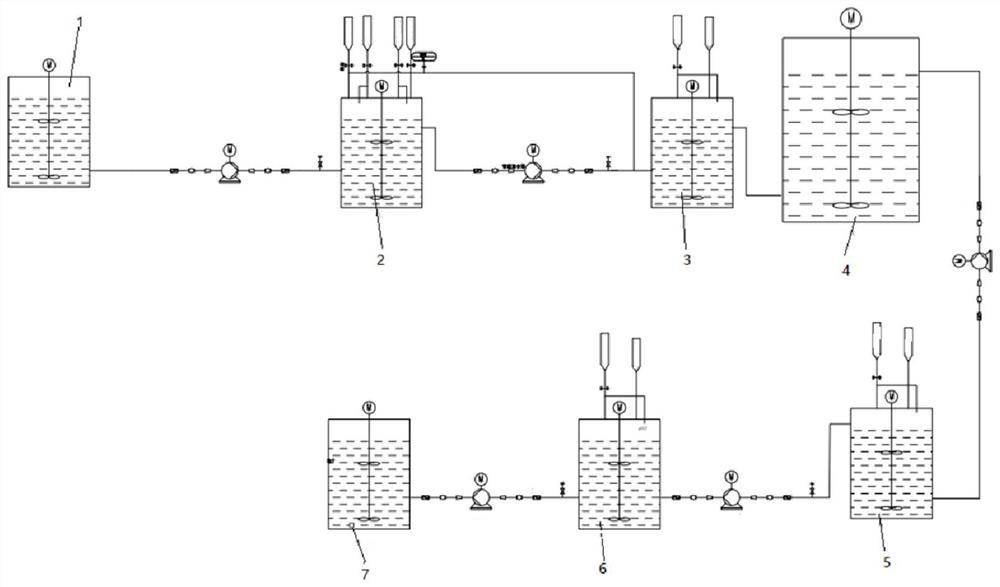

Image

Examples

Embodiment 1

[0040] Continuous coating with low concentration titanium dioxide

[0041] (1) When the titanium dioxide slurry qualified by sand milling is injected into the No. 1 reaction tank, it is configured to be 230g / L, and the feed flow rate is controlled to be 10m 3 / h, feed saturated steam into the No. 1 reaction tank to ensure that the temperature of the slurry is stable at 60°C±2, adjust the pH to 10.5 by adding lye, and the actual measurement of the outlet online specific gravity analyzer is 1.16g / cm 3 , the corresponding concentration is 211.0g / L;

[0042] (2) The slurry in the No. 1 reaction tank is controlled by a pump to have a flow rate of 10m 3 / h into the No. 2 reaction tank, and open the sodium silicate (100g / L) feeding pump at the same time, the flow rate is 0.105m 3 / h, the pH is controlled at 7.5 by adjusting the amount of sulfuric acid added.

[0043] (3) The materials in the No. 2 reaction tank are pumped into the No. 3 reaction tank for aging, and the materials a...

Embodiment 2

[0049] Continuous coating with high concentration titanium dioxide

[0050] (1) When the titanium dioxide slurry qualified by sand milling is injected into the No. 1 reaction, it is configured to be 520g / L, and the feed flow rate is controlled to be 10m 3 / h, feed saturated steam into the No. 1 reactor to ensure that the slurry temperature is stable at 60 ° C ± 2, adjust the pH to 10.5 by adding lye, and the outlet online specific gravity analyzer measured 1.38g / cm 3 , the corresponding concentration is 501.2g / L;

[0051] (2) The slurry in the No. 1 reactor is controlled by a pump to have a flow rate of 10m 3 / h into the No. 2 reactor, and open the sodium silicate (100g / L) feeding pump at the same time, the flow rate is 0.251m 3 / h, the pH is controlled at 7.5 by adjusting the amount of sulfuric acid added.

[0052] (3) The materials in the No. 2 reactor are pumped into the No. 3 reaction tank for aging, and the materials are continuously stirred during this period.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com