Production process of pure-titanium cold-rolled bright-surface titanium belt

A production process and bright surface technology, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of low yield rate, surface quality, poor thermal conductivity of titanium strips, surface bonding of titanium strips, etc., to avoid linear The effect of reducing the production cycle and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

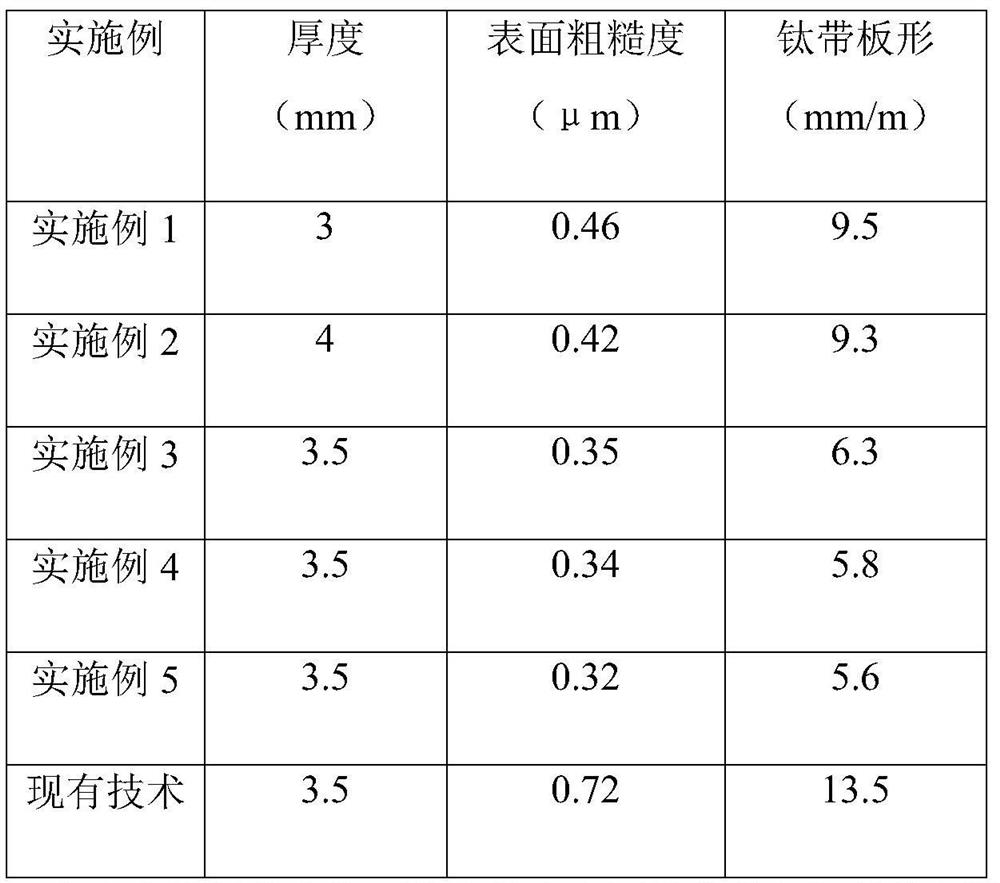

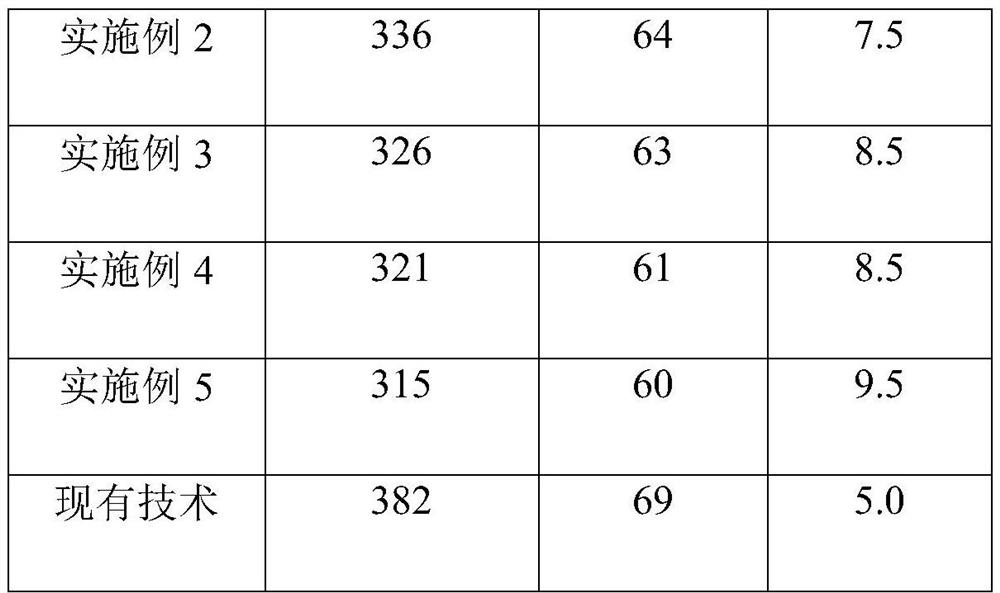

Examples

Embodiment 1

[0034] A pure titanium cold-rolled bright titanium strip production process, comprising the following steps:

[0035] S1, slab hot rolling

[0036] Heat the slab on a heating furnace at a heating temperature of 870°C and a holding time of 260 minutes; then carry out rough rolling and finish rolling in sequence to obtain black-skinned titanium coils;

[0037] The rough rolling adopts a four-high reversible rolling mill; the slab is rolled from 200mm to 35mm, 5 rolling passes, the total deformation is 80%, and the single pass deformation is 16%, to obtain the rough rolling blank;

[0038] The finish rolling adopts a coil finish rolling mill or an eight-stand four-high finish rolling mill; the rough rolling billet is rolled from 35mm to 4.5mm, with a thickness tolerance of -0.20mm, 7 rolling passes, and a total deformation of 83%. The pass deformation is 11.85%, and the final rolling temperature is 700°C;

[0039] S2, black skin titanium coil intermediate annealing and shot bla...

Embodiment 2

[0053] A pure titanium cold-rolled bright titanium strip production process, comprising the following steps:

[0054] S1, slab hot rolling

[0055] Heat the slab on a heating furnace at a heating temperature of 890°C and a holding time of 300 minutes; then carry out rough rolling and finish rolling in sequence to obtain black-skinned titanium coils;

[0056] The rough rolling adopts a four-roll reversible rolling mill; the slab is rolled from 220mm to 40mm, 7 rolling passes, the total deformation is 85%, and the single pass deformation is 12.14%, to obtain the rough rolling blank;

[0057] The finish rolling adopts a coil finish rolling mill or an eight-stand four-high finish rolling mill; the rough rolling billet is rolled from 40mm to 5.5mm, with a thickness tolerance of 0.20mm, 8 rolling passes, and a total deformation of 89%, a single pass The deformation amount is 11.13%, and the final rolling temperature is 705°C;

[0058] S2, black skin titanium coil intermediate anne...

Embodiment 3

[0072] A pure titanium cold-rolled bright titanium strip production process, comprising the following steps:

[0073] S1, slab hot rolling

[0074] Heat the slab on a heating furnace at a heating temperature of 880°C and a holding time of 280 minutes; then carry out rough rolling and finish rolling in sequence to obtain black-skinned titanium coils;

[0075] The rough rolling adopts a four-roll reversible rolling mill; the slab is rolled from 210mm to 38mm, 6 rolling passes, the total deformation is 82%, and the single pass deformation is 13.67%, to obtain the rough rolling blank;

[0076] The finish rolling adopts a coil finish rolling mill or an eight-stand four-high finish rolling mill; the rough rolling billet is rolled from 38mm to 5mm, with a thickness tolerance of 0.15mm, 7 rolling passes, a total deformation of 86%, and a single pass deformation The content is 12.28%, and the final rolling temperature is 735°C;

[0077] S2, black skin titanium coil intermediate annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com