CaSO4 whisker reactor taking desulfurized gypsum as raw material

A desulfurization gypsum and reactor technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of low whisker quality and low production capacity, and achieve the effect of increasing reaction production capacity and improving flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

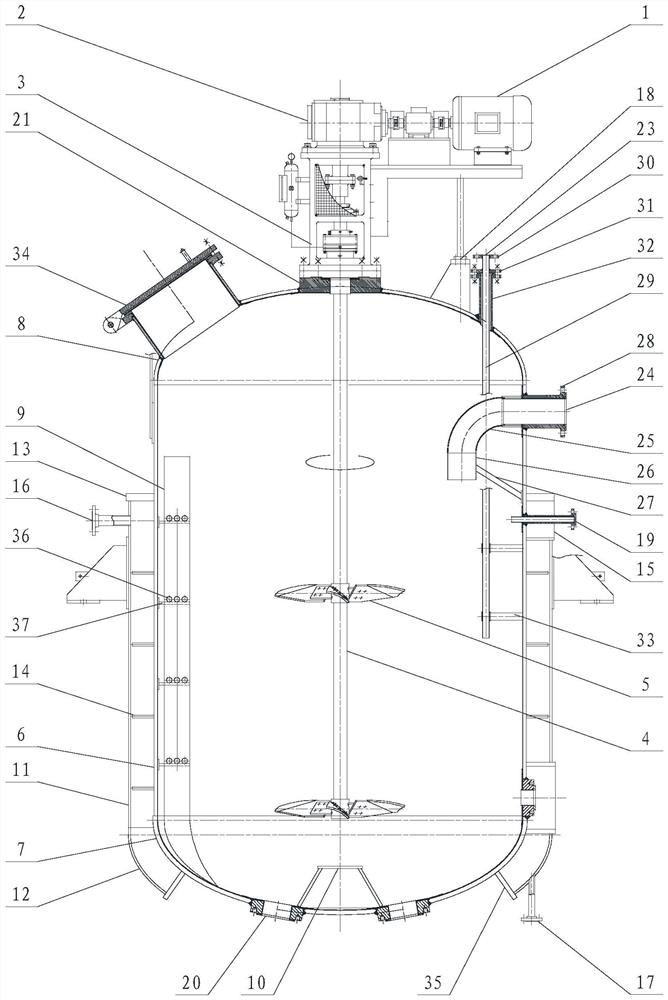

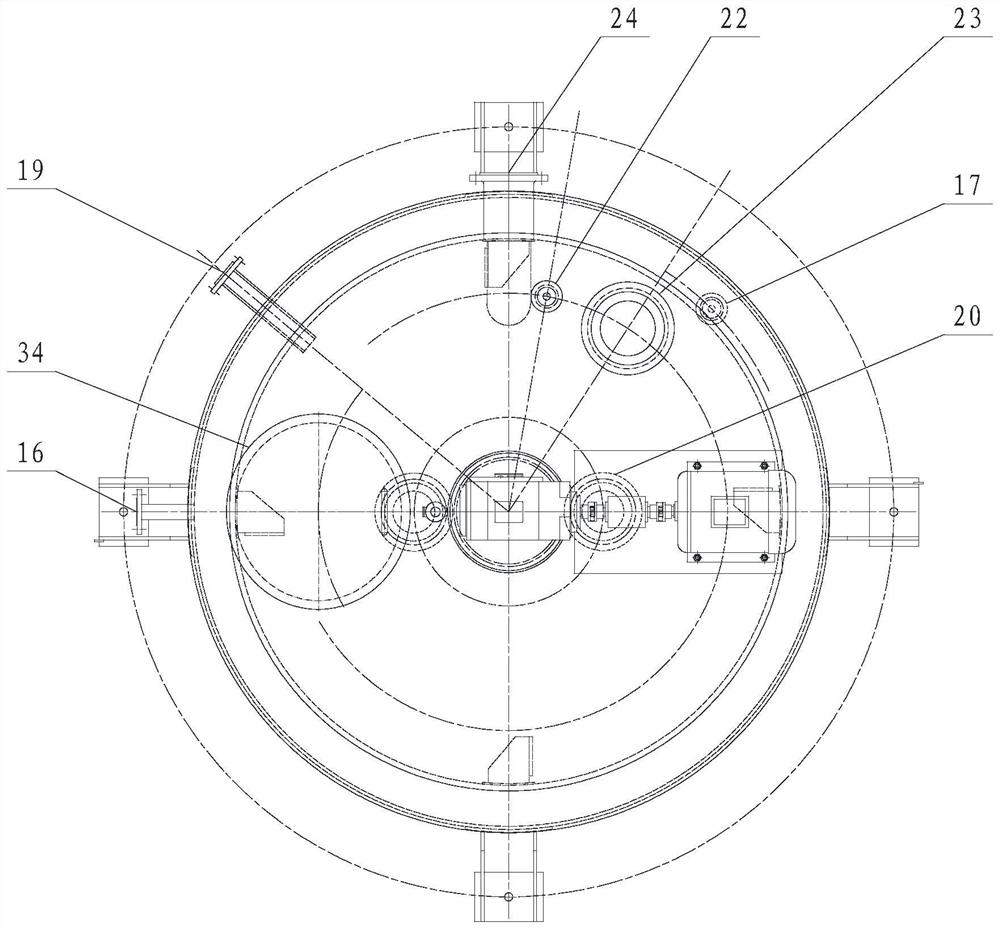

[0025] like figure 1 and figure 2 As shown, the present invention includes a stirrer assembly, an inner container assembly and a heating jacket assembly, wherein the agitator assembly includes a power source, a frame 3, a stirring shaft 4 and a stirring blade 5, the inner container assembly includes a reactor shell, and the reaction The shell of the reactor is respectively provided with a feed port and a discharge flange nozzle 20 which communicate with the inside of the reactor. The heating jacket assembly includes a jacket body 11 and a jacket head 12 .

[0026] The reactor shell of this embodiment includes an inner cylinder 6, a lower head 7 and an upper head 8. The upper and lower ends of the inner cylinder 6 are sealed and welded with the upper head 8 and the lower head 7 respectively. The inner cylinder 6 The inner space of the reactor is enclosed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com