Preparation method of bisphenol (polyphenol) solution in preparation of polycarbonate

A polycarbonate and preparation method technology, which is applied in the field of preparation of bisphenol solution in the process of preparing polycarbonate, can solve the problems of lowering the solution precipitation temperature, increasing side reactions, and increasing temperature, and achieves convenient and simple control of process conditions, and reduces Precipitation temperature, effect of increasing reaction productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

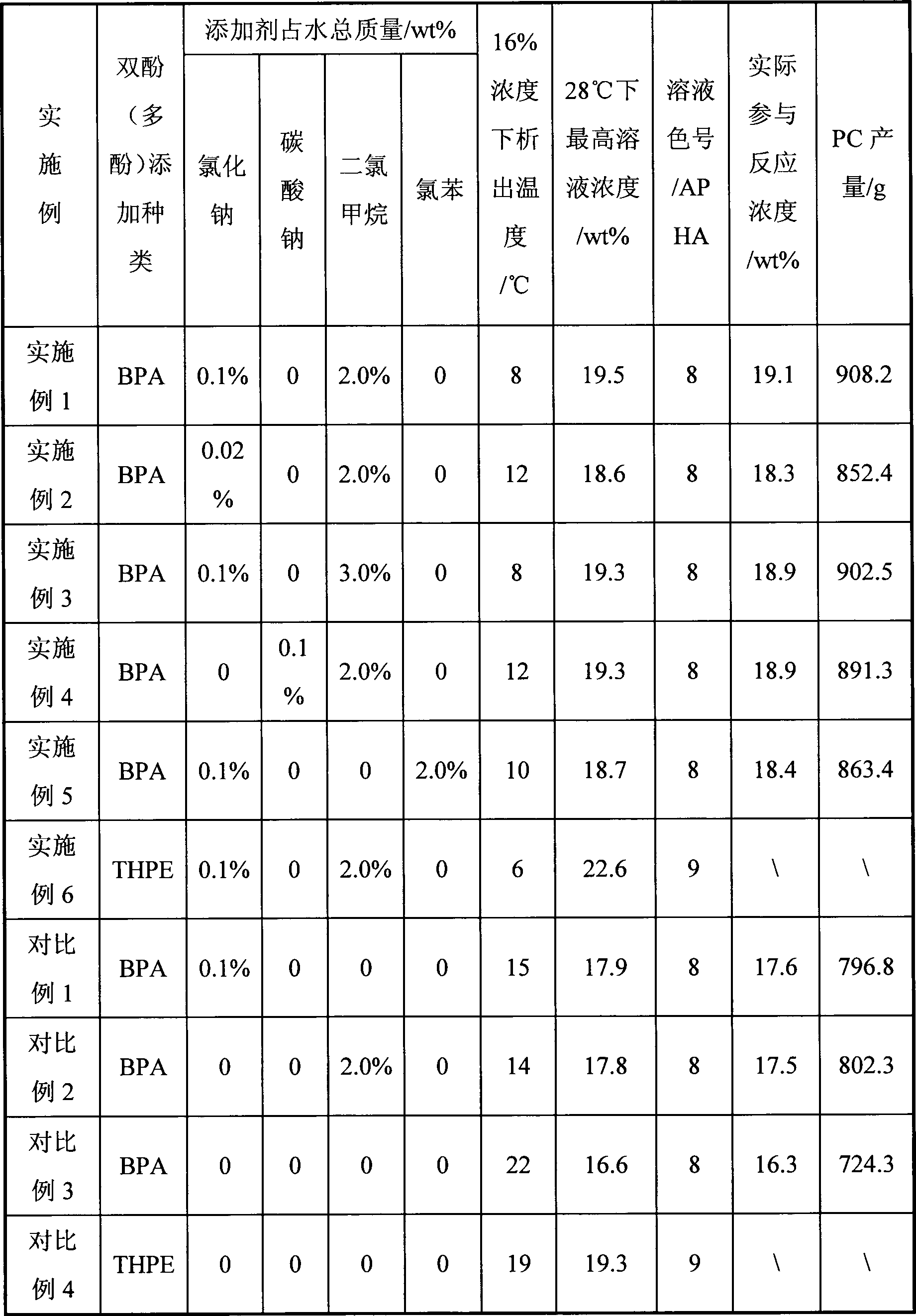

Embodiment 1

[0025]Add 3080g of water, 238g of solid sodium hydroxide and composite additives into the mixing tank to form an alkaline solution. The amount of composite additives added is: 3g of sodium chloride, 60g of methylene chloride, and then 645g of bisphenol A (BPA) is added to the solution For the powder, fully stir to dissolve, gradually lower the temperature until solid precipitates appear, and record the temperature before the precipitation. The above method was used to reconfigure the BPA sodium salt solution and control the solution temperature to 28°C. Continuously add BPA and NaOH to the BPA solution in units of 5gBPA and 1.8gNaOH until solid precipitation occurs, record the total amount of BPA added before precipitation and measure the solution color number (APHA). Using the above method, add 3080g of water, 300g of solid sodium hydroxide and composite additives into the mixing tank to form an alkaline solution. The amount of composite additives added is: 3g of sodium chlor...

Embodiment 2

[0027] Add 3080g of water, 238g of solid sodium hydroxide and compound additives into the mixing tank to form an alkaline solution. The amount of compound additives added is: 0.6g of sodium chloride and 60g of dichloromethane, and then add 645g of BPA powder into the solution and stir thoroughly Dissolve, gradually lower the temperature until solid precipitates appear, record the temperature before the precipitation. The above method was used to reconfigure the BPA sodium salt solution and control the solution temperature to 28°C. Continuously add BPA and NaOH to the BPA solution in units of 5gBPA and 1.8gNaOH until solid precipitation occurs, record the total amount of BPA added before precipitation and measure the solution color number (APHA). Using the above method, add 3080g of water, 282g of solid sodium hydroxide and composite additives into the mixing tank to form an alkaline solution. The amount of composite additives added is: 0.6g of sodium chloride, 60g of methylene...

Embodiment 3

[0029] Add 3080g of water, 240g of solid sodium hydroxide and compound additives into the mixing tank to form an alkaline solution. The amount of compound additives added is: 3g of sodium chloride and 92g of dichloromethane, and then add 650g of BPA powder into the solution, fully stir to dissolve , gradually lower the temperature until solid precipitates appear, and record the temperature before the precipitation. The above method was used to reconfigure the BPA sodium salt solution and control the solution temperature to 28°C. Continuously add BPA and NaOH to the BPA solution in units of 5gBPA and 1.8gNaOH until solid precipitation occurs, record the total amount of BPA added before precipitation and measure the solution color number (APHA). Using the above method, add 3080g of water, 298g of solid sodium hydroxide and composite additives into the mixing tank to form an alkaline solution. The amount of composite additives added is: 3g of sodium chloride and 92g of dichlorome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com