High-solid-content high-dispersity proton exchange membrane fuel cell catalyst ink and preparation method thereof

A proton exchange membrane, catalyst ink technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high viscosity catalyst ink with high solid content, poor catalyst dispersion effect, etc., to facilitate preparation, improve dispersion effect, and facilitate stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

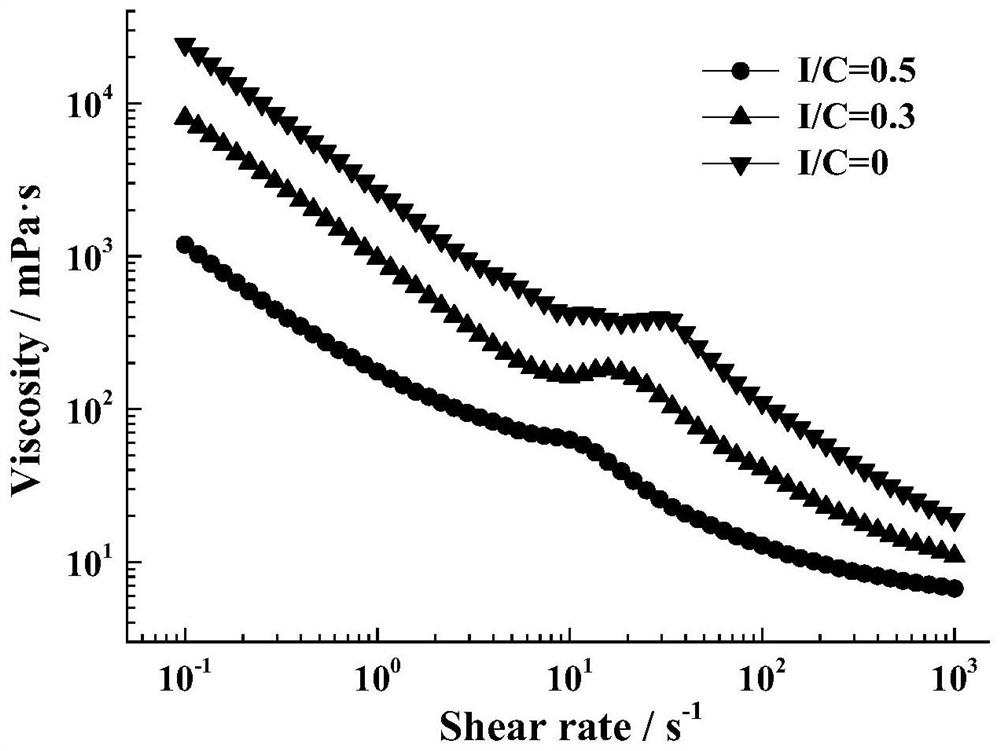

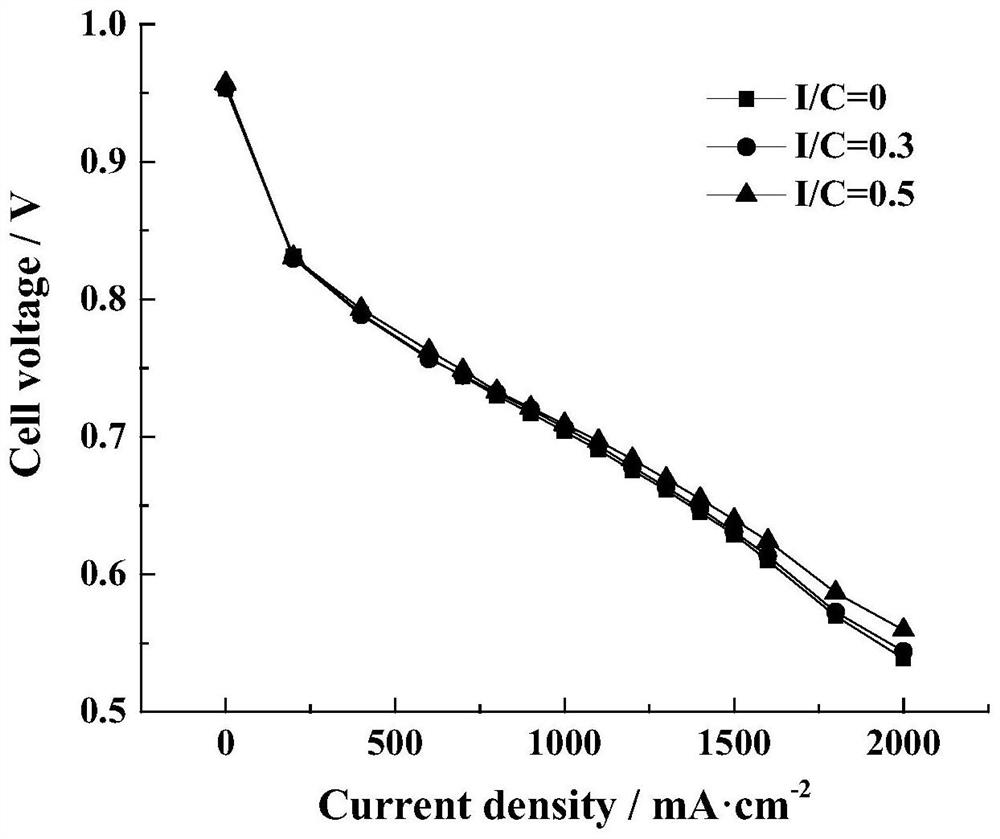

Embodiment 1

[0037] This embodiment provides a catalyst ink for a proton exchange membrane fuel cell with high solid content and high dispersion. The catalyst ink is composed of a solute and a solvent, and the mass ratio of the solute is 15%. The solute is a Pt / C catalyst, the first The ionomer and the second ionomer, the ratio of the total mass of the first ionomer and the second ionomer to the mass of activated carbon in the Pt / C catalyst is 1:1, and the mass ratio of the first ionomer to activated carbon was 0.5 (I / C=0.5). The solvent in the catalyst ink is a mixture of water, ethanol and n-propanol, and water accounts for 50% of the total mass of the solvent.

[0038] The preparation process of the catalyst ink is as follows:

[0039] 1) After the catalyst was wetted with water, the first ionomer solution (D79) was added, and pre-dispersed by stirring at a low speed with a rotation speed of 3000 rpm and a dispersion time of 2 hours to obtain a pre-dispersed ink.

[0040] 2) Use a hom...

Embodiment 2

[0044] Compared with Example 1, most of them are the same, except that in this embodiment, the mass ratio of the first ionomer and activated carbon is 0.5 (I / C=0.5) into the mass of the first ionomer and activated carbon The ratio was 0.3 (I / C=0.3).

Embodiment 3

[0046]Compared with Example 1, most of them are the same, except that in this example, the mass proportion of the solute in the catalyst ink is changed to 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com