Extraction and separation method of multiple components of ganoderma lucidum and application of extraction and separation method in preparation of artificially planted ganoderma lucidum extract

A separation method and multi-component technology, which can be applied to medical preparations containing active ingredients, plant raw materials, pharmaceutical formulations, etc., can solve the problems of low extraction efficiency, inability to prepare high-quality artificial Ganoderma lucidum products, and low extraction purity of Ganoderma lucidum polysaccharides. , to achieve the effect of improving extraction purity, improving biological safety and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

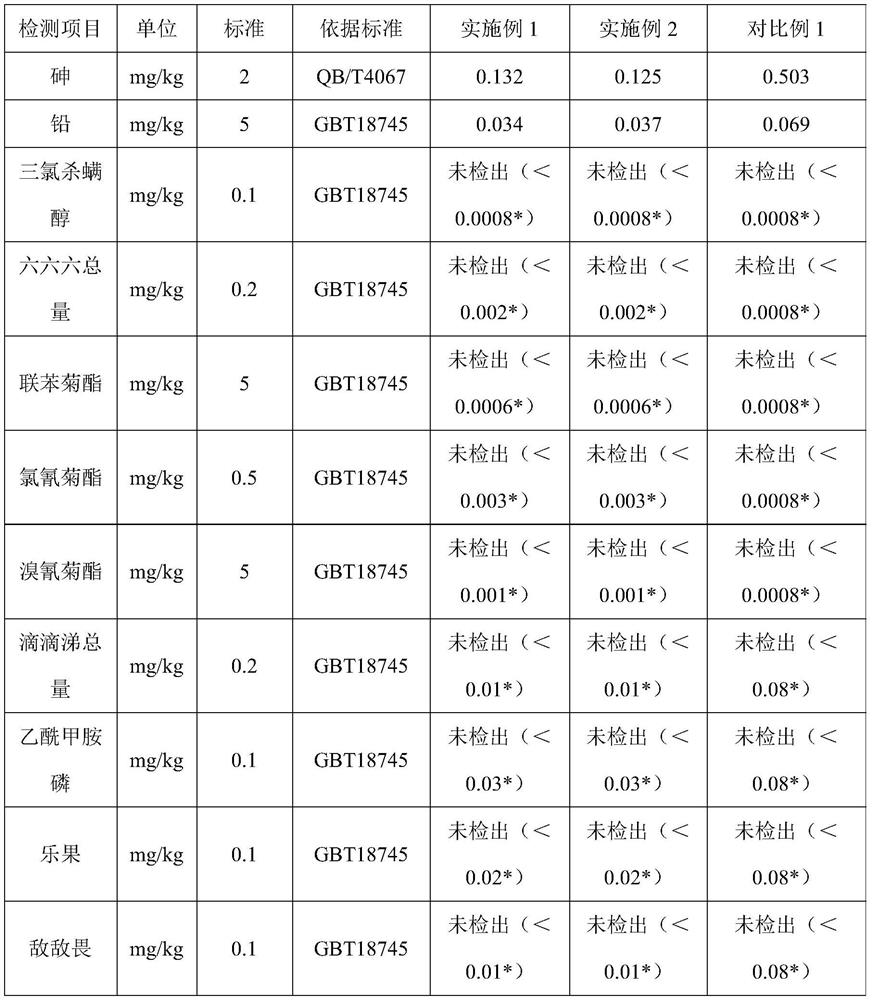

Examples

Embodiment 1

[0049] A method for extracting and separating ganoderma multi-components, comprising the steps of:

[0050] The ganoderma lucidum is crushed and then extracted, and the extract is separated in multiple stages to obtain a ganoderma polysaccharide enrichment and a ganoderma triterpene enrichment.

[0051] The specific operation is as follows:

[0052] 1. Crushing (crushing): crush 5Kg of Ganoderma lucidum, and then crush it until it can pass through a 30-mesh sieve;

[0053]2. Feeding: Take 5Kg of mixed raw materials as a batch of feeding, put it into the feeding tank, add 100L hot water according to the ratio of material to water of 1:20, make the temperature of the material liquid at 60°C, and stir evenly;

[0054] 3. Extraction: transport the feed liquid to the extraction and breaking unit for extraction, and the extraction cycle time is 18 minutes;

[0055] 4. Centrifugation: centrifuge the material extract, the frequency of the main centrifuge is 42.0Hz, the frequency of ...

Embodiment 2

[0061] A preparation method of artificial Ganoderma lucidum combined with instant Ganoderma lucidum essence:

[0062] Wild Ganoderma lucidum was extracted according to the extraction and separation method of multi-components of Ganoderma lucidum in the above-mentioned embodiment 1, and multi-stage separation was carried out to obtain Ganoderma lucidum polysaccharide enrichment and Ganoderma triterpene enrichment;

[0063] Extract the artificial Ganoderma lucidum according to the method for extracting and separating the multi-components of Ganoderma lucidum in the above-mentioned embodiment 1, and obtain the Ganoderma lucidum polysaccharide enrichment and Ganoderma triterpene enrichment through multi-stage separation;

[0064] The Ganoderma lucidum polysaccharide enrichment and the Ganoderma triterpene enrichment of the artificial Ganoderma lucidum are blended according to the mass ratio of the Ganoderma lucidum polysaccharide enrichment and the Ganoderma triterpene enrichment i...

Embodiment 3

[0066] A method for extracting and separating ganoderma multi-components, comprising the steps of:

[0067] The Ganoderma lucidum is crushed and then extracted, and the extract is separated in multiple stages to obtain Ganoderma lucidum polysaccharide enrichment and Ganoderma triterpene enrichment.

[0068] The specific operation is as follows:

[0069] 1. Crushing (crushing): crush 5Kg of Ganoderma lucidum, and then crush it until it can pass through a 30-mesh sieve.

[0070] 2. Feeding: Take 5Kg of mixed raw materials as a batch of feeding, put it into the feeding tank, add 100L hot water according to the ratio of material to water of 1:20, keep the temperature of the material liquid at 80°C, and stir evenly.

[0071] 3. Extraction: The material liquid is transported to the extraction and breaking unit for extraction, and the extraction cycle time is 20 minutes.

[0072] 4. Centrifugation: Centrifuge the material extract, the frequency of the main centrifuge is 42.0Hz, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com