Electric pulse auxiliary machining device for machining slender shaft parts and machining method of electric pulse auxiliary machining device

A part processing and auxiliary processing technology, applied in the field of mechanical processing, can solve the problems of insufficient surface roughness and geometric accuracy, and achieve excellent chatter and deformation, prolong service life, and suppress chatter and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

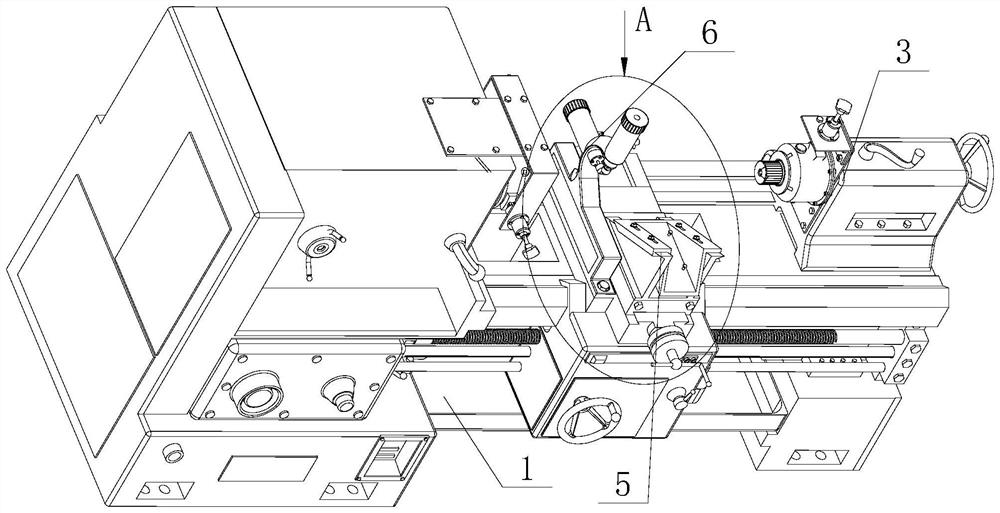

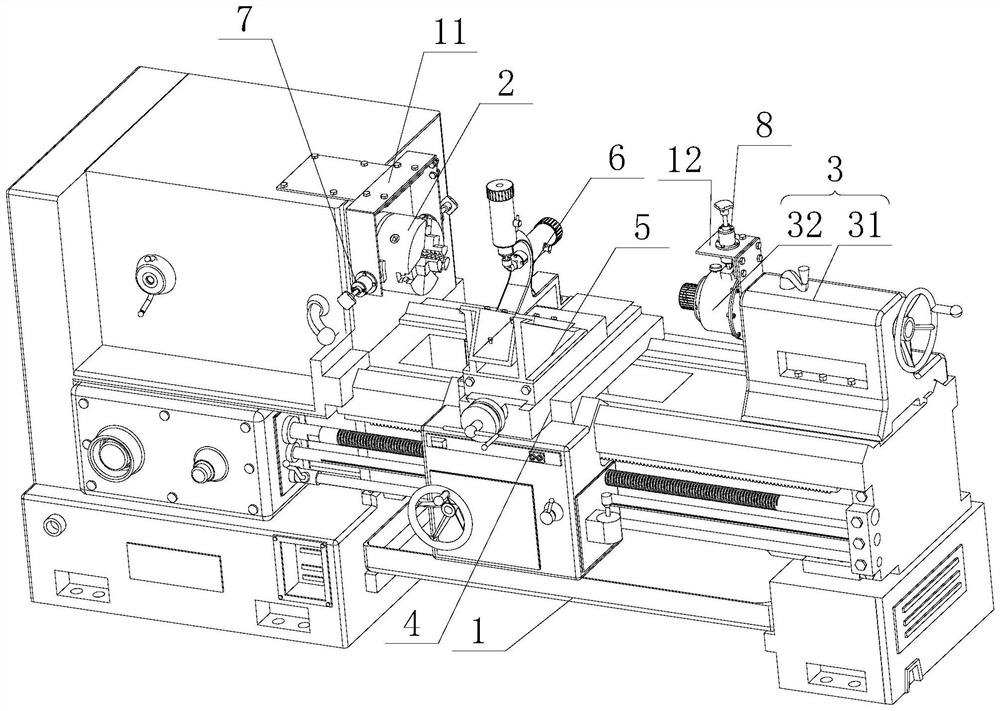

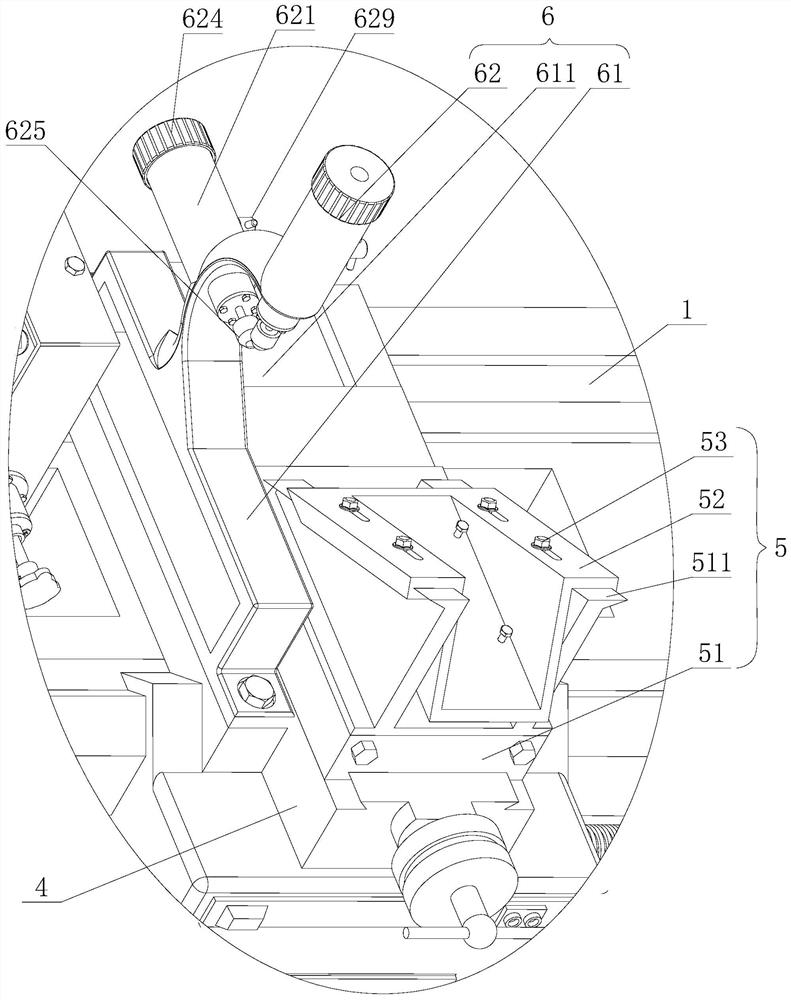

[0038] Figure 1 to Figure 8 An embodiment of the electric pulse auxiliary processing device for processing slender shaft parts of the present invention is shown. The electric pulse auxiliary processing device for processing slender shaft parts includes a machine tool 1, and the front and rear ends of the machine tool 1 are respectively provided with clamps. The disc mechanism 2 and the tensioned tailstock 3, the machine tool 1 is provided with a slide box 4 between the chuck mechanism 2 and the tensioned tailstock 3, and the slide box 4 is provided with a tool mounting frame 5 and a tool holder 6 , the chuck mechanism 2 is provided with a chuck power connection mechanism 7, and the tension type tailstock 3 is provided with a tailstock power connection mechanism 8, and the chuck power connection mechanism 7 and the tailstock power connection mechanism 8 are connected with the positive pole and the negative pole of the pulse power supply. Respectively connected, the tool rest 6...

Embodiment 2

[0056] An electric pulse assisted processing method for processing slender shaft parts, which is carried out by using the electric pulse assisted processing device for processing slender shaft parts in Embodiment 1, comprising the following steps:

[0057] Step S1, installation of slender shaft parts: fasten one end of the slender shaft parts to the chuck mechanism 2 on the machine tool 1, and tighten the other end to the tensioned tailstock 3. Specifically, one end of the slender shaft part is clamped on the chuck mechanism 2 on the machine tool 1, and the other end is clamped on the clamping mechanism 34 of the tensioned tailstock 3. Next, the axial tension force is formed on the slender shaft parts.

[0058] Step S2, radial support of slender shaft parts: adjust the position of the tool rest 6, make the slender shaft parts pass through the space 611, and then make each magnetorheological damping support assembly 62 radially support the slender shaft parts , the magneto-rhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com