Surface polishing treatment system for grey ink cast iron platform

A cast iron platform and surface polishing technology, which is used in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. problems, to achieve the effect of simplifying work steps and improving polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

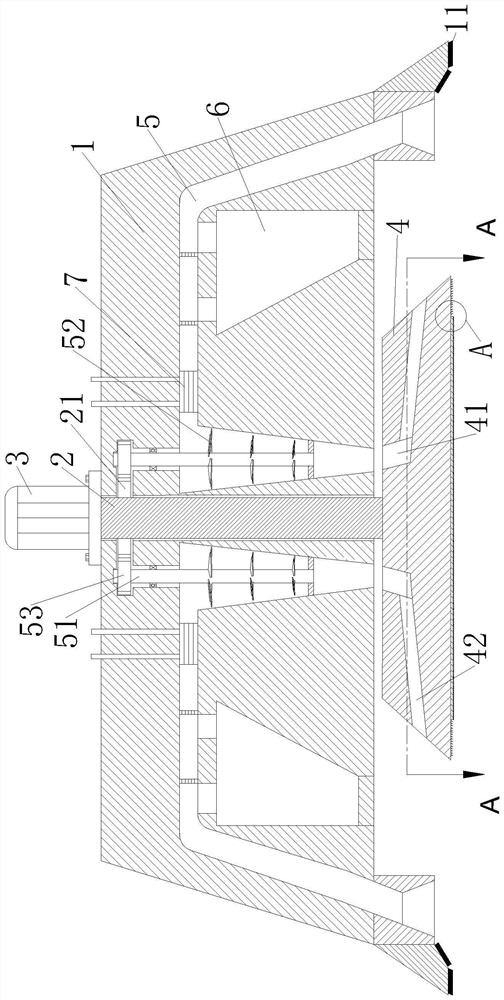

[0044] As a specific embodiment of the present invention, a brush 11 is provided on the side surface of the body 1 .

[0045] By being provided with a brush 11 on the side surface of the body 1, on the one hand, during the polishing process, the brush 11 can pre-clean the part to be polished to prevent impurities on the surface of the platform from affecting the polishing quality; on the other hand, the brush 11 Fixedly connected around the side surface of the machine body 1, when the polishing disc 4 is performing polishing work, the brush 11 has been in contact with the table top, thus the brush 11 forms a closed area on the periphery of the polishing disc 4, and the waste debris produced by the polishing disc 4 It plays a blocking role to prevent waste chips from flying randomly on the surface of the platform, and it is inconvenient for the ventilation pipe groove 5 to collect it.

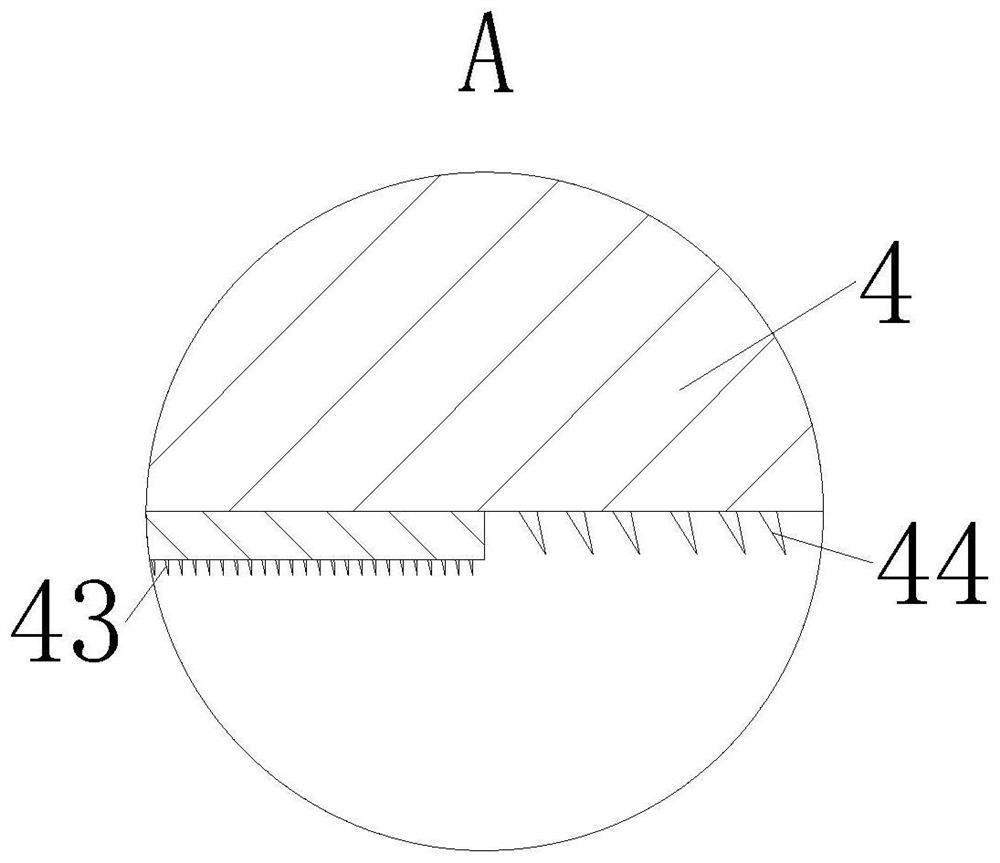

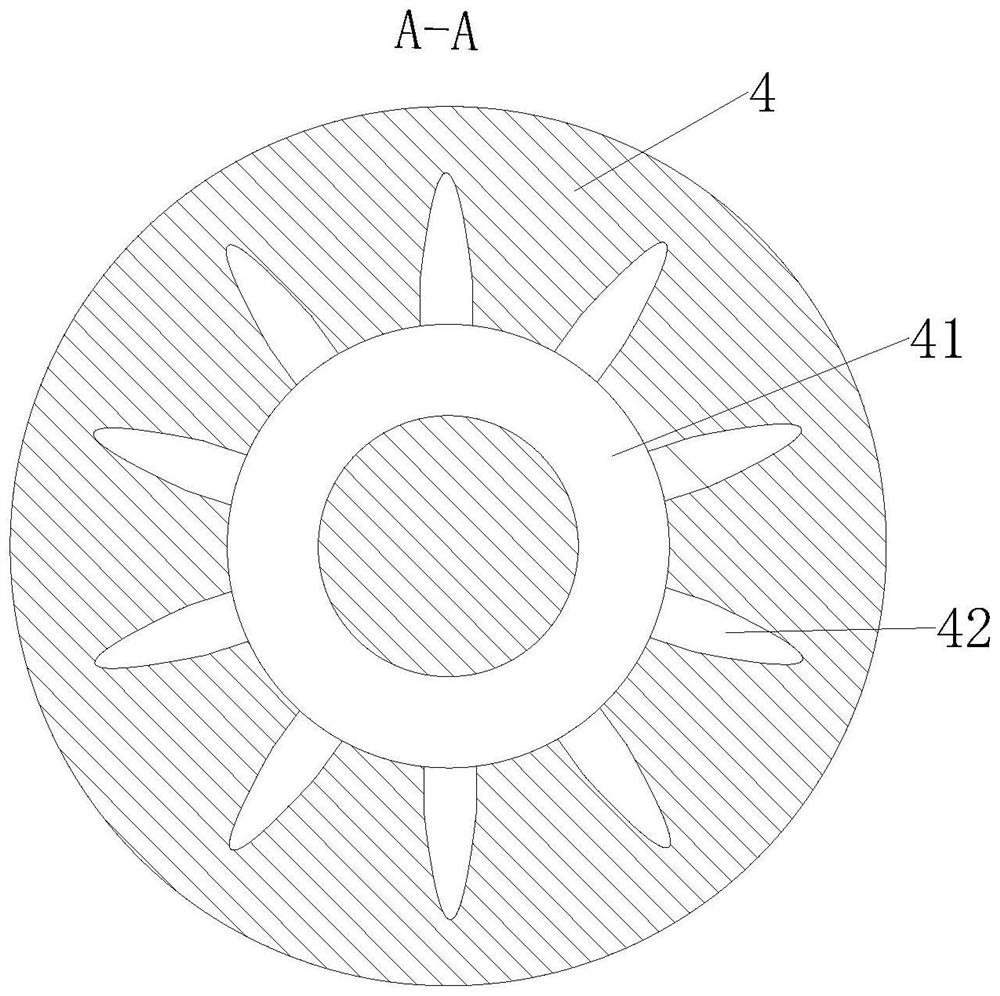

[0046] As a specific embodiment of the present invention, a circular boss is provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com