Method for purifying crude vanadium oxytrichloride

A technology of vanadium oxychloride and oxygen, applied in chemical instruments and methods, vanadium halide, vanadium compounds, etc., can solve the problem that impurities cannot be effectively removed, and achieve the effect of high popularization and application value, low cost and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

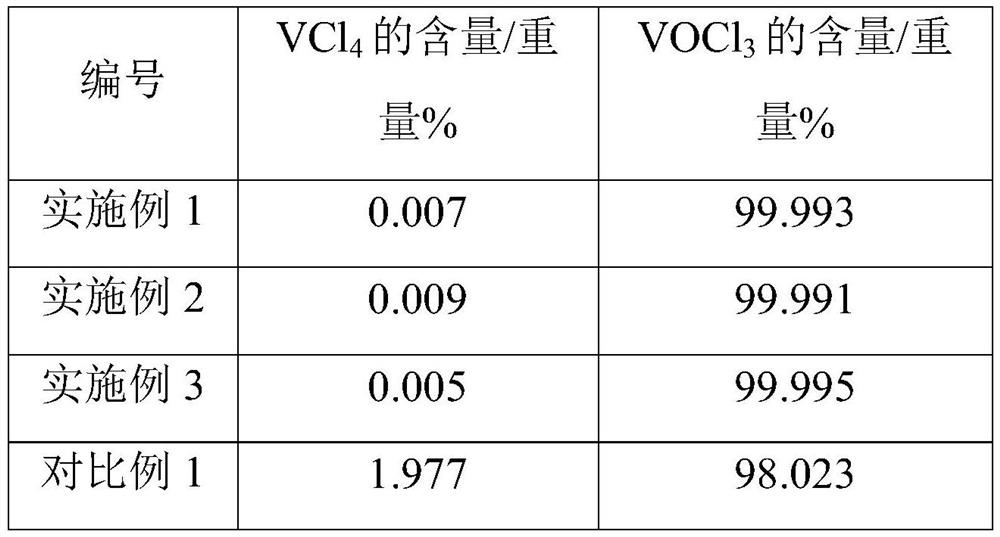

Embodiment 1

[0040] (1) Place 100g of crude vanadyl trichloride in a polytetrafluoro flask with magnetic stirring function. The flask contains an air inlet and a condensation return pipe made of polytetrafluoroethylene. 4 The content is 1.003% by weight, VOCl 3 The content is 98.997% by weight, and the oxygen that feeds 0.5L / min purity into the flask is 99.99%, under the condition of condensation reflux (condensation reflux operation adopts dehydrated alcohol as condensation medium, and the temperature of condensation medium is-5 ℃ ), contact the crude vanadyl trichloride with oxygen and react at 100°C (the reaction is carried out under the condition of magnetic stirring, and the speed of magnetic stirring is 200r / min), after reacting for 5h, stop feeding oxygen and stop magnetic stirring; The tail gas produced by condensation reflux is absorbed and purified by 25% by weight of NaOH aqueous solution;

[0041] (2) the condensing reflux tube is replaced with a condensing tube made of polyte...

Embodiment 2

[0043] (1) Place 150g of crude vanadyl trichloride in a polytetrafluoro flask with magnetic stirring function. The flask contains an air inlet and a condensation return pipe made of polytetrafluoroethylene. 4 The content is 3.304% by weight, VOCl 3 The content is 96.696% by weight, and the oxygen of 99.99% is passed into the purity of 1.5L / min in the flask, under the condition of condensation reflux (condensation reflux operation adopts dehydrated alcohol as condensation medium, and the temperature of condensation medium is-15 ℃ ), contact the crude vanadyl trichloride with oxygen and react at 150°C (reaction is carried out under the condition of magnetic stirring, and the speed of magnetic stirring is 300r / min), after reacting for 3h, stop feeding oxygen and stop magnetic stirring; The tail gas produced by condensation reflux is absorbed and purified by 25% by weight of NaOH aqueous solution;

[0044] (2) Replace the condensing reflux tube with a condensing tube made of poly...

Embodiment 3

[0046] (1) Place 200g of crude vanadyl trichloride in a polytetrafluoro flask with magnetic stirring function. The flask contains an air inlet and a condensation return pipe made of polytetrafluoroethylene. 4 The content is 4.951% by weight, VOCl 3 The content is 95.049% by weight, and the oxygen of 2L / min purity is 99.99% is passed into the flask, under the condition of condensation reflux (condensation reflux operation adopts dehydrated alcohol as condensation medium, and the temperature of condensation medium is-20 ℃) , contact the crude vanadyl trichloride with oxygen to react at 180°C (the reaction is carried out under the condition of magnetic stirring, and the speed of magnetic stirring is 500r / min), after reacting for 2h, stop feeding oxygen, stop magnetic stirring; The tail gas produced by reflux is absorbed and purified by 25% by weight of NaOH aqueous solution;

[0047] (2) Replace the condensing reflux tube with a condensing tube made of polytetrafluoroethylene, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com