Preparation method and application of polypyrrole/poly-zwitterionic conductive hydrogel

A polyzwitterion, conductive hydrogel technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement and other directions, can solve the problems of complex production process by soaking method, achieve green environmental protection of raw materials, wide application scenarios, large stretching rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

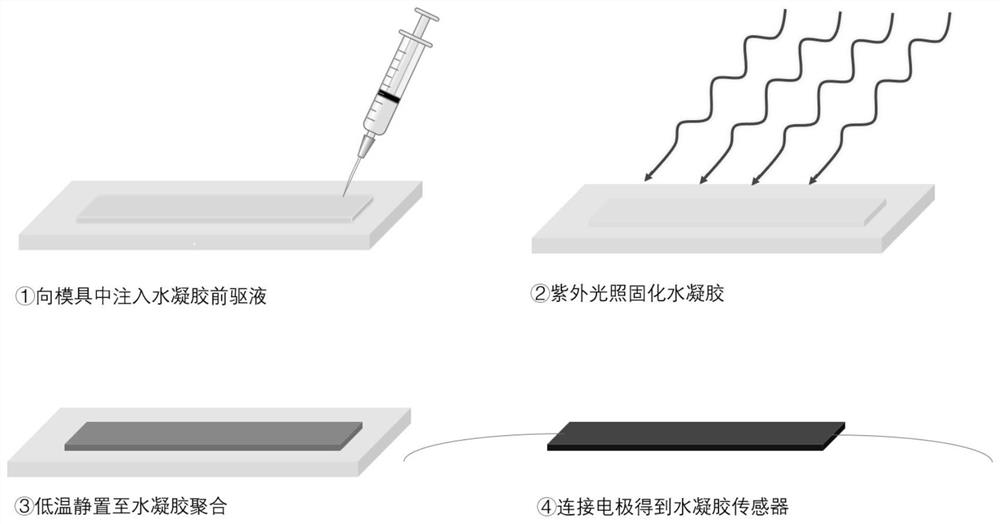

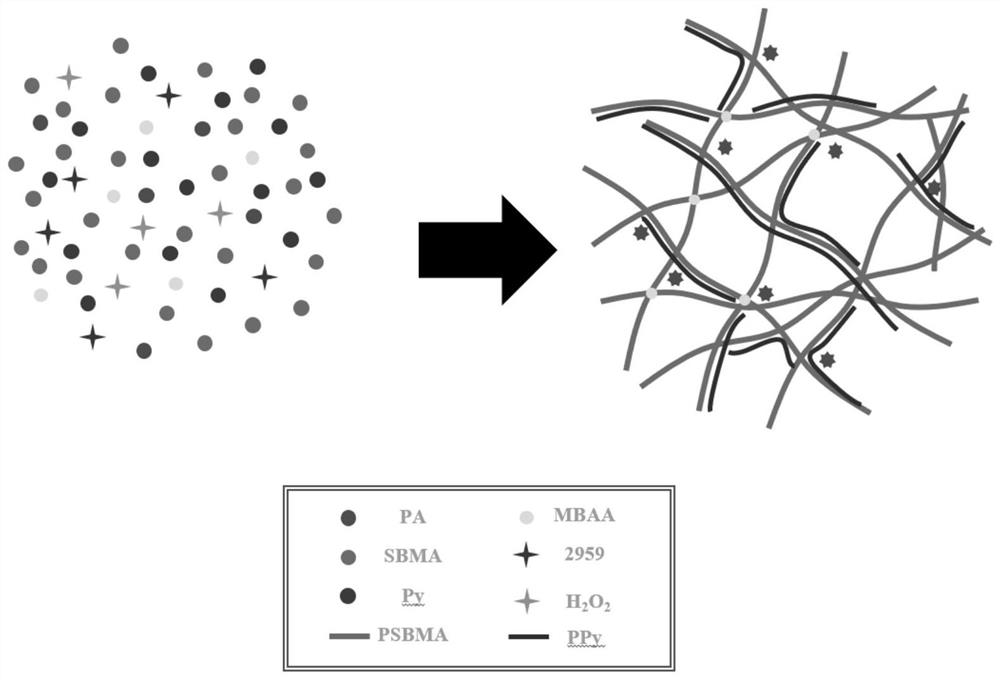

[0036] 1) Dissolve 800mg [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammonium hydroxide in 1118μL deionized water and stir until completely dissolved, then add 6mgN,N - Methylenebisacrylamide, 16mg2959 photoinitiator ultrasonic cleaning to disperse in the solution, then add 33mg 50% phytic acid solution and 10mg pyrrole monomer, mix thoroughly and store in a refrigerator at 4°C.

[0037] 2) Add 16.9 mg of 30% hydrogen peroxide to the solution when in use, and mix thoroughly to obtain a hydrogel precursor.

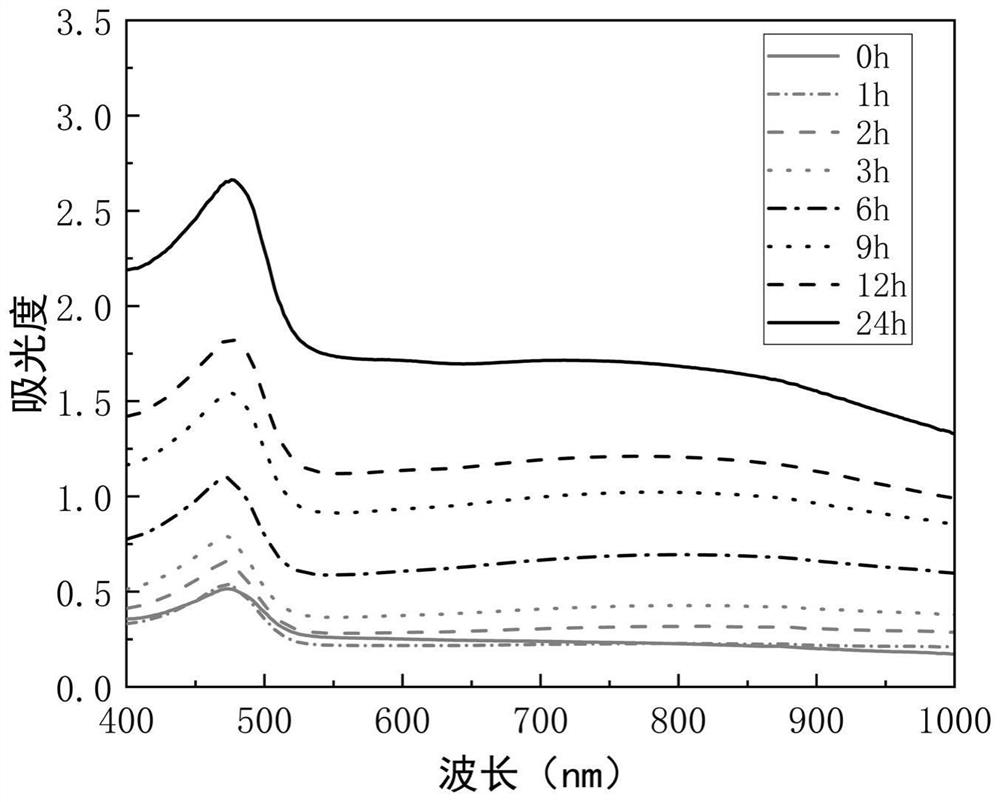

[0038] 3) Pour the hydrogel precursor solution into a mold with a groove of 10mm×40mm×3mm, cover with a glass sheet to isolate oxygen, put it into a 4°C low-temperature storage box for 12 hours after being exposed to ultraviolet light for 15 minutes, and obtain Polypyrrole / Polyzwitterionic Conductive Hydrogel.

Embodiment 2

[0040] 1) Dissolve 800mg [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammonium hydroxide in 1058μL deionized water and stir until completely dissolved, then add 6mgN,N - Methylenebisacrylamide, 16mg2959 photoinitiator ultrasonic cleaning to disperse in the solution, then add 66mg 50% phytic acid solution and 20mg pyrrole monomer, mix thoroughly and store in a refrigerator at 4°C.

[0041] 2) Add 33.8 mg of 30% hydrogen peroxide to the solution when used, and mix thoroughly to obtain a hydrogel precursor.

[0042] 3) Pour the hydrogel precursor solution into a mold with a groove of 10mm×40mm×3mm, cover with a glass sheet to isolate oxygen, put it into a 4°C low-temperature storage box for 12 hours after being exposed to ultraviolet light for 15 minutes, and obtain Polypyrrole / Polyzwitterionic Conductive Hydrogel.

Embodiment 3

[0044] 1) Dissolve 800mg [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammonium hydroxide in 998μL deionized water and stir until completely dissolved, then add 6mgN,N - Methylenebisacrylamide, 16mg2959 photoinitiator ultrasonic cleaning to disperse in the solution, then add 99mg 50% phytic acid solution and 30mg pyrrole monomer, mix well and store in a refrigerator at 4°C.

[0045] 2) Add 50.7 mg of 30% hydrogen peroxide to the solution during use, and mix thoroughly to obtain a hydrogel precursor.

[0046] 3) Pour the hydrogel precursor solution into a mold with a groove of 10mm×40mm×3mm, cover with a glass sheet to isolate oxygen, put it into a 4°C low-temperature storage box for 12 hours after being exposed to ultraviolet light for 15 minutes, and obtain Polypyrrole / Polyzwitterionic Conductive Hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com